Preparation method of emulsion-polymerized styrene butadiene rubber

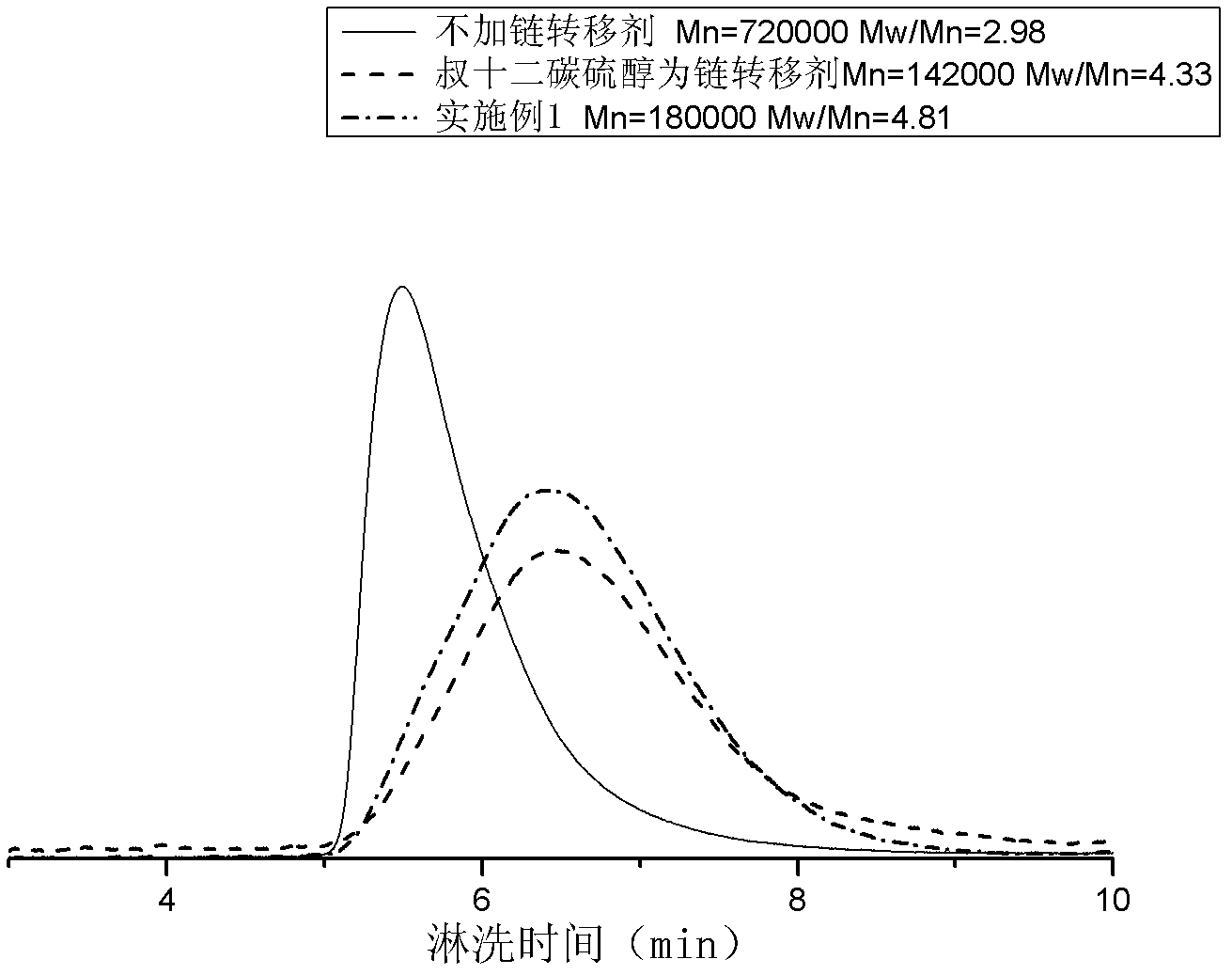

An emulsion polystyrene butadiene rubber, selected technology, applied in the field of preparation of emulsion polystyrene butadiene rubber, can solve the problems of fast consumption of mercaptan, molecular weight control, wide molecular weight distribution, etc., to achieve stable product performance, good molecular weight adjustment effect, good reproducibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] The first is the preparation of the water phase. First, 190g of water, 4.62g of disproportionated abietic acid soap, 0.231g of phosphoric acid, 0.396g of potassium hydroxide, 0.055g of tetrasodium ethylenediaminetetraacetic acid, and 0.13g of sodium dinaphthyl methane disulfonate are sequentially prepared. g, 0.04g of sodium dithionite, 0.01g of ferrous sulfate, and 0.04g of sodium formaldehyde sulfoxylate were added to the reaction flask and stirred evenly.

