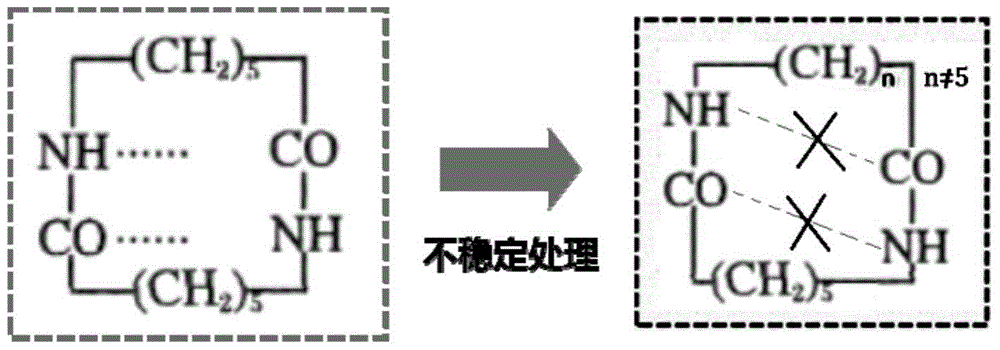

Nylon 6 polymerization method and direct spinning method of melt of polymer obtained with nylon 6 polymerization method

A polymerization method, a technology of direct melt spinning, applied in the direction of conjugated synthetic polymer rayon, melt spinning, textiles and papermaking, etc., can solve the problems of inability to control oligomers, low molecular weight of polymers, and no finding, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

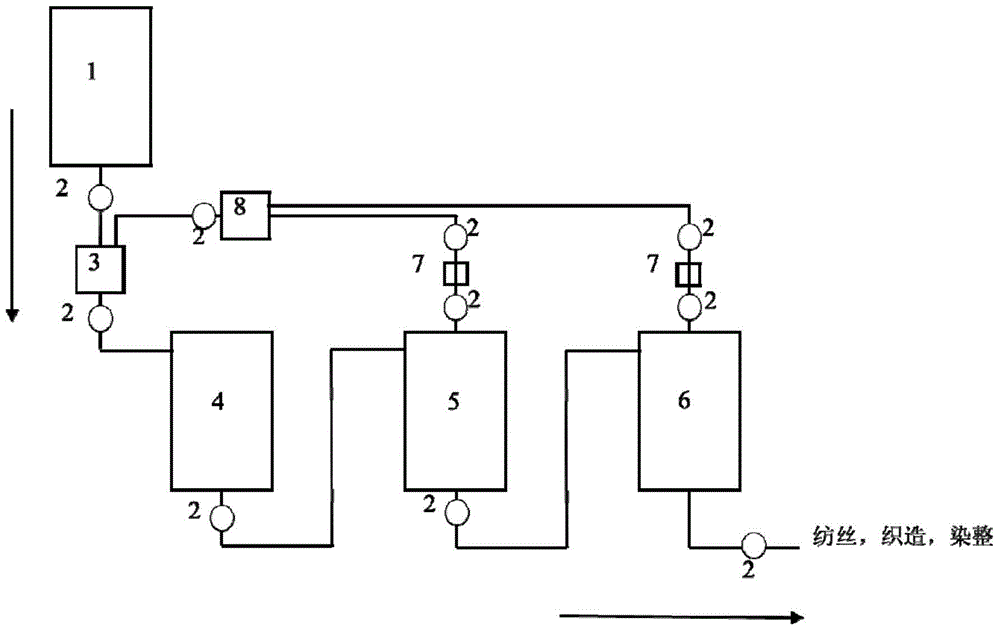

Method used

Image

Examples

Embodiment 1

[0077] Embodiment 1 Nylon 6 polymerization method

[0078] A kind of nylon 6 polymerization method, adopts the method for segmental polymerization to prepare nylon 6, and concrete preparation method is as follows:

[0079] The first stage is the ring-opening reaction stage: at a temperature of 150°C and a pressure of 5 MPa, pre-polymerization is carried out after mixing caprolactam, water and a catalyst. The ring-opening reaction time is 3 hours; the water content is 1wt% of the caprolactam, and the catalyst The content is 20wt% of caprolactam, the catalyst is aliphatic amino acid, and the molecular formula is NH 2 (CH 2 ) x COOH, where x=1;

[0080] The obtained product has a number average molecular weight of 1000, an oligomer content of 30%, a cyclic dimer content of less than 0.1%, and a melt viscosity of 1Pa·s;

[0081] The second stage is the pre-condensation stage: under the conditions of pressure of 10Pa and temperature of 220°C, the product obtained from the ring-...

Embodiment 2

[0085] Embodiment 2 Nylon 6 polymerization method

[0086] A kind of nylon 6 polymerization method, adopts the method for segmental polymerization to prepare nylon 6, and concrete preparation method is as follows:

[0087] The first stage is the ring-opening reaction stage: at a temperature of 220° C. and a pressure of 0.1 MPa, pre-polymerization is carried out after mixing caprolactam, water and a catalyst. The ring-opening reaction time is 12 hours; wherein the water content is 20wt% of caprolactam, Catalyst content is 1wt% of caprolactam, catalyst is aliphatic amino acid, molecular formula is NH 2 (CH 2 ) x COOH, where x=16;

[0088] The obtained product has a number average molecular weight of 1500, an oligomer content of 20%, a cyclic dimer content of less than 0.1%, and a melt viscosity of 5 Pa·s;

[0089] The second stage is the pre-condensation stage: under the conditions of a pressure of 200 Pa and a temperature of 180 ° C, the product obtained from the ring-openi...

Embodiment 3

[0093] Embodiment 3 Nylon 6 polymerization method

[0094] A kind of nylon 6 polymerization method, adopts the method for segmental polymerization to prepare nylon 6, and concrete preparation method is as follows:

[0095] The first stage is the ring-opening reaction stage: at a temperature of 180°C and a pressure of 1 MPa, pre-polymerization is carried out after mixing caprolactam, water and a catalyst. The ring-opening reaction time is 5 hours; the water content is 8wt% of caprolactam, and the catalyst The content is 15wt% of caprolactam, the catalyst is aliphatic amino acid, and the molecular formula is NH 2 (CH 2 ) x COOH, where x=8;

[0096] The obtained product has a number average molecular weight of 2000, an oligomer content of 10%, a cyclic dimer content of less than 0.1%, and a melt viscosity of 100 Pa·s;

[0097] The second stage is the pre-condensation stage: under the conditions of pressure of 100Pa and temperature of 200°C, the product obtained from the ring-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melt viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Melt viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com