Medical hydrophilic coating composition as well as preparation method and application thereof

A technology of hydrophilic coatings and hydrophilic polymers, applied in polyurea/polyurethane coatings, coatings, devices for coating liquids on surfaces, etc., can solve the health hazards of operators and increase the production cost of coating liquids , Strict requirements for the use environment, etc., to achieve excellent adhesion, meet the requirements of biological modification and hydrophilicity, and the effect of simple and convenient application process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] The preparation of medical hydrophilic coating composition of the present invention comprises the following steps:

[0028] Raw materials are prepared according to the following percentages by weight (wt%): 0.1-2 parts (wt%) of hydrophilic polyurethane, 0.1-1 part (wt%) of hydrophilic polymer, 47-90 parts (wt%) of ethanol, the remainder The amount is water.

[0029] Take hydrophilic polyurethane and ethanol and mix according to the weight volume ratio of 0.2-4:100, heat and stir to dissolve, and obtain hydrophilic polyurethane ethanol solution for later use.

[0030] The hydrophilic polymer and water are mixed according to the weight volume ratio of 0.2-2:100, heated and stirred to dissolve, and the hydrophilic polymer aqueous solution is obtained for use.

[0031] The above-mentioned hydrophilic polyurethane ethanol solution and the above-mentioned hydrophilic polymer aqueous solution are mixed according to the ratio of 1-9:1, stirred and mixed evenly, and the medical...

Embodiment 2

[0037] The preparation of a microfluidic chip with a hydrophilic coating comprises the following steps:

[0038] Take 4 microfluidic chips, soak the 4 microfluidic chips in the medical hydrophilic coating composition solution described in the above experimental example 1-4 for 30-60s, take out after soaking and dry naturally for 5-10min, and then Bake the microfluidic chip in a constant temperature drying oven at 50-60°C for 1-2 hours to obtain a microfluidic chip with a hydrophilic coating, which is recorded as the microfluidic chip coated with a hydrophilic coating experiment. Groups 1-4.

[0039] In the present invention, a control group of microfluidic chips is additionally set, and the chip of the control group is a chip not coated with a hydrophilic coating.

