Dyeing polyurethane resin and application of dyeing polyurethane resin in synthetic leather

A technology of polyurethane resin and synthetic leather, which is applied in the direction of textiles and papermaking, etc., to achieve stable product performance, good antibacterial effect, and good fastness to wet treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

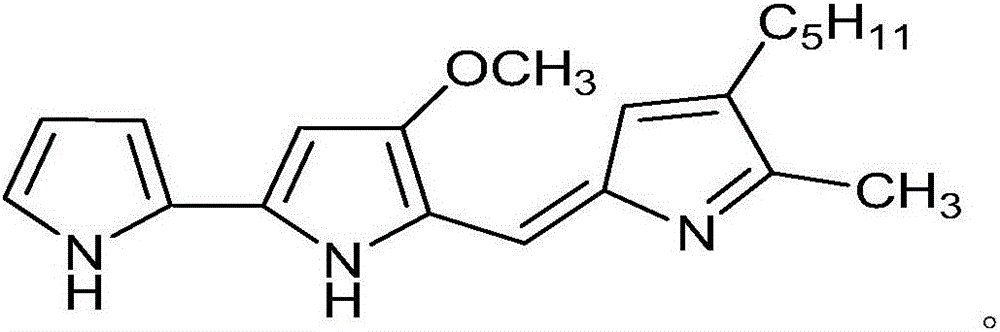

Image

Examples

Embodiment 1

[0045] Get each raw material of following parts by weight respectively:

[0046]

[0047] Utilize the raw material of above-mentioned weight part to prepare printing paste, comprise the following steps:

[0048] (1) Grind 5 parts of prodigiosin with a ball mill to a fine powder with a particle size between 0.5 and 2 μm, add the fine powder to 15 parts of DMF (dimethylformamide), mix well, and obtain A liquid;

[0049] (2) PU solution prepared by mixing 20 parts of polyurethane resin with 60 parts of DMF to obtain liquid B;

[0050] (3) Add liquid A to liquid B, mix, beat, and homogenize to keep the pH value at a weakly acidic 6-6.5 to obtain PU color paste.

[0051] (4) Scrape-coat the PU color paste on the base cloth, then enter the wet coagulation bath, and then further wash and dry to obtain the PU leather wet fabric layer.

[0052] (5) Pour the PU color paste onto the polytetrafluoroethylene board by scraping, and then dry it to make a film with a thickness of about ...

Embodiment 2

[0056] Take 0.01 part, 0.5 part, 2 parts, 8 parts, 10 parts of prodigiosin respectively, the parts by weight of other raw materials are the same as in Example 1, and the preparation method of PU color paste is the same as in Example 1. The method of step (5) in Example 1 was used to prepare the PU film material in order to test the application performance of the PU color paste, and the specific results are shown in Table 1.

[0057] Table 1 Effect of prodigiosin content on the color effect of PU leather

[0058]

[0059] It can be seen from Table 1 that when the amount of prodigiosin is 0.01 part, its color is lighter. The amount of prodigiosin has little effect on the mechanical properties of PU leather, and basically maintains the original excellent physical and mechanical properties of PU leather. As the amount of prodigiosin increases, the color depth of PU synthetic leather increases, and the color is also brighter and fuller. When the amount of prodigiosin is more t...

Embodiment 3

[0061] Embodiment 1 adopts dimethylformamide (DMF) as solvent, uses 2-butanone (MEK) and ethanol (EA) respectively as solvent replacement dimethylformamide (DMF) in embodiment 1, all the other are the same as embodiment 1. Utilize the above-mentioned raw materials in parts by weight to prepare PU color paste, and then adopt a conventional finishing treatment process preparation method (step (5) method in Example 1) to prepare a PU finishing layer. The influence of solvent types on the color effect of PU leather is shown in Table 2.

[0062] Table 2 The effect of solvent types on the color effect of PU leather

[0063]

[0064] As can be seen from Table 2, when DMF is used as the solvent, the mechanical properties of the PU material are excellent, the color is bright, the color is full, and the fastness to wet treatment is excellent. Therefore, the present invention selects DMF as the solvent.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com