Salt-thickened water-soluble branched polymer as well as preparation method and application thereof

A branched polymer, water-soluble technology, used in chemical instruments and methods, drilling compositions, etc., can solve problems such as limited improvement ability, and achieve the effect of stable product performance and high shear resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0065] Embodiment 1, preparation salt thickening type water-soluble branched polymer

[0066] (1) Preparation of zwitterionic monomers: 12g of 4-vinylpyridine and 10g of 13-propane sultone were reacted with 2g of hydrochloric acid, the reaction temperature was 80°C, and the reaction time was 8 hours to prepare VPPS (Formula I);

[0067] (2) Dissolve 71gAM and 12gVPPS in 400g H 2 O, mechanical stirring, passing condensed water, passing N 2 ; warm up to 45°C, inject CeCl 3 30mg, react for 1.5 hours;

[0068] (2) Inject 5.4mg HPG and add 30mg CeCl 3 , reacted for 1.5 hours, and kept at 45°C;

[0069] (3) Add 2g AM and 1gVPPS, add 2g of fluorocarbon amphiphilic surfactant, and react for 1.5 hours;

[0070] (4) Place the reactor in an oven at 80°C for 4 hours.

[0071] (5) Take out the reactor, add 16.0g NaOH into it, pass condensed water, stir mechanically, and hydrolyze at 140°C for 2 hours.

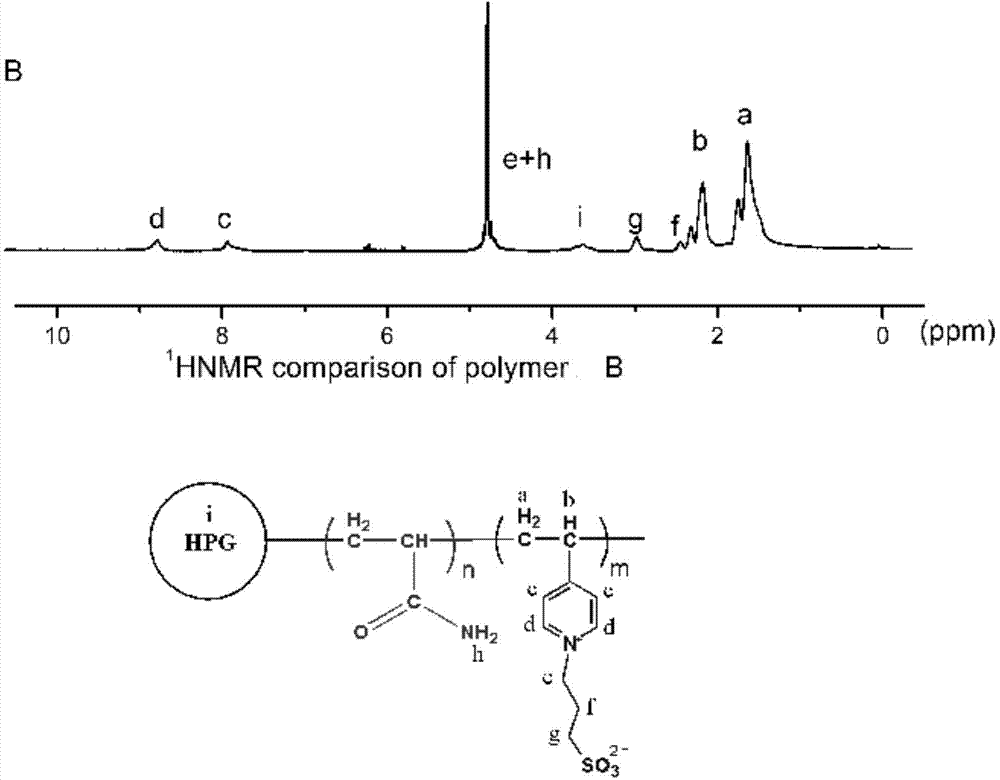

[0072] The salt-thickening type water-soluble branched polymer proton nuclear ma...

Embodiment 2

[0075] Embodiment 2, preparation salt thickening type water-soluble branched polymer

[0076] (1) Preparation of zwitterionic monomers: 14g of vinylpyridine and 14g of 1,3-propane sultone were reacted with 4g of hydrochloric acid, the reaction temperature was 90°C, and the reaction time was 6 hours to prepare VPPS through ring-opening polymerization;

[0077] (2) Dissolve 68gAM and 16gVPPS in 390g H 2 O, mechanical stirring, passing condensed water, passing N 2 ; warm up to 50°C, inject CeCl 3 40mg, react for 2 hours;

[0078] (3) Inject 5.0mg HPG and add 40mg CeCl 3 , reacted for 2 hours, and kept at 50°C;

[0079] (4) Add 3g AM and 1.5g VPPS, add 3g of fluorocarbon amphiphilic surfactant, and react for 2 hours;

[0080] (5) Place the reactor in an oven at 90°C for 6 hours.

[0081] (6) Take out the reactor, add 16.8g NaOH into it, pass condensed water, stir mechanically, and hydrolyze at 120°C for 4 hours.

[0082] The water-soluble branched polymer proton nuclear mag...

Embodiment 3

[0085] Embodiment 3, preparation salt thickening type water-soluble branched polymer

[0086] (1) Preparation of zwitterionic monomers: 16g of vinylpyridine and 14g of 1,3-propane sultone were reacted with 4g of hydrochloric acid, the reaction temperature was 90°C, and the reaction time was 7 hours to prepare VPPS through ring-opening polymerization;

[0087] (2) Dissolve 72g AM and 14g VPPS in 400g H 2 O, mechanical stirring, passing condensed water, passing N 2 ; warm up to 48°C, inject CeCl 3 35mg, react for 2 hours;

[0088] (3) Inject 6.0mg HPG and add 35mg CeCl 3 , reacted for 1.5 hours, and kept at 48°C;

[0089] (4) Add 2.5gAM1.25gVPPS, add 2.5g of fluorocarbon amphiphilic surfactant, and react for 1.5 hours;

[0090] (5) Place the reactor in an oven at 85°C for 5 hours.

[0091] (6) Take out the reactor, add 17g NaOH into it, pass condensed water, stir mechanically, and hydrolyze at 130°C for 3 hours.

[0092] The water-soluble branched polymer proton nuclear m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com