Method for polymerizing water-borne acrylate coating

A technology of water-based acrylate and polymerization method, applied in coating and other directions, can solve the problems of complex process, poor emulsion stability, short storage period, etc., and achieve the effect of simplifying polymerization process, improving water resistance, and improving cross-linking degree

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

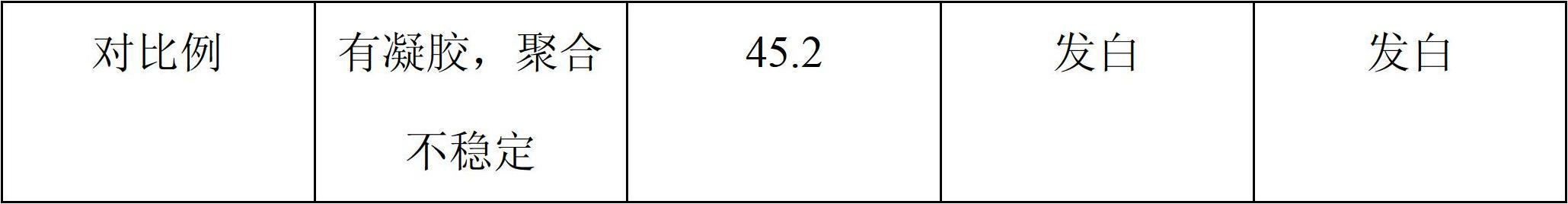

Examples

Embodiment 1

[0034] a) Add the hard monomer dropwise into the emulsifier aqueous solution containing the initiator, and react at 50-90°C; wherein the hard monomer is methyl methacrylate, and the emulsifier is sodium lauryl sulfate, the dosage 0.1wt% of the total mass of the monomer;

[0035] b) After adding the hard monomer dropwise, after the reaction for at least 35 minutes, add the soft monomer dropwise and continue the heat preservation reaction for at least 1 hour; the soft monomer is methyl acrylate; when adding the monomer, add the hard monomer first, and then add the soft monomer Body, so that the latex particles are hard on the inside and soft on the outside, so as to ensure a certain hardness and at the same time form a film at a lower temperature;

[0036] c) adding a metal ion cross-linking agent into the system; after reacting for at least 2 hours, discharging. During the reaction, measure the pH value every 30 minutes, and keep the pH value in the range of 6-8. Wherein, the...

Embodiment 2

[0038] a) Add the hard monomer dropwise into the emulsifier aqueous solution containing the initiator, and react at 50-90°C; wherein the hard monomer is acrylonitrile, and the emulsifier is sodium dodecylbenzenesulfonate, and the dosage is 4wt% of the total mass of the monomer;

[0039] b) After adding the hard monomer dropwise, after the reaction for at least 35 minutes, add the soft monomer dropwise and continue the heat preservation reaction for at least 1 hour; the soft monomer is ethyl acrylate; when adding the monomer, add the hard monomer first, and then add the soft monomer Body, so that the latex particles are hard on the inside and soft on the outside, so as to ensure a certain hardness and at the same time form a film at a lower temperature;

[0040] c) adding a metal ion cross-linking agent into the system; after reacting for at least 2 hours, discharging. During the reaction, measure the pH value every 30 minutes, and keep the pH value in the range of 6-8. Where...

Embodiment 3

[0042] a) Add the hard monomer dropwise into the emulsifier aqueous solution containing the initiator, and react at 50-90°C; wherein the hard monomer is acrylonitrile, and the emulsifier is sodium dodecylbenzenesulfonate, and the dosage is 2wt% of the total mass of the monomer;

[0043] b) After adding the hard monomer dropwise, after the reaction for at least 35 minutes, add the soft monomer dropwise and continue the heat preservation reaction for at least 1 hour; the soft monomer is ethyl acrylate; when adding the monomer, add the hard monomer first, and then add the soft monomer Body, so that the latex particles are hard on the inside and soft on the outside, so as to ensure a certain hardness and at the same time form a film at a lower temperature;

[0044] c) adding a metal ion cross-linking agent into the system; after reacting for at least 2 hours, discharging. During the reaction, measure the pH value every 30 minutes, and keep the pH value in the range of 6-8. Where...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com