Plasticizing system of conveying belt production line

A production line and conveyor belt technology, which is applied in the field of equipment for producing belts, can solve the problems of large energy consumption, hidden dangers, and low product level, and achieve the effects of improving heat exchange efficiency, safe and reliable production, and stable product performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

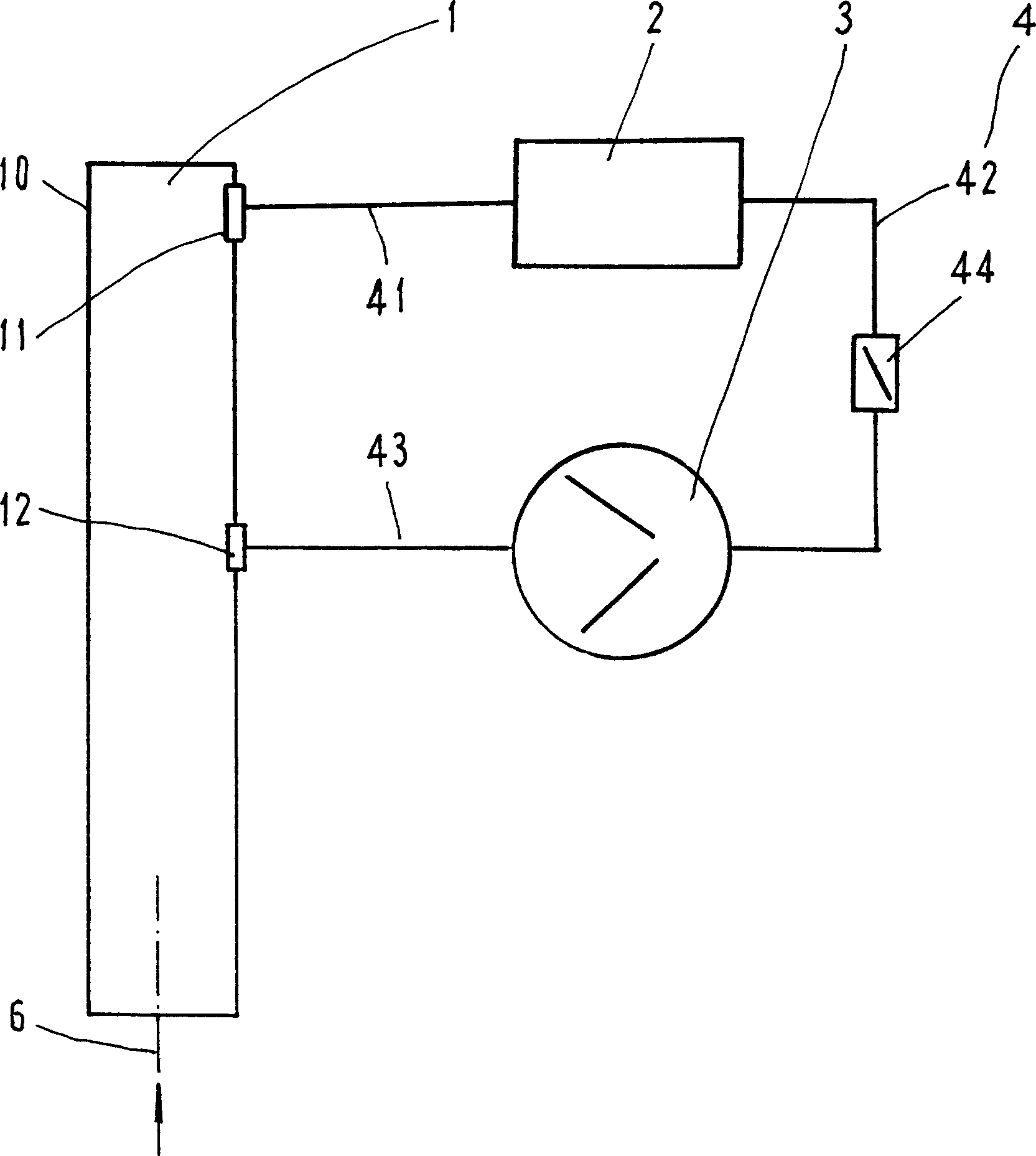

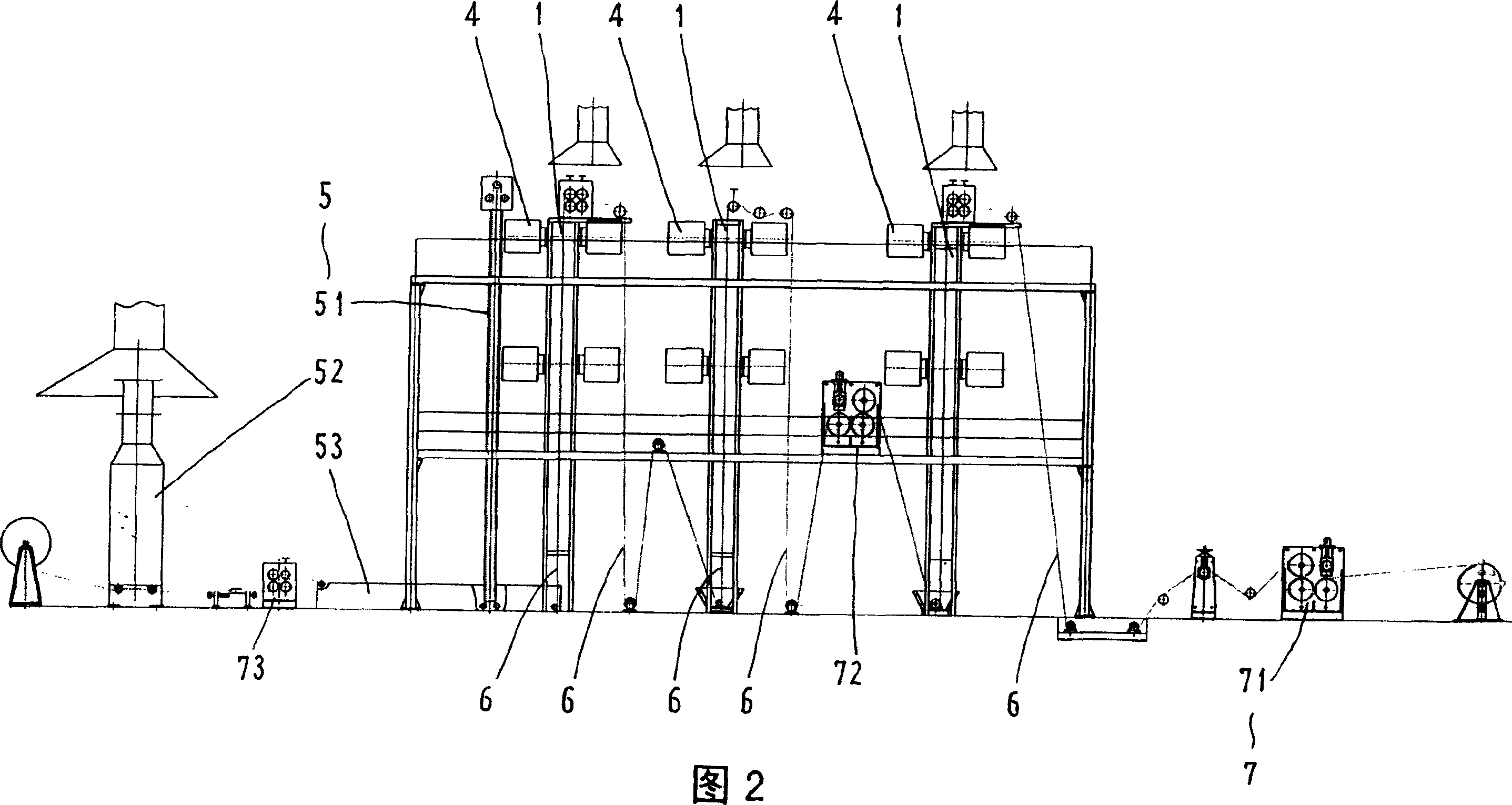

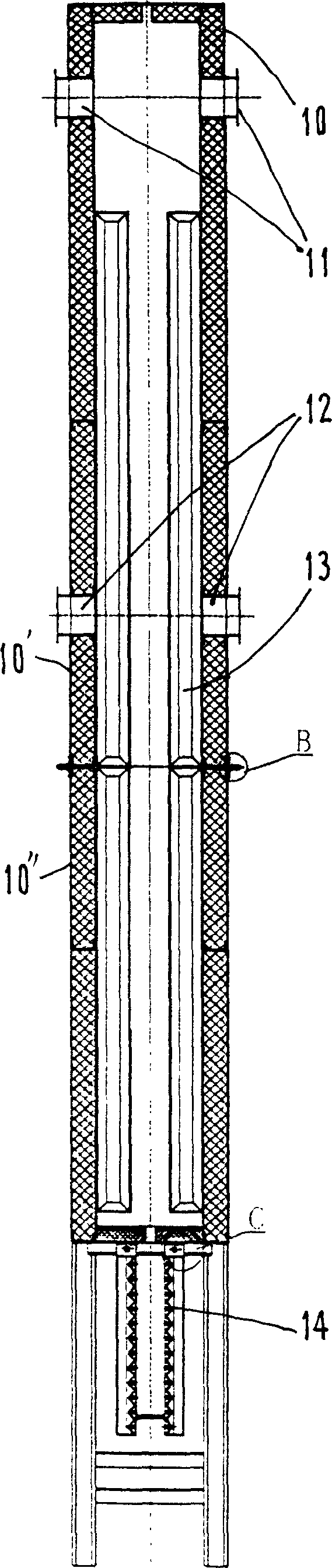

[0020] refer to figure 1 , 2. The conveyor belt production line includes: a set of plasticizing system, front equipment 5, traction system 7 and control system, etc. The overall belt core 6 is stretched through the front equipment 5 and plasticization system, and is pulled by the traction system 7 Advance; front equipment 5 includes equipment such as vacuum tower 51, drying oven 52 and dipping tank 53; Traction system 7 includes main tractor 71, auxiliary tractor 72 and drying tractor 73, wherein main tractor 71 is arranged on the whole At the output end of the belt core 6, the auxiliary tractor 72 is arranged in the middle of the plasticizing system, and the drying tractor 73 is arranged between the drying box 52 and the dipping tank 53; °Turn, each turning point is evenly equipped with guide rollers to guide the overall belt core with 6 turns; the production line is equipped with a full-process control system to achieve good management and strict quality control.

[0021] T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com