Industrially-synthesized magnesium-iron-aluminum compound spinel and synthetic method thereof

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

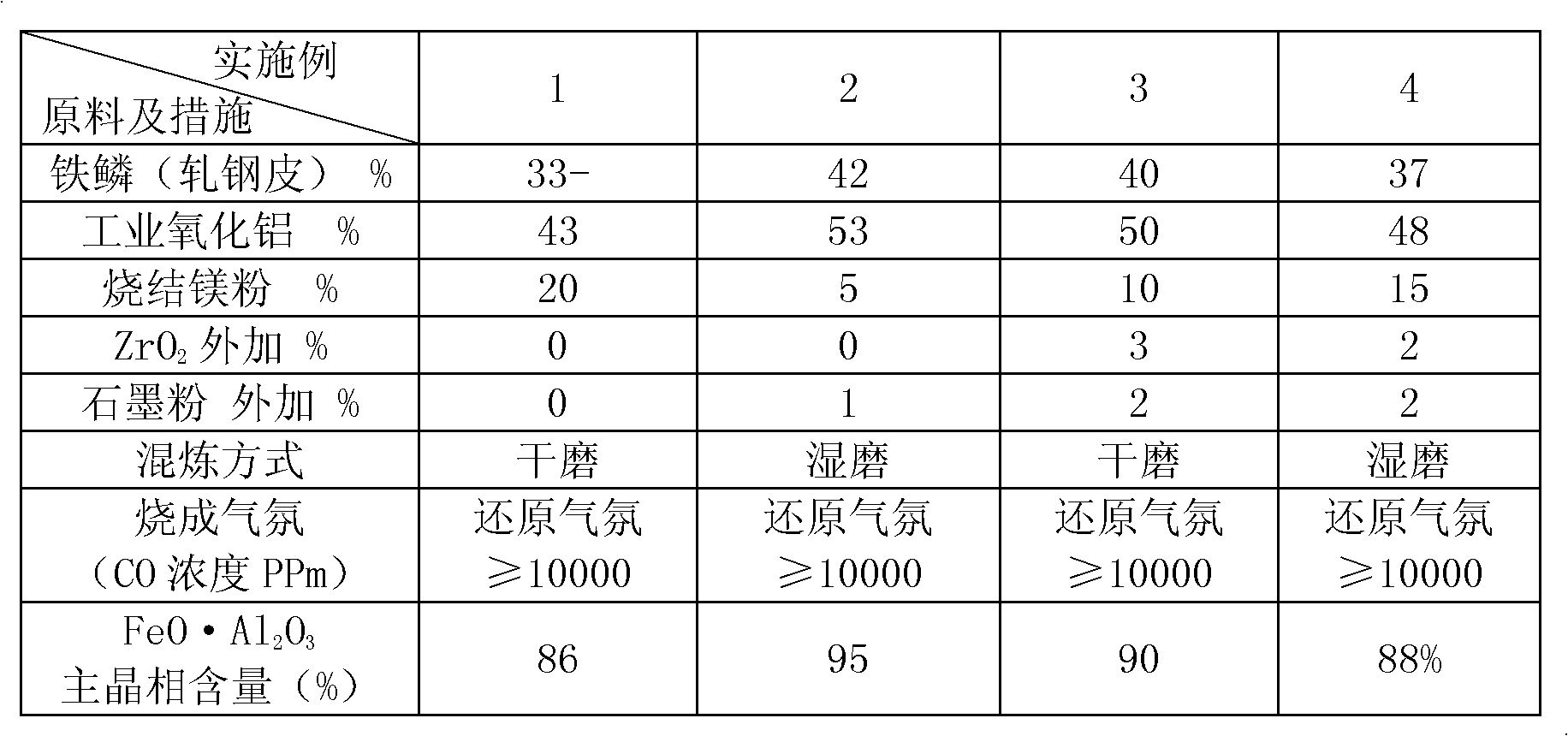

Examples

Embodiment

[0026] The ingredients are iron compounds, industrial alumina, magnesium-containing compounds, carbon-containing compounds, zirconium-containing oxides and binders. All raw materials are passed through a 80-mesh sieve, and the ingredients meet the chemical composition requirements of the product: Fe 2 o 3 25-45%, Al 2 o 3 35~55%, MgO0~30%, ZrO 2 0~5%. The binding agent is one of pulp waste liquid, starch, dextrin, resin, polyvinyl alcohol and methyl cellulose, which were tested respectively, and the addition amount is 1 to 6% of the total weight of the ingredients, and 3%, 4 %, 4.5% and 6% were tested.

[0027] The ingredients can be ground and pulverized, either dry or wet, and can be pressed on a 400-1200-ton press to make a billet, or mixed with an appropriate amount of water, then vacuumed and squeezed to make a billet, and dried at 110°C.

[0028] For industrial kilns, the temperature rises naturally before 600°C; the heating process of 600-1200°C turns into a red...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com