Corrugated pipe with three layers of single walls

A technology of single-wall corrugated pipes and corrugated pipes, applied in the field of three-layer single-wall corrugated pipes, to achieve stable product performance and broaden the application field

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Below in conjunction with the embodiment shown in the accompanying drawings, the present invention is described in detail as follows:

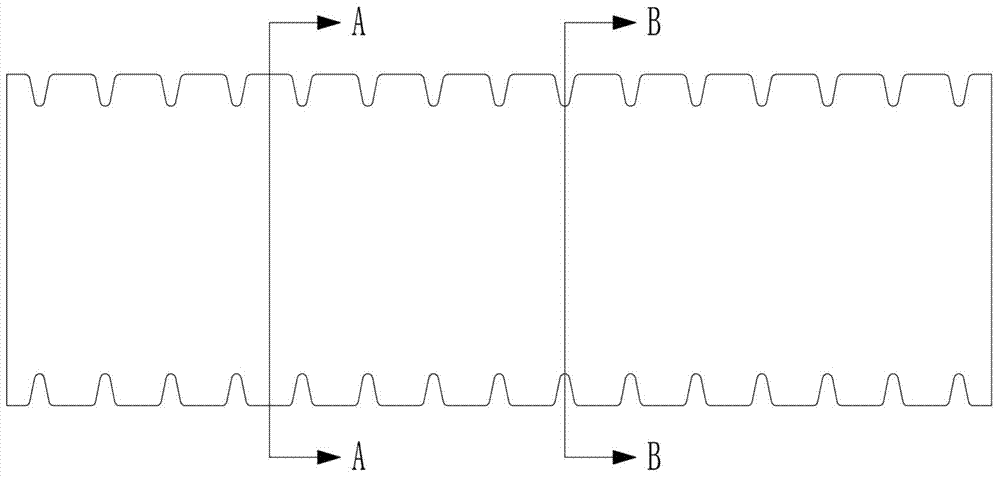

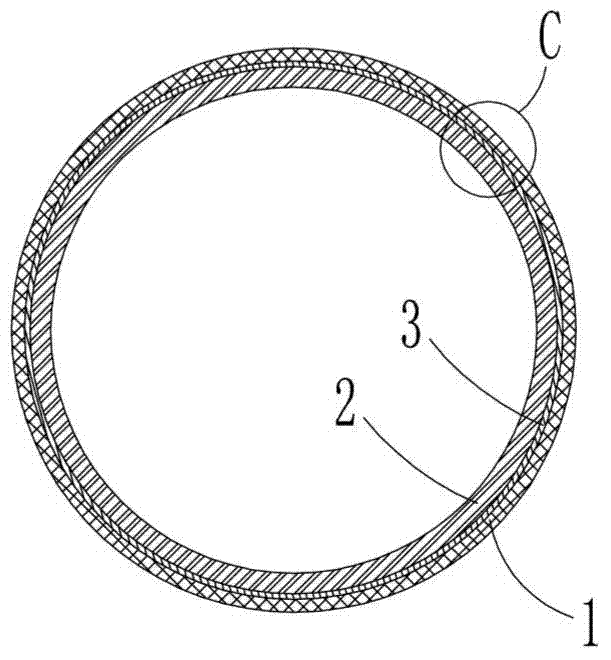

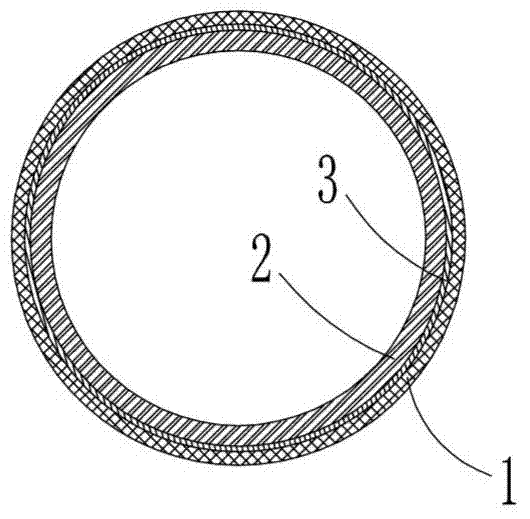

[0017] as attached figure 1 To attach Figure 4 As shown, a three-layer single-wall corrugated pipe has a single-wall body, and the wall body includes an outer layer 1, an inner layer 2, and a cementing layer that fixes the outer layer 1 and the inner layer 2 together. 3. The thickness of the inner layer 2 is greater than the thickness of the outer layer 1, the thickness of the outer layer 1 is greater than the thickness of the cementing layer 3, and the thickness of the inner layer 2 accounts for the total wall body One-third to two-thirds of the thickness, the thickness of the cement layer 3 is 0.1-0.5 mm, and the outer layer 1 and the outer layer 1 use different raw materials.

[0018] The outer layer 1 and inner layer 2 of the three-layer single-wall corrugated pipe in this design choose different raw materials according to differ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com