Strong-flavor rice arrack and manufacturing method thereof

A production method and a strong aroma technology, applied in the field of winemaking, can solve the problems of unstable quality, different flavor components, less aroma components, etc., and achieve the effects of rich flavor, stable quality, and stable quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

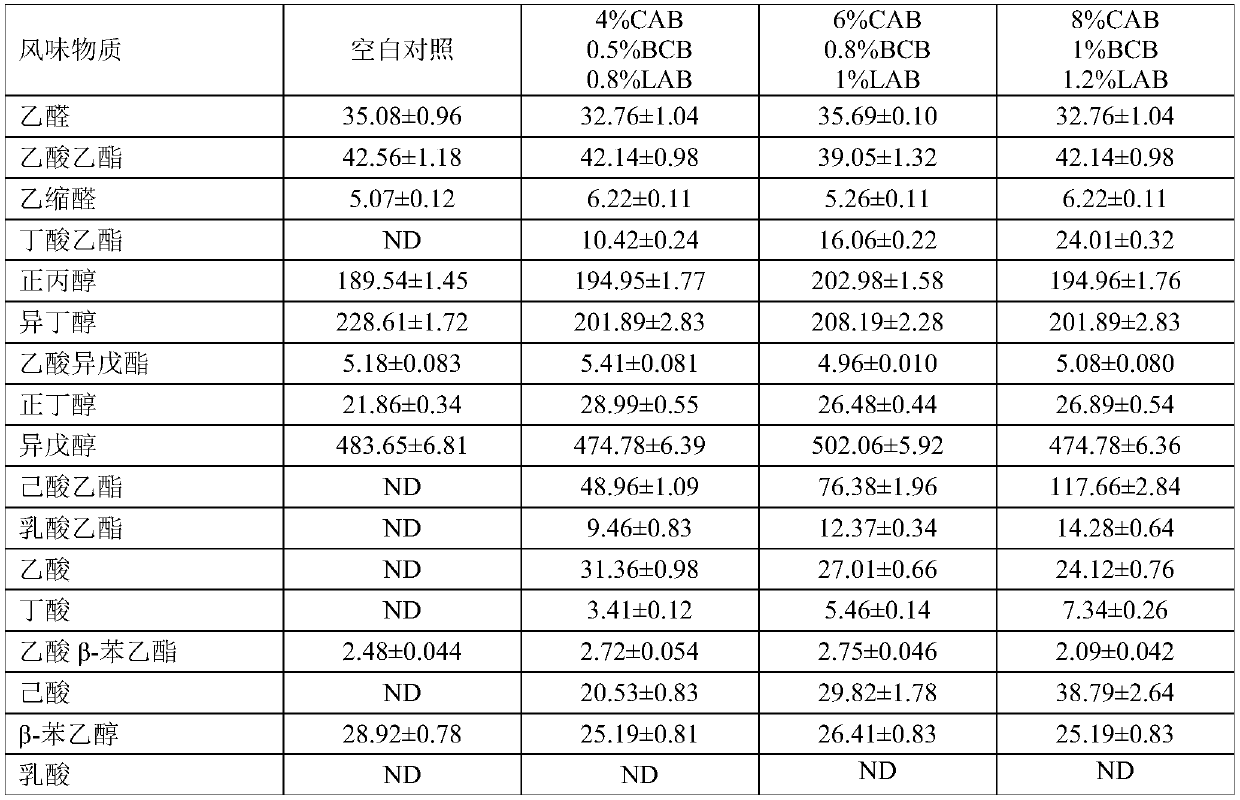

Embodiment 1

[0036] (1) Preparation of fermentation strain

[0037] Culture yeast strains for fermentation at 30°C for 2 days; caproic acid bacteria at 34°C for 10 days under anaerobic conditions; butyric acid bacteria at 37°C for 2 days under anaerobic conditions; lactic acid bacteria at 34°C for 1 day sky;

[0038] (2) Fermentation of Luzhou-flavored rice shochu

[0039] After the rice is soaked and cooked to get cooked rice, add 0.1% rhizopus koji by rice weight, add 120% sterilized water, add 1% saccharomyces, add 4%, 0.5%, 0.8% caproic acid bacteria, Ding Acid bacteria and lactic acid bacteria, controlled temperature at 25°C for 15 days of fermentation, shaking once a day to obtain fermented mature mash;

[0040] (3) Distillation of fragrant rice shochu

[0041] The fermented mash is distilled. The distillate is collected in sections, and the distillation is stopped when the volume of the distillate reaches 30% of the mash volume, and the part of the distillate with an alcohol con...

Embodiment 2

[0044] (1) Preparation of fermentation strain

[0045] Culture yeast strains for fermentation at 28°C for 2 days; caproic acid bacteria at 34°C for 12 days under anaerobic conditions; butyric acid bacteria at 37°C for 2 days under anaerobic conditions; lactic acid bacteria at 34°C for 2 days sky;

[0046] (2) Fermentation of Luzhou-flavored rice shochu

[0047]After the rice is soaked and cooked to obtain cooked rice, add 0.15% rhizopus koji by weight of the rice, add 110% sterilized water, add 1.5% yeast, add 6%, 0.8%, 1% caproic acid bacteria, Ding Acid bacteria and lactic acid bacteria, controlled temperature at 25°C for 13 days of fermentation, shaking once a day to obtain fermented mature mash;

[0048] (3) Distillation of fragrant rice shochu

[0049] The fermented mash is distilled. The distillate is collected in sections, and the distillation is stopped when the volume of the distillate reaches 30% of the mash volume, and the part of the distillate with an alcohol ...

Embodiment 3

[0052] (1) Preparation of fermentation strain

[0053] Culture yeast strains for fermentation at 25°C for 3 days; caproic acid bacteria at 34°C for 14 days under anaerobic conditions; butyric acid bacteria at 37°C for 3 days under anaerobic conditions; lactic acid bacteria at 34°C for 2 days sky;

[0054] (2) Fermentation of Luzhou-flavored rice shochu

[0055] After the rice is soaked and cooked to get cooked rice, add 0.2% rhizopus koji by weight of the rice, add 100% sterilized water, add 2% yeast, add 8%, 1%, 1.2% caproic acid bacteria, Ding Acid bacteria and lactic acid bacteria were fermented at 28°C for 12 days under controlled temperature and shaken once a day to obtain fermented mature mash.

[0056] (3) Distillation of fragrant rice shochu

[0057] The fermented mash of rice wine is distilled. The distillate is collected in sections, and the distillation is stopped when the volume of the distillate reaches 30% of the mash volume, and the part of the distillate wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com