Method for preparing high-solid-content and low-viscosity core-shell structure styrene-acrylic emulsion

A technology with a core-shell structure and high solid content, applied in adhesive types, ester copolymer adhesives, coatings, etc., can solve problems such as instability in the preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

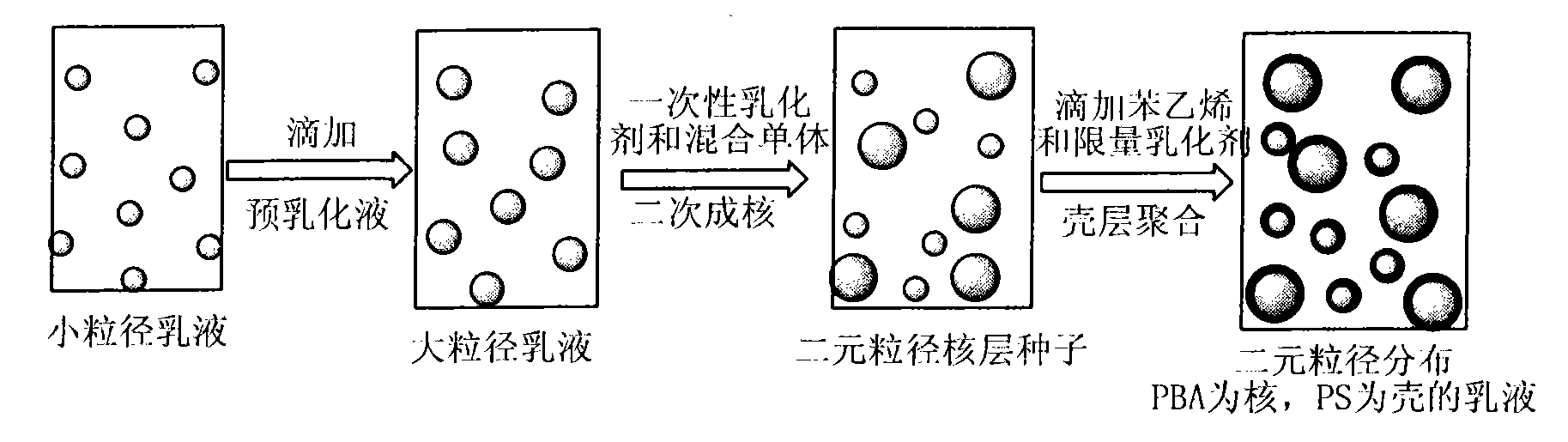

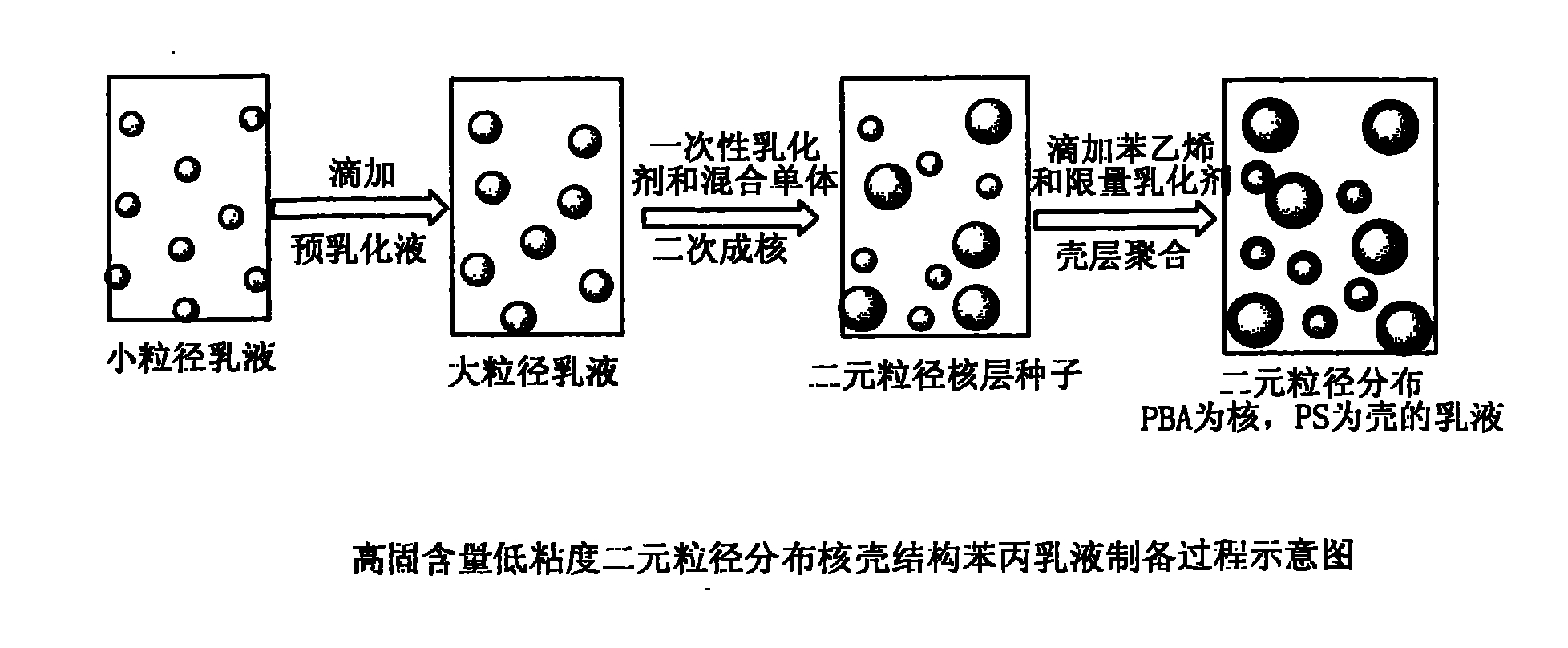

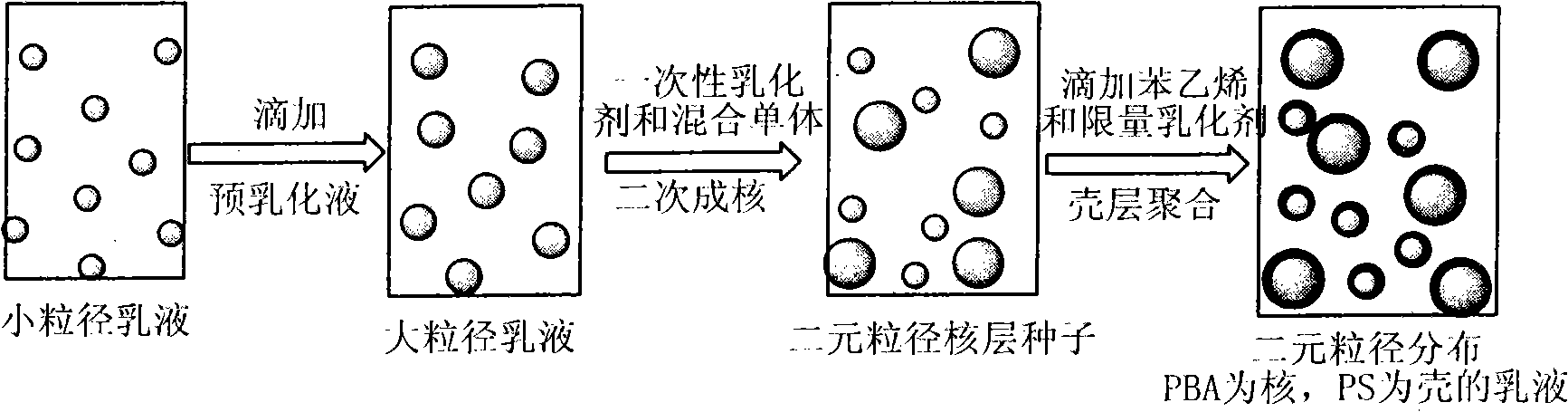

Image

Examples

Embodiment Construction

[0021] Formula 1: The latex prepared by this formula is suitable for use as a water-based adhesive. For example, it is used as sizing agent and glazing agent on the surface of paper, which has good bonding strength. Since the latex particle shell is styrene with a high glass transition temperature, it is not easy to stick to the roller when it is calendered after curing, and it is extruded. The surface gloss of the paper is high.

[0022] The emulsion obtained by the formula is a styrene-acrylic emulsion with a binary particle size distribution, the solid content is greater than 60%, and has the characteristics of good gloss, high solid content and low viscosity. Compared with traditional water-based emulsion adhesives, this product has the characteristics of fast drying, convenient sizing, uniform application and strong adhesion.

[0023]

[0024]

[0025] Formula 2: The latex in this formula is suitable for preparing monodisperse microspheres. The emulsion obtained f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com