Method for producing printed circuit board

A technology of printed circuit boards and production methods, applied in the direction of multi-layer circuit manufacturing, etc., to achieve the effects of stable product performance, weight reduction, and reliable connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

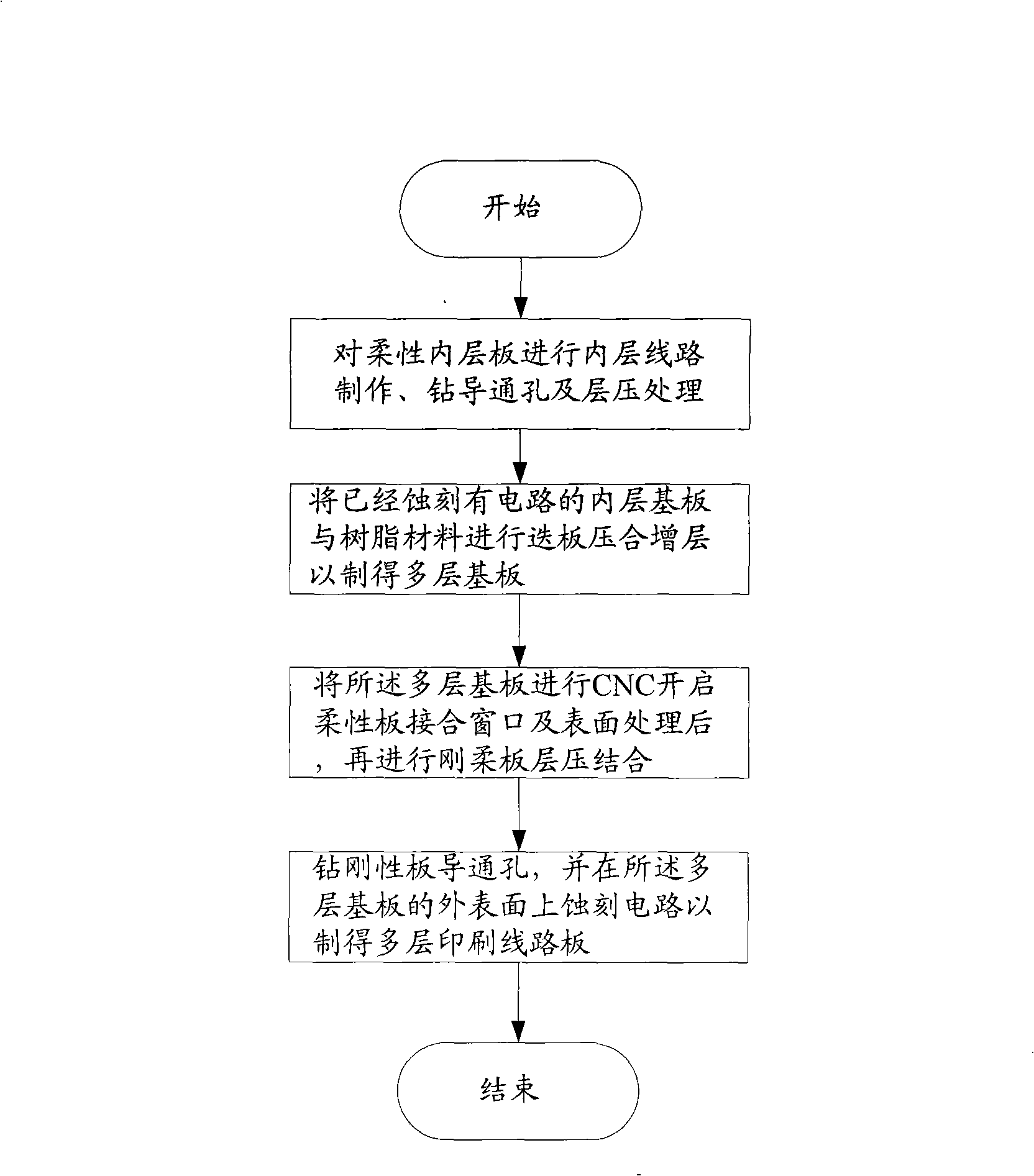

[0022] The core idea of the present invention: By adopting the copper glue through-hole method and the process sequence of "etching the circuit first, then drilling the through-hole", the product performance is more stable, and it is more suitable for the large-scale production and manufacture of multi-layer printed circuit boards.

[0023] In order to facilitate a further understanding of the present invention, the present invention will now be described in detail in conjunction with the accompanying drawings and specific embodiments.

[0024] see figure 1 As shown: the production process or main steps of the multi-layer printed circuit board used in the present invention are: firstly, the flexible board is made partly-cutting the material according to the required size, and then the inner layer circuit is made and carried out according to the drawing. Blackening treatment, and then pressing treatment, after the completion of the above, drill via holes according to the requ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com