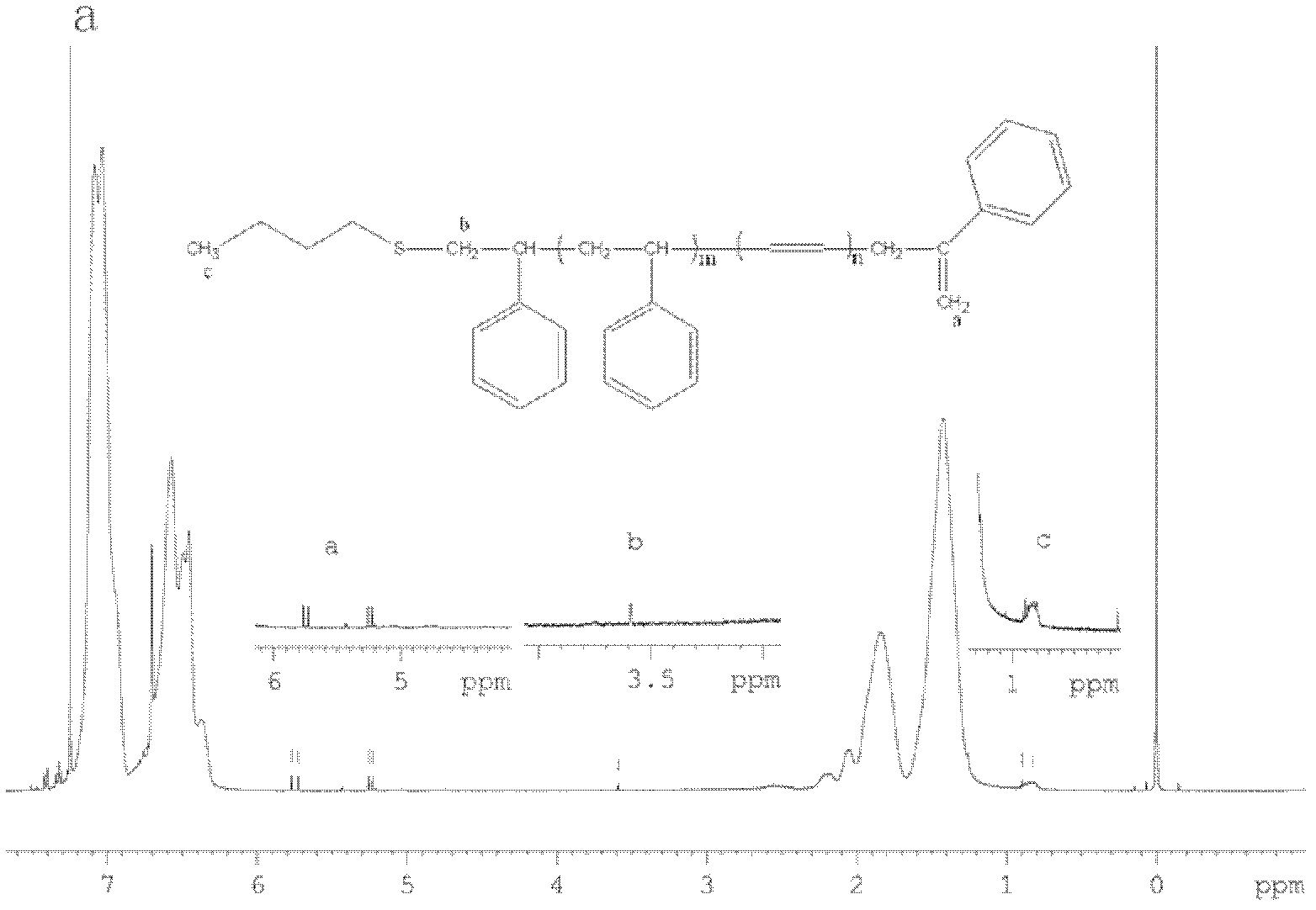

[0045] Next is oil phase preparation, the n-butyl-2-phenyl allyl sulfide of styrene 23g monomer dissolving 0.1g ( figure 2 ), and added to the reaction flask after dissolving evenly. Thereafter, 72 g of butadiene was added, the temperature was lowered to 5° C., and emulsification was performed for 20 minutes.

