Injectable water-absorbing and swelling bone cement and preparation method thereof

A water-absorbing swelling and bone cement technology, which is applied in medical science, surgery, surgical adhesives, etc., can solve the problems of joint wear, high strength, and high elastic modulus, and achieve the goals of reducing elastic modulus, improving strength, and improving bonding strength. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

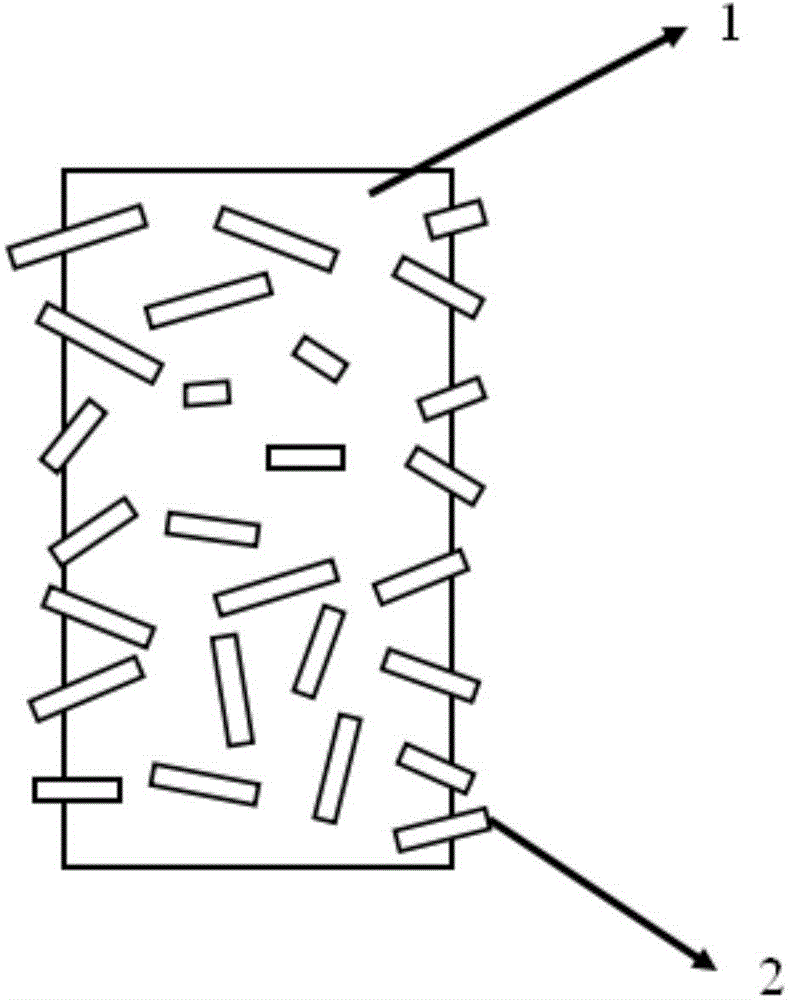

Image

Examples

preparation example Construction

[0037] The preparation of the water-absorbing resin can also adopt the reverse phase suspension polymerization method or the reverse phase emulsion polymerization method.

[0038] According to requirements, the water-absorbent resin fiber can be cut to an aspect ratio of 0.5-3:1.

[0039] Step 2, preparation of injectable bone cement precursor:

[0040] Prepare methyl methacrylate-styrene copolymer by suspension polymerization method, specifically: measure methyl methacrylate and styrene at a volume ratio of 7:2-4, and use the mass-volume ratio of dispersant to methyl methacrylate Weigh the dispersant at 0.012g / 7ml, weigh the initiator according to the mass volume ratio of the initiator and methyl methacrylate to be 0.25g / 7ml, add the dispersant and initiator to the mixed solution of methyl methacrylate and styrene in sequence , react at 80°C for 2h, and dry at 80°C to obtain methyl methacrylate-styrene copolymer, wherein the dispersant is composed of polyvinyl alcohol, sodiu...

