A kind of processing method of nitrile rubber production waste water

A technology for producing wastewater and nitrile rubber, which is applied in the fields of water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc. Affect the processing effect, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0015] In the present invention, in step a, as long as the acrylonitrile in the nitrile rubber production wastewater is reduced as far as possible, there is no special requirement on the amount of borohydride, preferably, the amount of borohydride is 2-5g. According to a preferred embodiment of the present invention, the borohydride is sodium borohydride and / or potassium borohydride.

[0016] In step a, as long as the purpose of the present invention can be achieved by using aluminum chloride while using borohydride, there is no special requirement on the amount of aluminum chloride, and the consumption of aluminum chloride is preferably 20-100mg / L acrylonitrile-butadiene rubber Produce waste water. The inventors of the present invention found that the use of the above-mentioned preferred amount of aluminum chloride can more effectively remove the acrylonitrile contained in the nitrile rubber production wastewater by catalytic reduction, so that it cannot cause harm to microor...

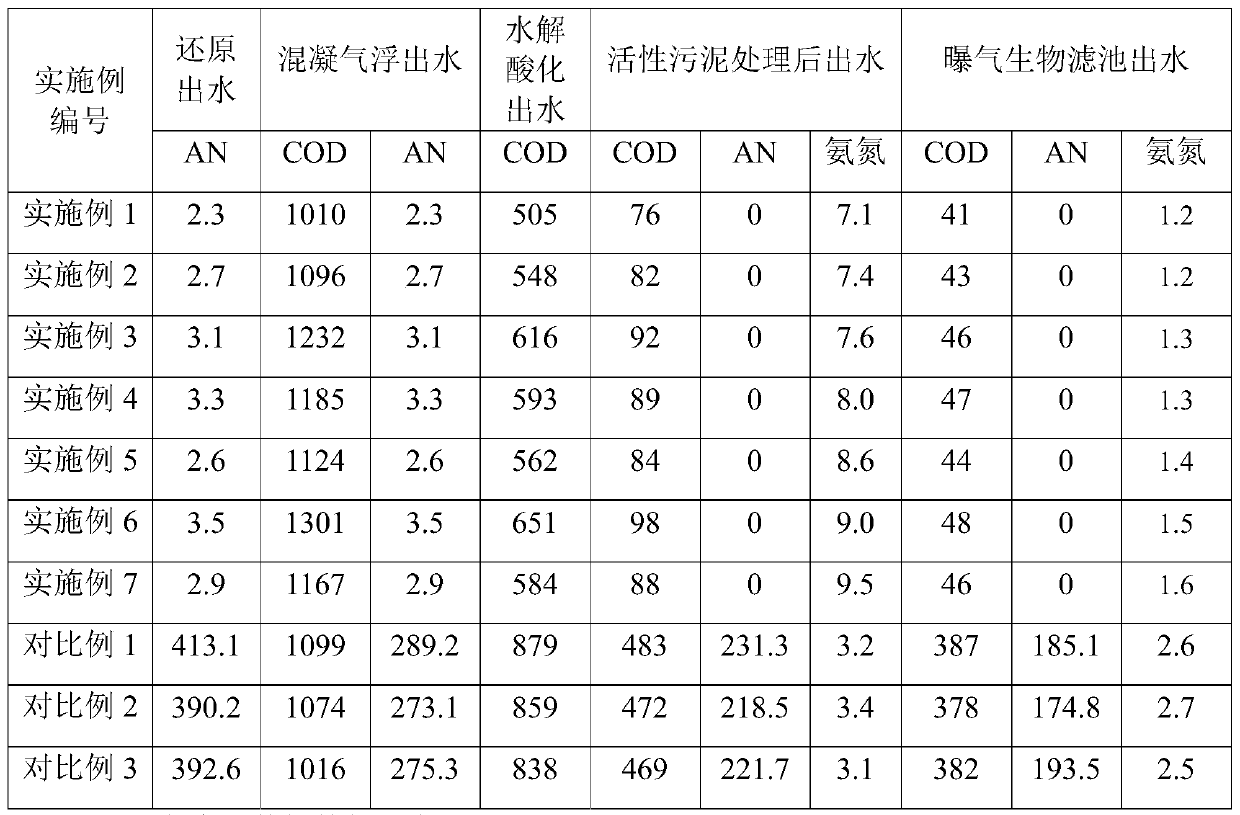

Embodiment 1

[0028] Adjust the pH value of wastewater 1 to 10.0, add sodium borohydride and aluminum chloride to it, so that the concentrations in the wastewater are 1.84g / L and 65mg / L respectively, and the reaction time is 80min; the above-mentioned effluent enters the coagulation gas Floating unit, add polyacrylamide so that the concentration in the wastewater is 2.5mg / L, the hydraulic retention time is 30min, and the surface hydraulic load is 6m 3 / (m 2 h); the above-mentioned effluent enters the hydrolysis acidification unit, the dissolved oxygen is controlled to be 0.15mg / L, and the hydraulic retention time is 7h; the above-mentioned effluent enters the activated sludge treatment unit, the activated sludge concentration is 3000mg / L, and the dissolved oxygen is 2mg / L, The hydraulic retention time is 14h; the above-mentioned effluent enters the biological aerated filter, the dissolved oxygen is 3mg / L, and the volume load is 0.35kg COD / m 3 d. See Table 2 for the processing results.

Embodiment 2

[0036] Adjust the pH value of wastewater 2 to 10.5, add potassium borohydride and aluminum chloride to it, so that the concentrations in the wastewater are 1.91g / L and 80mg / L respectively, and the reaction time is 70min; the above-mentioned effluent enters the coagulation gas Floating unit, add cationic polyacrylamide so that the concentration in the wastewater is 3.0mg / L, the hydraulic retention time is 25min, and the surface hydraulic load is 7m 3 / (m 2 h); the above-mentioned effluent enters the hydrolysis acidification unit, the dissolved oxygen is controlled to be 0.1mg / L, and the hydraulic retention time is 5h; the above-mentioned effluent enters the activated sludge treatment unit, the concentration of activated sludge is 3500mg / L, and the dissolved oxygen is 4mg / L. The hydraulic retention time is 16h; the above effluent enters the biological aerated filter, the dissolved oxygen is 4mg / L, and the volume load is 0.25kg COD / m 3 d. See Table 2 for the processing results....

PUM

| Property | Measurement | Unit |

|---|---|---|

| chemical oxygen demand (mass) | aaaaa | aaaaa |

| turbidity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com