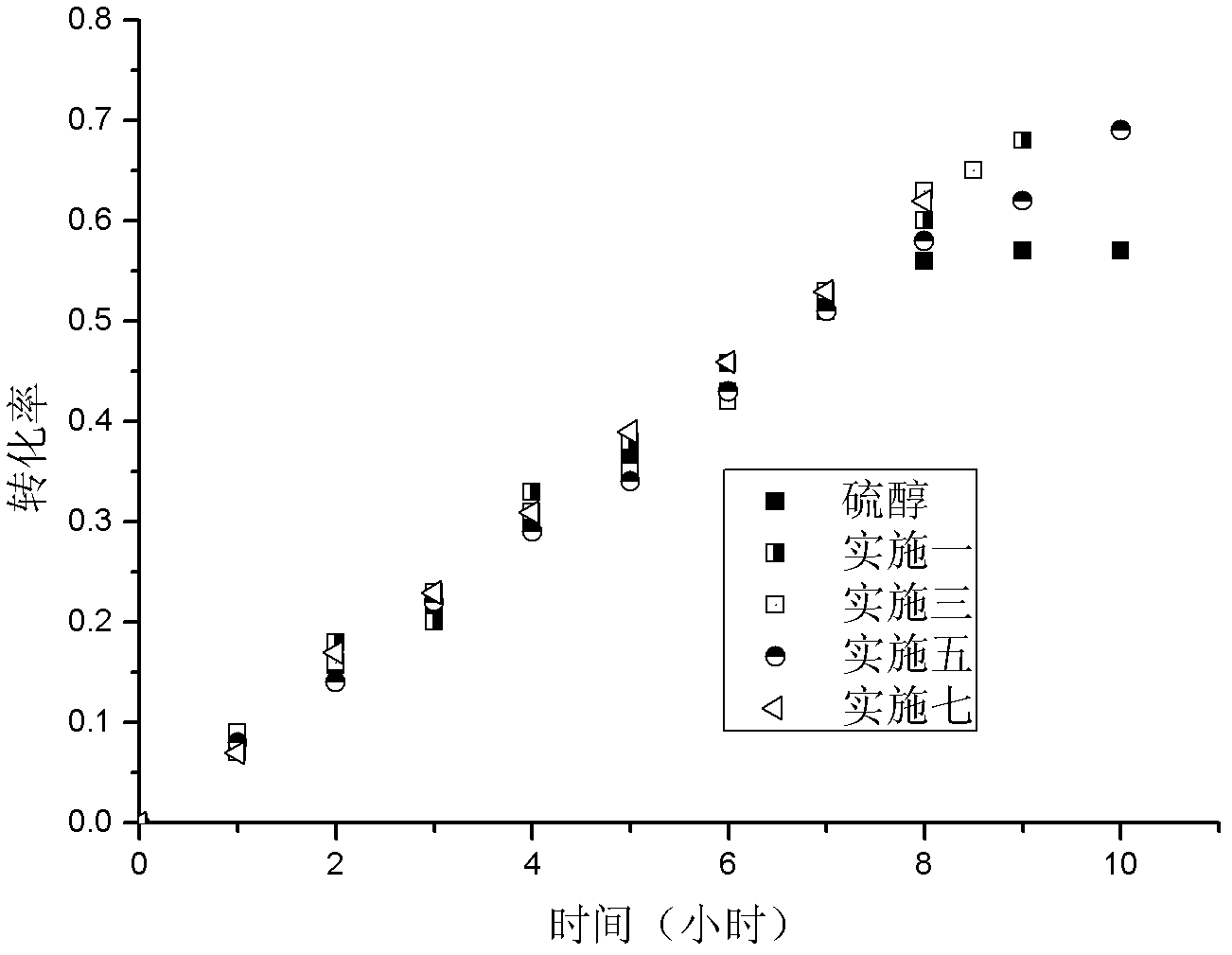

[0046] Finally add oxidizing agent organic solution and comprise 5g styrene, 0.06g hydroperoxide p-menthane, react at 5 ℃ for 9 hours, add terminator solution when conversion rate reaches 68%, wherein con...

Embodiment 2

[0048] The first is the preparation of the water phase. First, 185g of water, 4.65g of disproportionated abietic acid soap, 0.235g of phosphoric acid, 0.4g of potassium hydroxide, 0.05g of tetrasodium ethylenediaminetetraacetic acid, and 0.15g of sodium dinaphthyl methane disulfonate are successively prepared. g, 0.05 g of sodium dithionite, 0.01 g of ferrous sulfate, and 0.03 g of sodium formaldehyde sulfoxylate were added to the reaction flask and stirred evenly.

[0049] Next is oil phase preparation, the n-butyl-2-phenyl allyl sulfide of styrene 24g monomer dissolving 0.15g ( figure 2 ), and added to the reaction flask after dissolving evenly. Thereafter, 72 g of butadiene was added, and the temperature was lowered to 4° C., and emulsification was performed for 20 minutes.

[0050] Add oxidizing agent organic solution at last and comprise 4g styrene, 0.05g hydrogen peroxide p-menthane, react at 5 ℃ for 10 hours, add terminator solution when conversion rate reaches 70%, w...

Embodiment 3

[0052] The first is the preparation of the water phase, which contains 188g of water, 4.7g of disproportionated abietic acid soap, 0.24g of phosphoric acid, 0.4g of potassium hydroxide, 0.05g of tetrasodium ethylenediaminetetraacetic acid, and 0.15g of sodium dinaphthylmethane disulfonate. g, 0.05 g of sodium dithionite, 0.01 g of ferrous sulfate, and 0.03 g of sodium formaldehyde sulfoxylate were added to the reaction flask and stirred evenly.

[0053] Next is oil phase preparation, the n-dodecyl-2-phenyl allyl sulfide of styrene 23g monomer dissolving 0.1g ( figure 2 ), and added to the reaction flask after dissolving evenly. Thereafter, 72 g of butadiene was added, the temperature was lowered to 6° C., and emulsification was performed for 15 minutes.

[0054] Add oxidizing agent organic solution at last and comprise 5g styrene, 0.06g hydroperoxide p-menthane, react at 6 ℃ for 8.5 hours, add terminator solution when conversion rate reaches 65%, wherein contain dithiocarbam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com