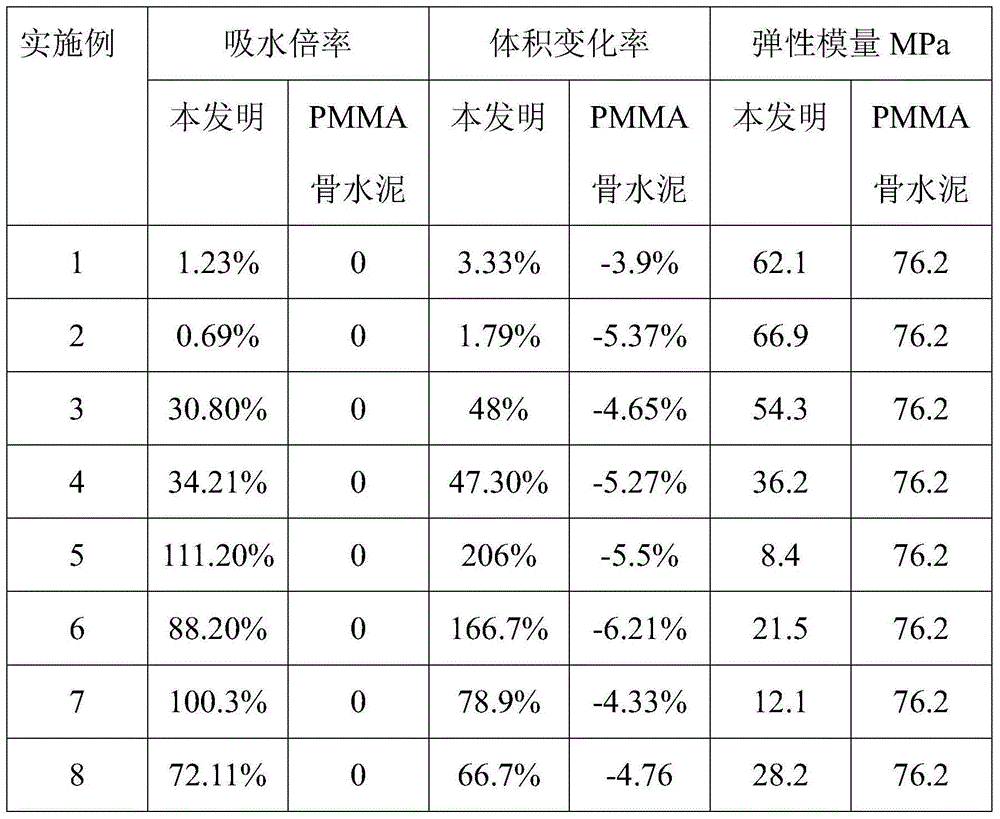

Embodiment 1

[0047] Step 1, preparing water-absorbent resin fibers:

[0048] Weigh 5.75g of sodium hydroxide, dissolve it in 25ml of distilled water, stir evenly, add 10ml of acrylic acid dropwise, react for 10min, add 0.9g of N-N methylenebisacrylamide, and wait until the N-N methylenebisacrylamide is completely dissolved , the solution was lowered to room temperature, and then 0.1 g of potassium persulfate was added, and after stirring for 3 minutes, the mixed solution was injected into a mold with a cylindrical cavity and an inner diameter of 1.0 mm with a syringe. Put it in a water bath, and after 30 minutes, when the temperature reaches 72°C, a gel-like water-absorbing resin is obtained. Dry in an oven at 70°C for 5 hours, cut the water-absorbent resin fibers into short fibers with a length of 2.0 mm, and obtain water-absorbent resin fibers with an inner diameter of 1.0 mm and an aspect ratio of 2:1.

[0049] Step 2, preparation of injectable bone cement precursor:

[0050] Measure ...

Embodiment 2

[0055] Step 1, preparing water-absorbent resin fibers:

[0056] Weigh 5.75g of sodium hydroxide, dissolve it in 20ml of distilled water, stir evenly, add 10ml of acrylic acid dropwise, react for 10min, add 0.9g of N-N methylenebisacrylamide, and wait until the N-N methylenebisacrylamide is completely dissolved , the solution was lowered to room temperature, and then 0.1 g of potassium persulfate was added, and after stirring for 3 minutes, the mixed solution was injected into a mold with a cylindrical cavity and an inner diameter of 0.5 mm with a syringe. Put it in a water bath, and after 40 minutes, when the temperature reaches 65°C, a gel-like water-absorbing resin is obtained. Dry in an oven at 65°C for 5.5 hours, cut the water-absorbent resin fibers into short fibers with a length of 0.5 mm, and obtain water-absorbent resin fibers with an inner diameter of 0.5 mm and an aspect ratio of 1:1.

[0057] Step 2, preparation of injectable bone cement precursor:

[0058] Measur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com