Iron-chromium-aluminum cold-rolled coil continuous line annealing and pickling production method

A production method, iron-chromium-aluminum technology, is applied in the production of continuous line annealing and pickling of 1Cr13Al4 iron-chromium-aluminum alloy cold-rolled steel coils, and in the field of continuous-line annealing and pickling of wide-width iron-chromium-aluminum cold-rolled coils, which can solve the problems that cannot be pickled by pickling. Cleaning and other issues to achieve stable product performance and reduce production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0066] The cold-rolled 1Cr13Al4 coil with a thickness of 1.0mm, a width of 1240mm, and a coil weight of 14 tons is used as a raw material. The coil is rolled by a 3.5mm-thick hot-rolled coil through a 20-roller Sendzimir rolling mill. The chemical composition is calculated by mass percentage. For: C: 0.0143%, Cr: 13.8%, Al: 5.2922%, Si: 0.1787%, Mn: 0.0759%, P: 0.0114%, S: 0.001%, Ti: 0.3174%, N: 0.0024%, and the rest is Fe and other unavoidable impurities.

[0067] The production method of the present embodiment is as follows:

[0068] (1) After uncoiling the cold-rolled 1Cr13Al4 steel coil, first cut off the unrolled part and the cold-rolled transition part with the actual thickness of the head ≥ 1.0mm, so as to ensure that there is no parking of the rolling mill on the part with the actual thickness of the steel coil ≥ 1.0mm Roll printing, the unrolled part and the transition part are rolled into a small roll and packed;

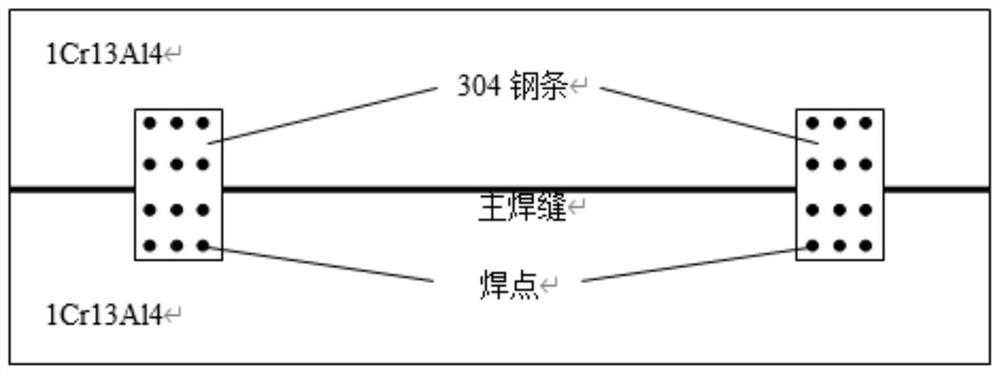

[0069] Send the clean-cut steel coil head to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com