Lithium iron phosphate composite positive electrode material with surface coated with titanium nitride and graphene as well as preparation method and application of material

A composite cathode material, lithium iron phosphate technology, applied in the direction of battery electrodes, electrochemical generators, electrical components, etc., can solve the application limitations of graphite anode materials, the improvement of high current charge and discharge performance is not obvious, etc. Electron and ion transport ability, improved high rate capability, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

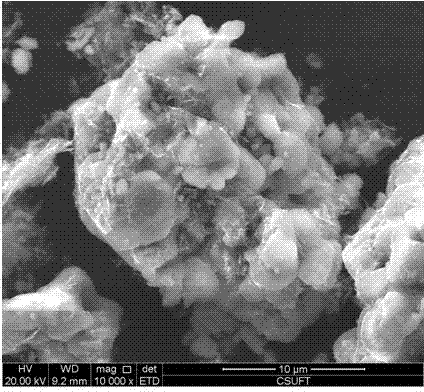

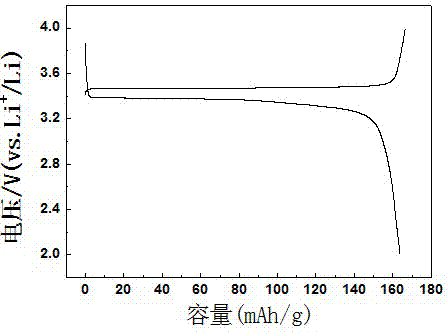

[0027] A lithium iron phosphate composite positive electrode material coated with titanium nitride and graphene on the surface of the present invention, the lithium iron phosphate composite positive electrode material uses lithium iron phosphate material as the core, and a dense layer of lithium iron phosphate material is coated on the surface of the lithium iron phosphate material A conductive network film mainly composed of titanium nitride and graphene; the mass of the conductive network film is 2% of the mass of the lithium iron phosphate material.

[0028] The preparation method of the lithium iron phosphate composite positive electrode material coated with titanium nitride and graphene on the surface of the present embodiment comprises the following steps:

[0029] Add 5g of graphene to 250mL of ethanol, ultrasonic treatment for 1h to form a stable suspension A; dissolve 9.7g of urea and 25.8g of titanium dioxide in 250mL of water to make solution B; put 980g of iron phos...

Embodiment 2

[0033] A lithium iron phosphate composite positive electrode material coated with titanium nitride and graphene on the surface of the present invention, the lithium iron phosphate composite positive electrode material uses lithium iron phosphate material as the core, and a dense layer of lithium iron phosphate material is coated on the surface of the lithium iron phosphate material A conductive network film mainly composed of titanium nitride and graphene; the mass of the conductive network film is 2% of the mass of the lithium iron phosphate material.

[0034] The preparation method of the lithium iron phosphate composite positive electrode material coated with titanium nitride and graphene on the surface of the present embodiment comprises the following steps:

[0035]Add 5g of graphene to 250mL of ethanol, ultrasonic treatment for 1h to form a stable suspension A; dissolve 9.7g of urea and 11.6g of titanium hydroxide in 100mL of organic acid to make solution B; 980 g lithiu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Conductivity | aaaaa | aaaaa |

| Tap density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com