Preparation method of propylene random copolymer

A technology of random copolymer and propylene, which is applied in the field of propylene random copolymer and its preparation, which can solve the problem of sticking and agglomerating residual monomers that are difficult to remove cleanly, reduce the melting point and crystallinity of polypropylene resin, and affect product processing and application issues, to achieve the effect of low room temperature xylene soluble content, high relative dispersion, and not easy to stick to the roll

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

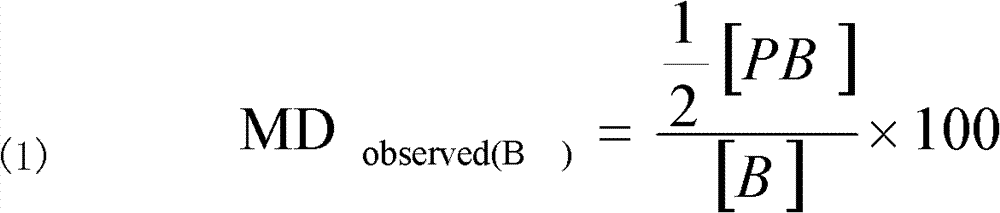

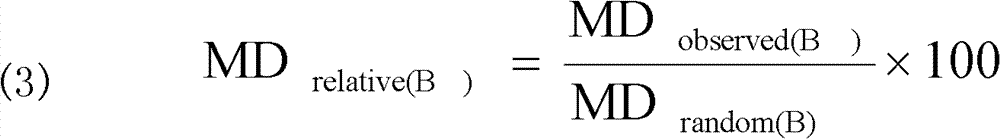

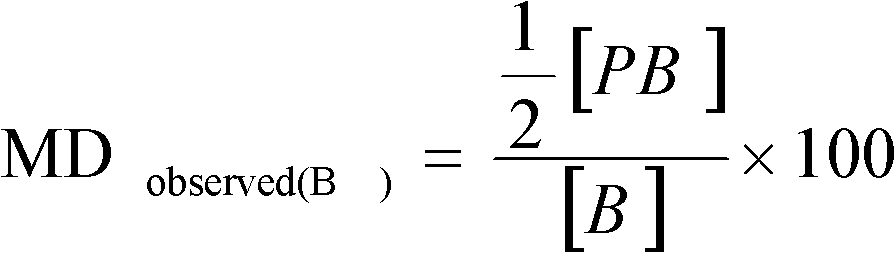

Image

Examples

Embodiment 1

[0063] Polymerization was carried out on a set of pilot plant. Its main equipment includes pre-complexation reactor, pre-polymerization reactor and loop reactor. Polymerization method and steps are as follows:

[0064] (1) Pre-complexation reaction:

[0065] The main catalyst (titanium-containing active solid catalyst component) is obtained by the method described in Example 1 of Chinese Patent CN1258683A, wherein the internal electron donor compound adopts diisobutyl phthalate, and the Ti content of the main catalyst obtained is 1.93wt %, magnesium 19.8wt%, diisobutyl phthalate content 9.3wt%.

[0066] The main catalyst, co-catalyst (triethylaluminum), and external electron donor (methylcyclohexyldimethoxysilane) are respectively added to a jacketed continuous stirring tank through different pipelines for pre-complexation reaction, pre-complexation The temperature is controlled at 8°C by the jacket water, each reaction medium is fed at the bottom and overflowed, and the co...

Embodiment 2

[0075] With embodiment 1, just change catalyst pre-complexation time. The polymerization conditions and polymer properties are shown in Table 1.

Embodiment 3

[0077] With embodiment 1, just change butene-1 addition, H 2 Addition amount and catalyst pre-complexation time. The polymerization conditions and polymer properties are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com