Embodiment 3

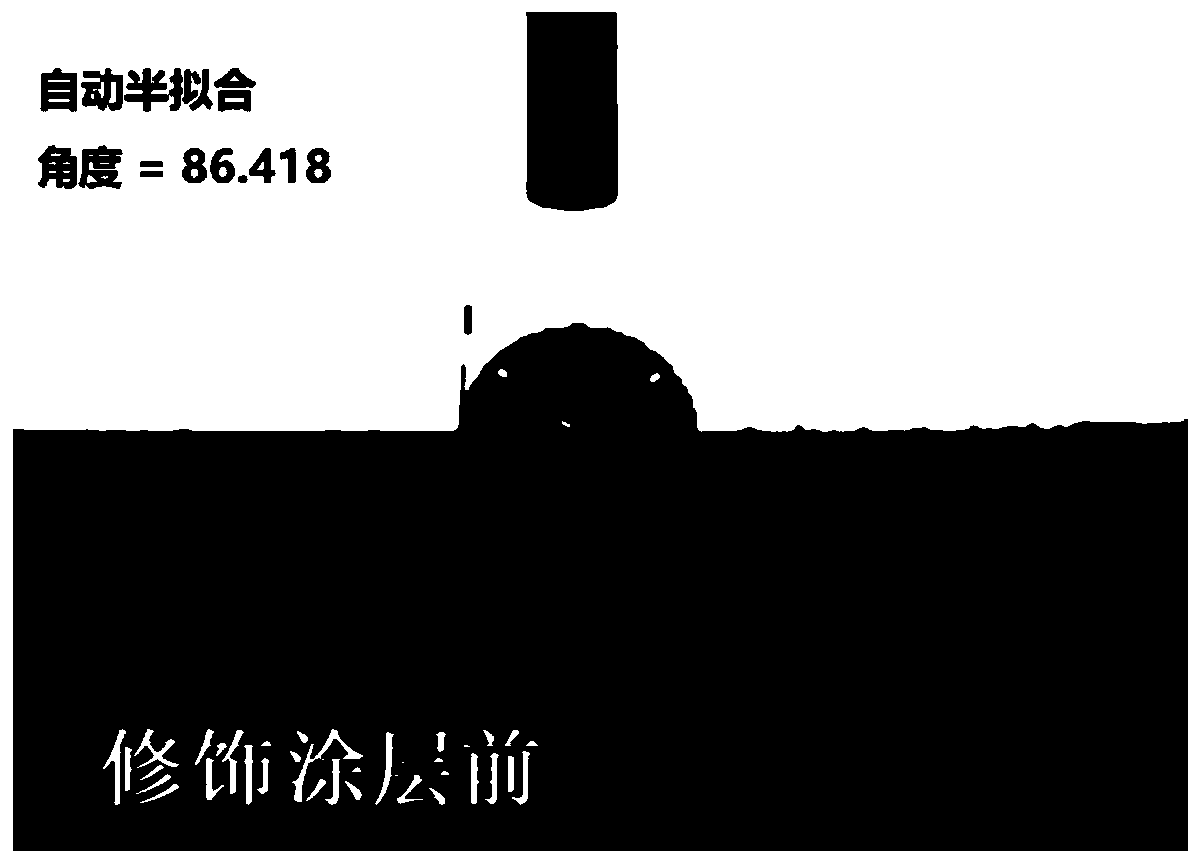

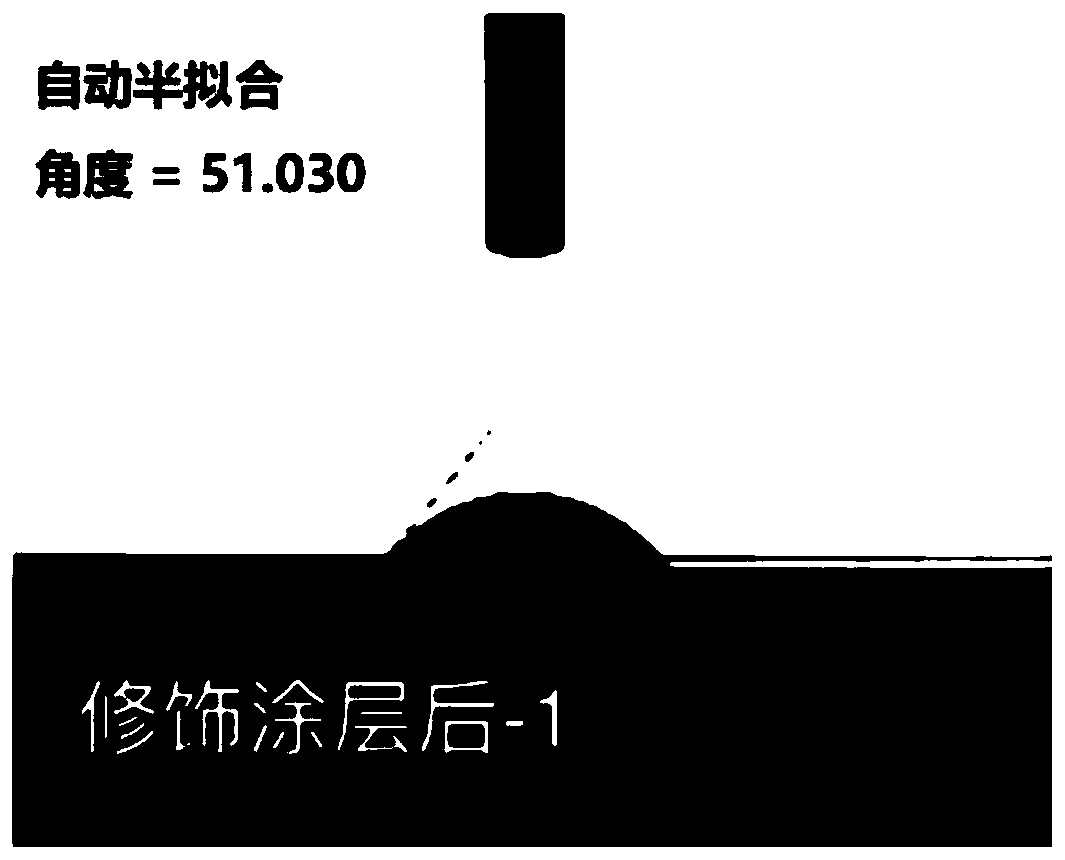

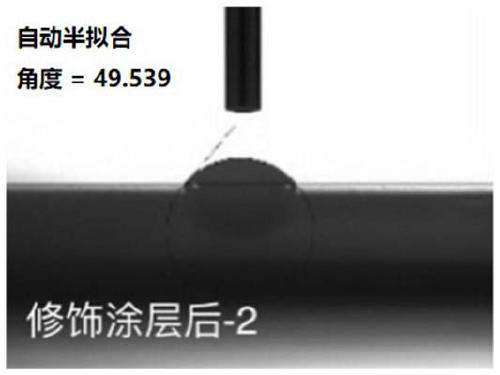

[0041] Hydrophilicity testing of microfluidic chips with hydrophilic coatings. The contact angles of the surfaces of the microfluidic chip experimental groups 1-4 and the control group were tested respectively. figure 1 Shown is the microfluidic chip surface contact angle test chart of the control group. Figure 2 to Figure 5 The test diagrams of the surface contact angles of the microfluidic chip of the experimental examples 1-4 of the present invention are respectively shown.

[0042] Depend on Figure 1 to Figure 5 The shown microfluidic chip is coated with a hydrophilic coating before and after the comparison of the contact angle of the substrate surface. It can be clearly seen that the contact angle of the substrate surface can be changed from about 86 ° is reduced to about 46°, indicating that the hydrophilicity of the microfluidic chip is significantly enhanced after being coated with the hydrophilic coating composition of the present invention. Figure 6 Shown is a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com