Glass fiber humidity conditioning device

A glass fiber and humidity control technology, applied in the direction of coating, etc., can solve the problems of long glass fiber dispersion and shear instability, glass fiber moisture instability, and product color changes, and achieve stable production progress, efficiency, and stability Color and luster, easy to adjust and effective effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

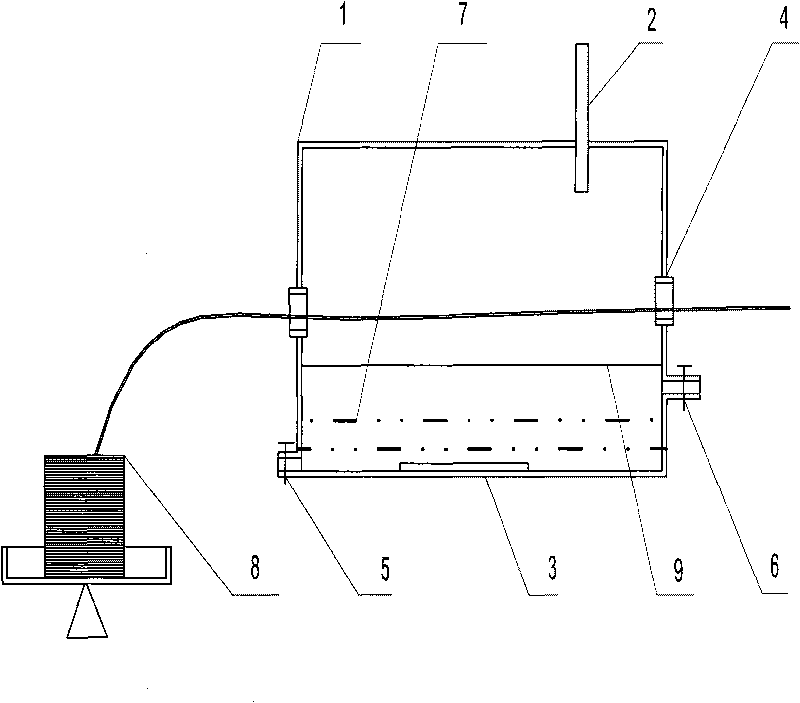

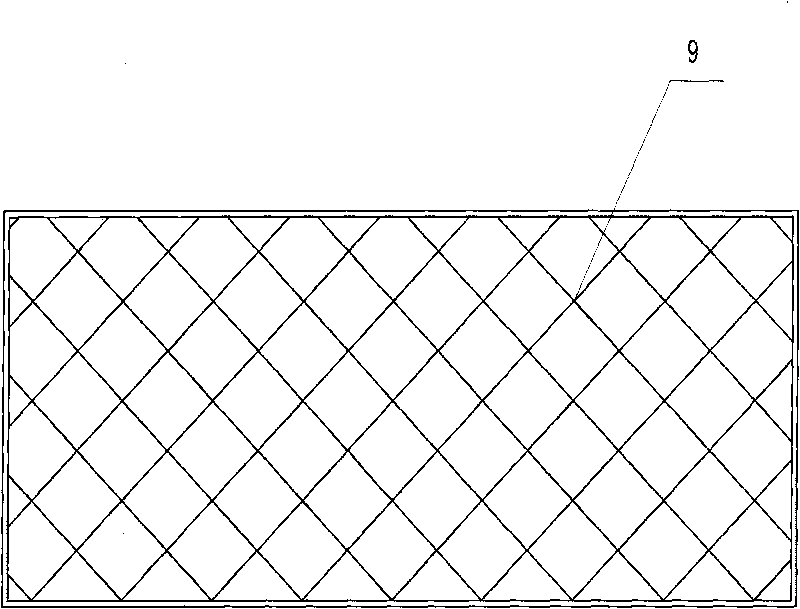

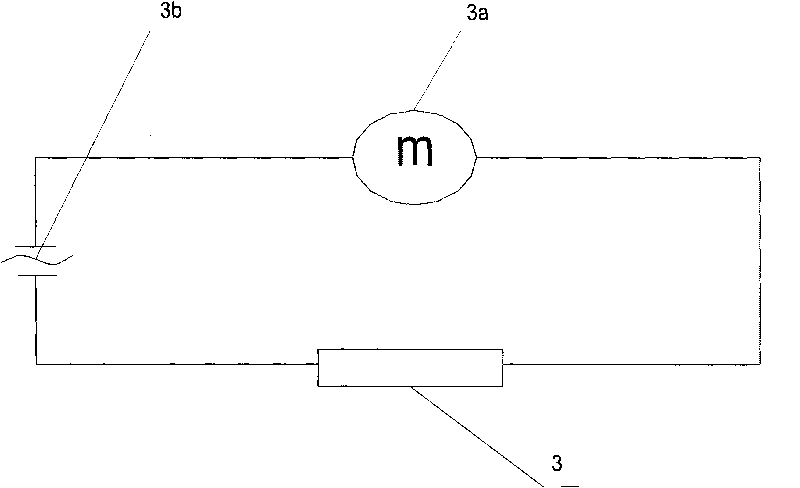

[0027] A device for adjusting the water content of long glass fibers, including a water tank 1 and a heater 3. The long glass fibers 8 pass through the through holes 4 on both sides of the water tank 1. After being heated by the heater 3, water vapor is generated inside the tank body 1. The glass fiber 8 changes its own water content in the environment of water vapor. The air humidity in the box 1 is measured by the hygrometer 2. The water content of the long glass fiber 8 can be changed by changing the humidity in the special water tank 1. In the box 1 The air humidity can be achieved by adjusting the frequency converter 3a in the heater 3 to change the heating power. When the water in the tank 1 is not enough, you can open the valve on the water inlet 6 to supplement the normal temperature water. The water frequency is very low, so it can be done by manually adjusting the valve.

Embodiment 2

[0029] When the air humidity in the box body 1 is not suitable, the production amount of water vapor can also be changed by changing the flow rate of the water inlet 6 and the drain port 5, so as to change the air humidity in the box body 1 and change the content of the long glass fiber 8. water volume.

Embodiment 3

[0031] When the speed of the long glass fibers 8 passing through the box 1 is changed, the purpose of changing the air humidity in the box 1 as in Example 1 or Example 2 can also be achieved, so that the water content of the long glass fibers 8 meets the production requirements. If in some occasions, the speed of the glass fiber 8 passing through the casing 1 does not match the speed of producing modified plastic particles, it should not be used.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com