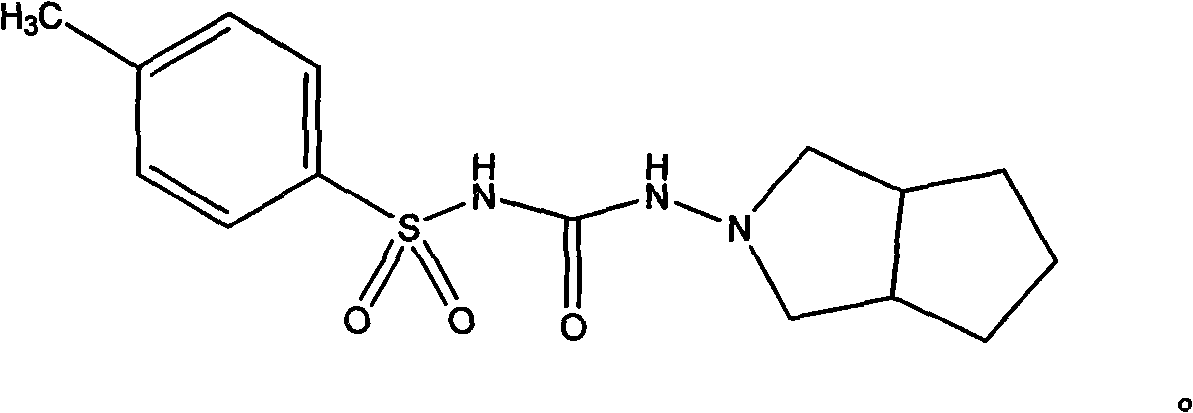

Gliclazide sustained-release capsule and preparation process thereof

A technology of gliclazide and sustained-release capsules, applied in the field of medicine, can solve the problems of many components and complexities, and achieve the effects of less toxic and side effects, high qualification rate and stable product performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] 1. ① Gliclazide pellets prescription:

[0044] Gliclazide 30g

[0045] Microcrystalline Cellulose 30g

[0046] Lactose 60g

[0047] water 30g

[0048] Makes 1000 capsules

[0049] ② Preparation of sustained-release film coating solution:

[0050] Take 5g of EudragitRS100, 30g of EudragitRL100 and 30g of talcum powder and dissolve them in 1000ml of ethanol solution with a volume concentration of 95%, shake well and set aside.

[0051] Second, the preparation process:

[0052] (1) Gliclazide is pulverized to 100 mesh;

[0053] (2) Take 30g of 100-mesh gliclazide, 30g of microcrystalline cellulose, and 60g of lactose and mix evenly, add 30g of water as a wetting agent to make a soft material, and put it into an extrusion rolling pellet machine at a speed of 400 rpm Granulate and dry at 80°C for 4 hours to obtain gliclazide pellets;

[0054] (3) Select 20-mesh gliclazide pellets and put them into the coating machine, adjust the speed of the coating machine to 150 rpm...

Embodiment 2

[0059] 1. ① Gliclazide pellets prescription:

[0060] Gliclazide 30g

[0061] Microcrystalline Cellulose 35g

[0062] Lactose 55g

[0063] water 66g

[0064] Makes 1000 capsules

[0065] ② Preparation of sustained-release film coating solution:

[0066] Take 5g of EudragitRS100, 15g of EudragitRL100 and 10g of talcum powder and dissolve them in 1000ml of ethanol solution with a volume concentration of 95%, shake well and set aside.

[0067] Second, the preparation process:

[0068] (1) Crush gliclazide to 80-100 mesh;

[0069] (2) Take 30g of 80-100 mesh gliclazide, 35g of microcrystalline cellulose, and 55g of lactose, mix evenly, add 66g of water as a wetting agent to make a soft material, put it into an extrusion rolling pellet machine at 800 rpm Gliclazide pellets were obtained by granulating at a rotating speed of 100°C, and then setting the extrusion rolling machine at 40°C, and drying for 10 hours under this condition;

[0070] (3) Select 20-50 mesh gliclazide...

Embodiment 3

[0075] 1. ① Gliclazide pellets prescription:

[0076] Gliclazide 33g

[0077] Microcrystalline Cellulose 50g

[0078] Lactose 45g

[0079] water 70g

[0080] Makes 1000 capsules

[0081] ② Preparation of sustained-release film coating solution:

[0082] Take 20g of EudragitRS100, 40g of EudragitRL100 and 10g of talcum powder and dissolve them in 1000ml of ethanol solution with a volume concentration of 95%, shake well and set aside.

[0083] Second, the preparation process:

[0084] (1) Gliclazide is pulverized to 90 mesh;

[0085] (2) Take 33g of 90-mesh gliclazide, 50g of microcrystalline cellulose, and 45g of lactose and mix evenly, add 70g of water as a wetting agent to make a soft material, and put it into an extrusion rolling pellet machine at a speed of 1000 rpm Granulate, take out and dry in cold air for 10 hours in a sterile environment at 20°C to prepare gliclazide pellets;

[0086] (3) Select 20-40 mesh gliclazide pellets and put them into the coating mach...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com