A kind of polyester modified acrylate resin water-based paint and preparation method thereof

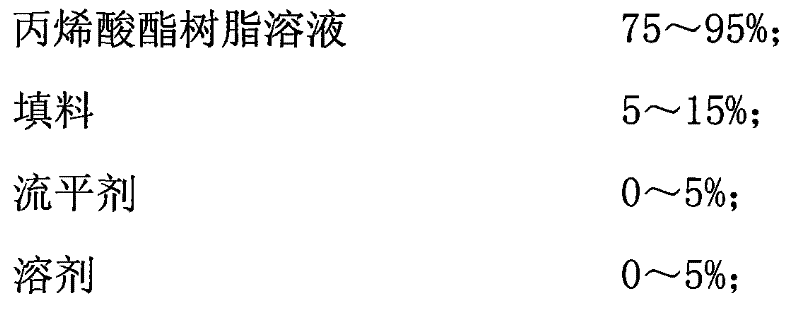

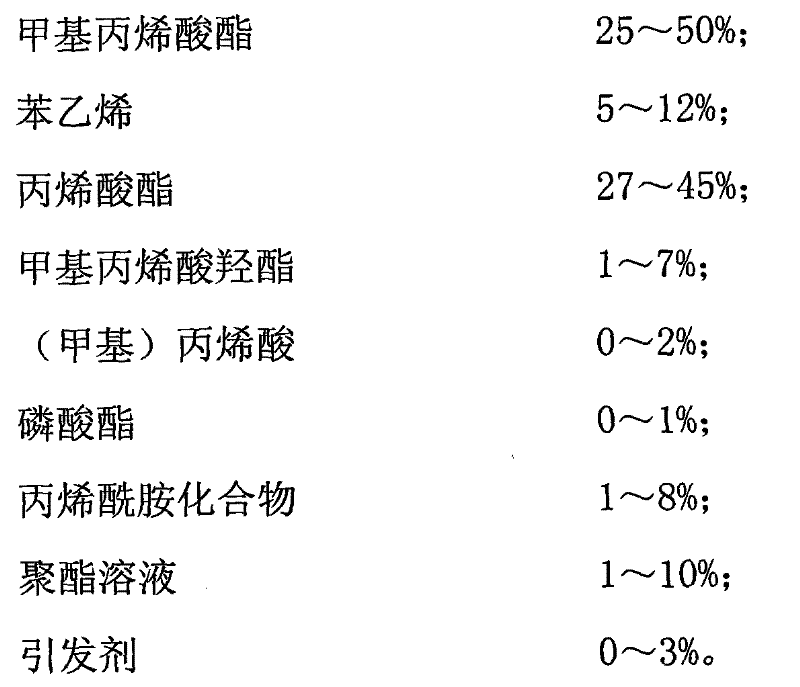

An acrylate and polyester modification technology, used in coatings, devices for coating liquid on surfaces, special surfaces, etc., can solve the problems affecting the appearance quality and appearance, dull gloss, hardness and impact strength of metal components It can achieve the effect of good protection, good solvent resistance and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] A polyester-modified acrylate resin water-based paint, and its formula is composed of 90 grams of acrylate resin solution, 8.5 grams of titanium dioxide, 0.5 grams of Madaaflow, 0.5 grams of methyl ethyl ketone, 9300.3 grams of Emulgen, and 0.2 grams of thickener.

[0038] The preparation method of the polyester-modified acrylate resin water-based paint, take 50 grams of acrylate resin solution, 8.5 grams of titanium dioxide, 0.5 grams of Madaaflow, 0.5 grams of methyl ethyl ketone, mix them evenly and grind them with a ball mill to make the particle size ≤ 10um; take 40 grams The acrylate resin solution was added to the ground mixture, dispersed in 2000 grams of water at 15°C, filtered and washed with water to obtain a filter cake with a solid content of 50%, with an average particle size of 100um; filter 100 grams The cake, 0.3 Emulgen 930, and 0.2 g thickener were ground with a sand mill to obtain a coating.

[0039] Among them, the components of the acrylic resin solutio...

Embodiment 2

[0044] A polyester-modified acrylate resin water-based paint, its formula is composed of 90 grams of acrylate resin solution, 8.5 grams of silica, 0.5 grams of Madaaflow leveling agent, 0.5 grams of xylene, and 0.3 grams of non-silicone dispersant , Thickener 0.2 grams.

[0045] The preparation method of the polyester-modified acrylate resin water-based paint is to take 50 grams of acrylate resin solution, 8.5 grams of silica, 0.5 grams of Madaaflow, and 0.5 grams of xylene, mix them evenly and grind them with a ball mill to make the particle size ≤10um; Take 40 grams of acrylate resin solution and add it to the ground mixture, and disperse it in 2000 grams of water at 18°C. After filtering and washing with water, a filter cake with 50% solid content and an average particle size of 100um is obtained; 100 grams of filter cake, 0.3 grams of non-silicone dispersant, and 0.2 grams of thickener were ground with a sand mill to prepare paint.

[0046] Among them, the components of the ac...

Embodiment 3

[0051] A polyester-modified acrylate resin water-based paint, and its formula is composed of 95 grams of acrylate resin solution and 5 grams of titanium dioxide.

[0052] The preparation method of the polyester-modified acrylate resin water-based paint is to take 50 grams of acrylate resin solution and 5 grams of titanium dioxide, mix them evenly and grind them with a ball mill to make the particle size ≤ 8um; take 45 grams of acrylate resin solution and add to the ground The latter mixture was dispersed in 2000 grams of water at 12°C, filtered and washed with water to obtain a filter cake with a solid content of 50%, with an average particle size of 95um; 100 grams of filter cake was ground with a sand mill to obtain coating.

[0053] Among them, the components of the acrylic resin solution are: 10 grams of methyl methacrylate, 10 grams of ethyl methacrylate, 5 grams of propyl methacrylate, 5 grams of butyl methacrylate, and 5 grams of pentyl methacrylate. , 10 grams of styrene, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com