Preparation method for temperature-sensitive medium used for wax temperature control valve

A temperature control valve and temperature-sensitive technology, which is applied in the petroleum industry, hydroprocessing process, and hydrocarbon oil treatment, can solve the problems that the performance cannot meet the requirements of use, and achieve stable product performance, low price, and long service life. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] (1) Using the product of the low-temperature F-T synthesis experimental device of China Petroleum & Chemical Corporation as the raw material, the fraction with a boiling point of 240°C to 360°C was prepared by vacuum distillation in a distillation apparatus with 17 theoretical plates. The weight content of normal paraffins in this cut is 95%, and other components account for about 5%.

[0024] (2) the above-mentioned cuts obtained in the FHJ-2 catalyst (a kind of Ni / Al 2 o 3 Commercial catalyst, developed and produced by Fushun Petrochemical Research Institute, the content of active metal nickel in terms of oxides is 40%, and the catalyst is subjected to conventional reduction treatment before use) under the conditions of 5MPa, 200°C, 1.0LHSV and hydrogen-to-liquid ratio of 800 Hydroconversion is used to convert olefins and oxygen-containing compounds therein, and the weight content of normal paraffins in the hydrogenation product is close to 100%.

[0025] (3) the ab...

Embodiment 2

[0028] (1) with embodiment 1;

[0029] (2) Put the above-mentioned cuts on FV-10 catalyst (a kind of W-Mo-Ni / Al 2 o 3 Type commercial catalyst, developed and produced by Fushun Petrochemical Research Institute, the catalyst is subjected to conventional sulfurization treatment before use) under the action of 6MPa, 280°C, 1.0LHSV and hydrogen-to-liquid ratio of 300 for hydrogenation conversion to convert olefins and oxygen-containing compound, and the weight content of n-alkanes in the hydrogenation product is close to 100%.

[0030] (3) the above-mentioned product obtained through hydrogenation conversion is in a distillation unit with 25 theoretical plates, at 1.33 × 10 3 Under Pa pressure, the distillate at 260-340°C is prepared. This fraction is the target product.

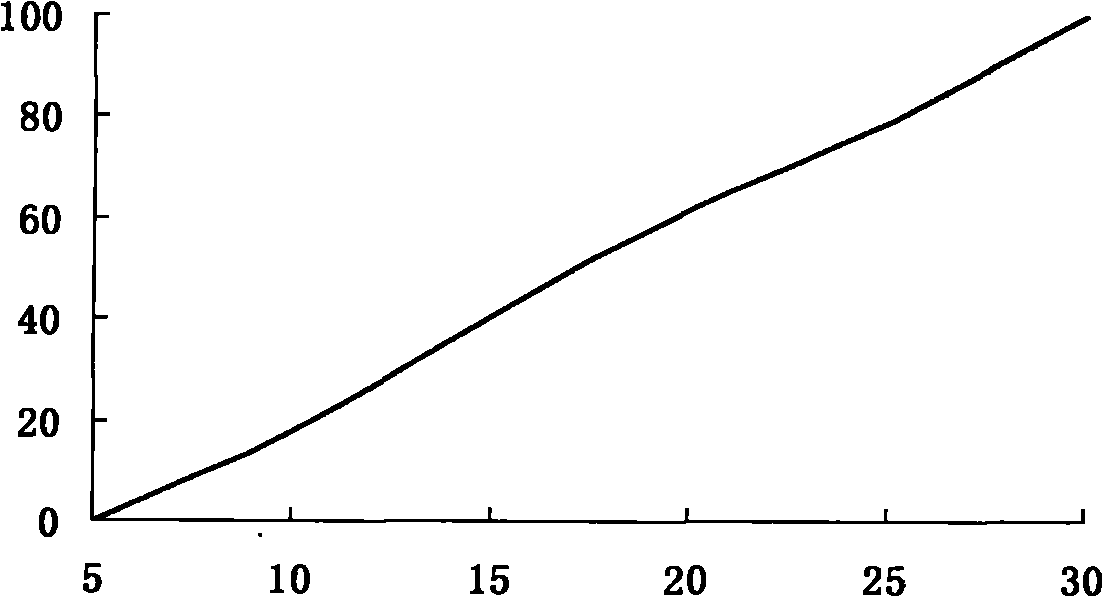

[0031] The expansion performance curve of the heating temperature control valve made of this product is as follows: figure 2 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com