Nano-silicon-modified double-component wear-resistant penetration hardener and preparation method thereof

A hardener and two-component technology, which is applied in the field of nano-silicon modified two-component wear-resistant penetrating hardener and its preparation, can solve the problem of poor storage stability of one-component silicone resin penetrating hardener, water-based silicate Penetrating hardener takes a long time to take effect, and silane treatment agents have weak strengthening effects, etc., to achieve excellent performance, transparent and colorless appearance, and achieve the effect of strengthening modification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

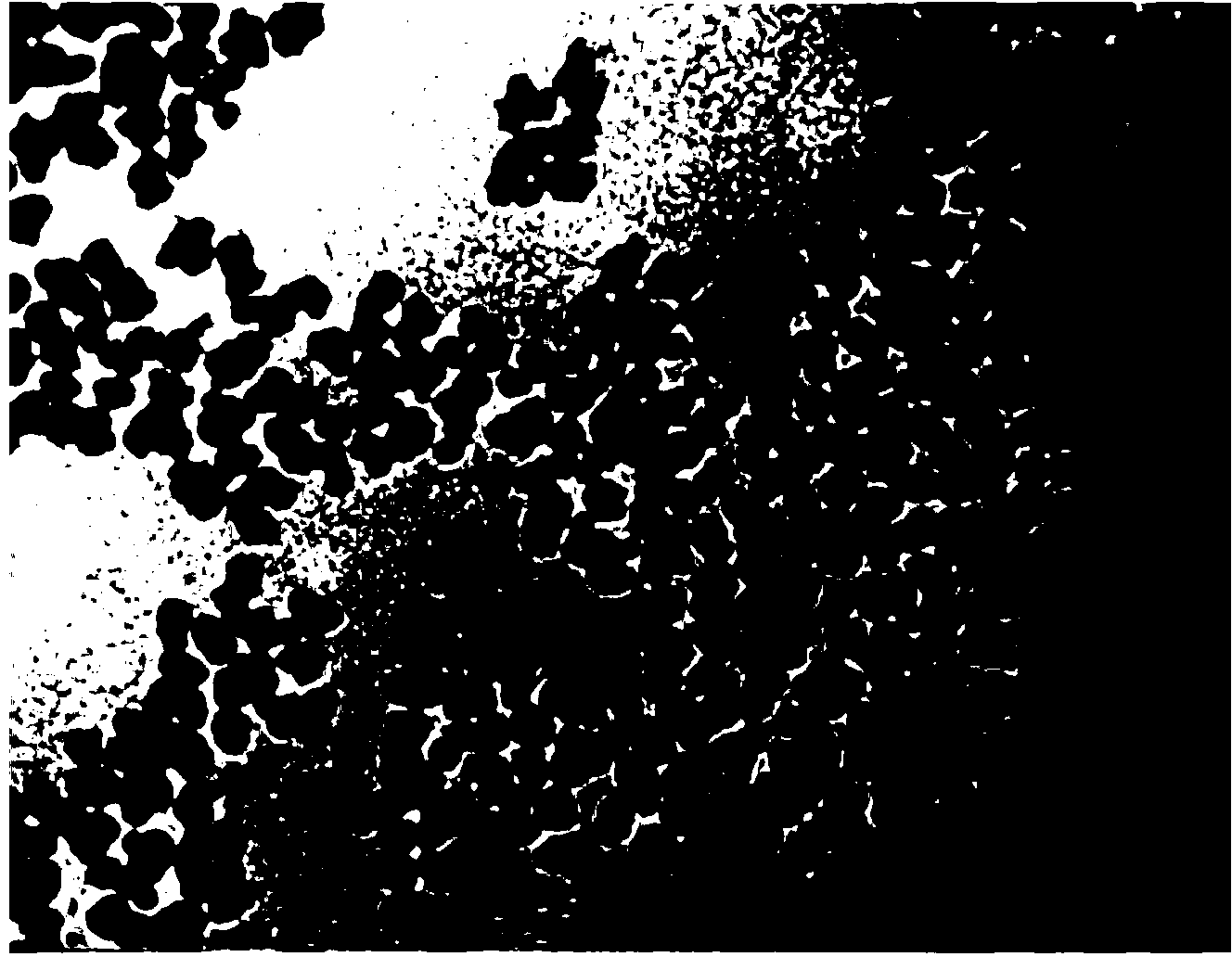

Image

Examples

Embodiment Construction

[0037] The present invention will be described in detail below in conjunction with specific embodiments. It should be understood that these examples are used to illustrate the present invention and not to limit the scope of the present invention. The implementation conditions not indicated in the examples are generally the conditions in routine experiments.

[0038] The preparation method of the nano-silicon modified two-component wear-resistant penetrating hardener of the present invention includes the preparation process of two components A and B respectively:

[0039] (1) The preparation method of component A includes two steps of siloxane prepolymerization and wear resistance modification:

[0040] Siloxane prepolymerization:

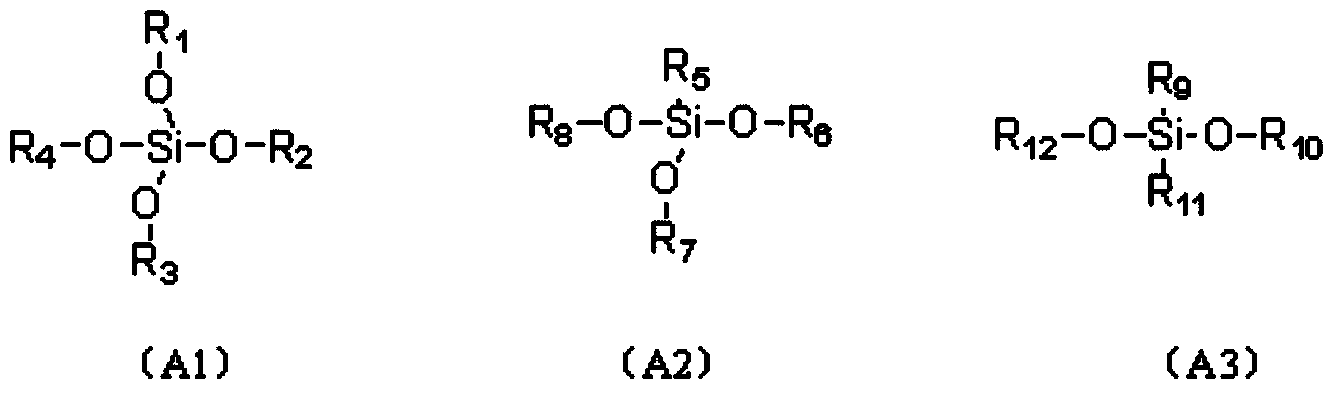

[0041] At least one of the siloxane (A1) with four functional linkages and the siloxane (A2) with trifunctional linkages, or the siloxane (A1) with four functional linkages, the siloxane with trifunctional linkages At least one of the siloxanes (...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com