Nano composite water absorbing material, and preparation method

A water-absorbing material and nano-composite technology, which is applied in the field of nano-composite water-absorbing materials and preparation, can solve the problem that it is difficult to completely eliminate the interfacial tension between filler and polymer matrix, the mineral powder cannot reach the molecular dispersion level, and the enhancement effect and heat resistance are affected. problem, to achieve the effect of easy implementation of post-processing technology, low production cost and less equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

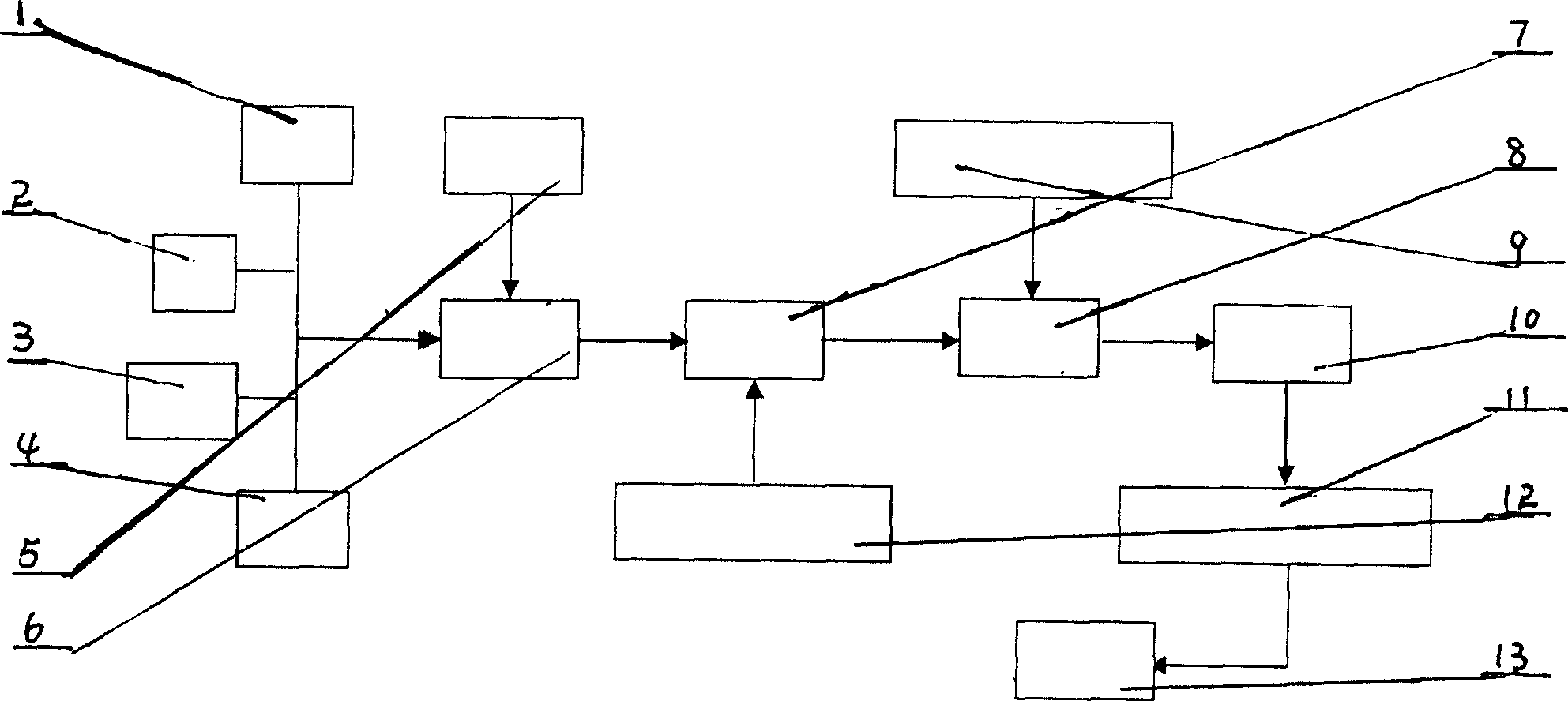

Image

Examples

example 1~4

[0020] Add 15 grams of acrylamide and 5 grams of acrylic acid to a beaker filled with deionized water. After the acrylamide is dissolved, slowly add sodium carbonate to neutralize the acrylic acid in the solution, adjust the pH to 7, and then add 5 grams of starch in turn. and 0.00015 grams of N, N-methylenebisacrylamide, heated up to 75 ° C, stirred evenly, so that the starch gelatinized in the monomer solution, and when the solution changed from turbid milky white to colorless, the total mass was maintained at 100 In the case of gram, add 2 grams, 5 grams, 8 grams and 10 grams of modified montmorillonite respectively, continue to stir, take it out from the three-necked beaker and put it in the beaker after about 25 minutes, cool down to 60 ° C, add 0.25 grams of over Ammonium sulfate initiator, after gelation for a certain period of time, the gel block product can be obtained after standing at room temperature for 1 hour. Finally, the composite material gel particles are pre...

example 3

[0022] The water absorption of the sample in Example 3 in solutions of different concentrations of NaCl is shown in Table 2; the water absorption in several salt solutions with a concentration of 0.5% is shown in Table 3.

[0023] NaCl content, %

[0024] Salt (concentration 0.5%)

[0025] The data in Table 2 and Table 3 show that as the concentration of the external salt solution increases and the valence of salt ions increases, the water absorption rate of the composite water-absorbing agent decreases significantly. The data in Table 3 also shows that the nano-composite water-absorbing ingredients have particularly good water-absorbing properties for ammonium salts, potassium salts, and artificial urine, which shows that they have a strong ability to retain water and fertilizer.

example 5~8

[0027] Add 17 grams of acrylamide and 3 grams of acrylic acid into a beaker filled with deionized water. After the acrylamide is dissolved, slowly add sodium carbonate to neutralize the acrylic acid in the solution, adjust the pH to 7, and then add 6 grams of starch and 0.00015 grams of N, N-methylenebisacrylamide, heated up to 75 ° C, stirred evenly, so that the starch is gelatinized in the monomer solution, and when the solution turns from turbid milky white to colorless, keep the total mass at 100 grams 2 grams, 5 grams, 8 grams and 10 grams of modified montmorillonite were added respectively, and the stirring was continued. After about 25 minutes, it was taken out from the three-necked beaker and put into a beaker. The temperature was lowered to 60°C, and 0.25 grams of over Ammonium sulfate initiator, after gelation for a certain period of time, the gel block product can be obtained after standing at room temperature for 1 hour. Finally, the composite material gel particle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com