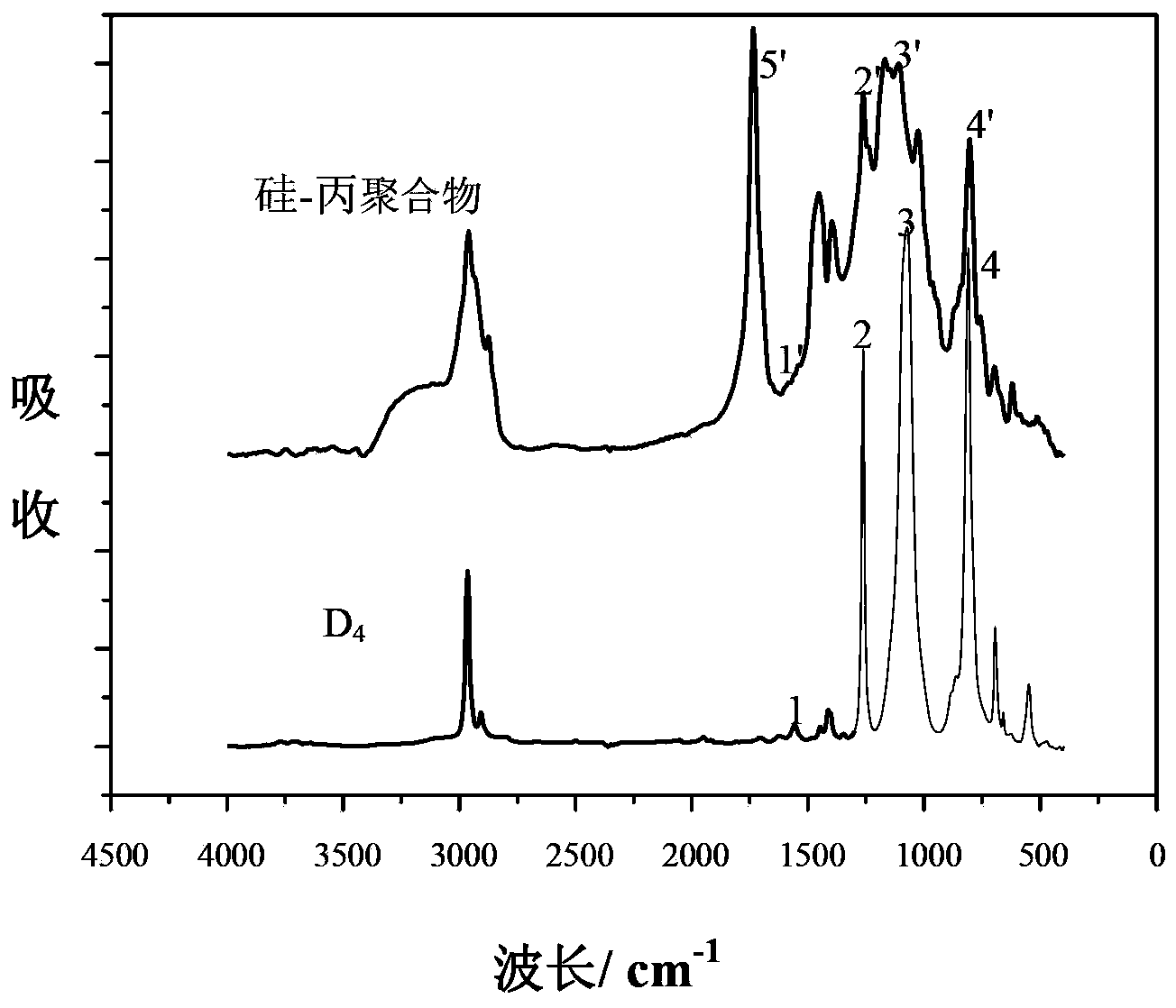

Silicone-acrylate emulsion with high organosilicon content and preparation method thereof

A silicon content, high organic technology, applied in the field of emulsion polymerization, can solve the problems of poor compatibility, low effective binding amount, easy phase separation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

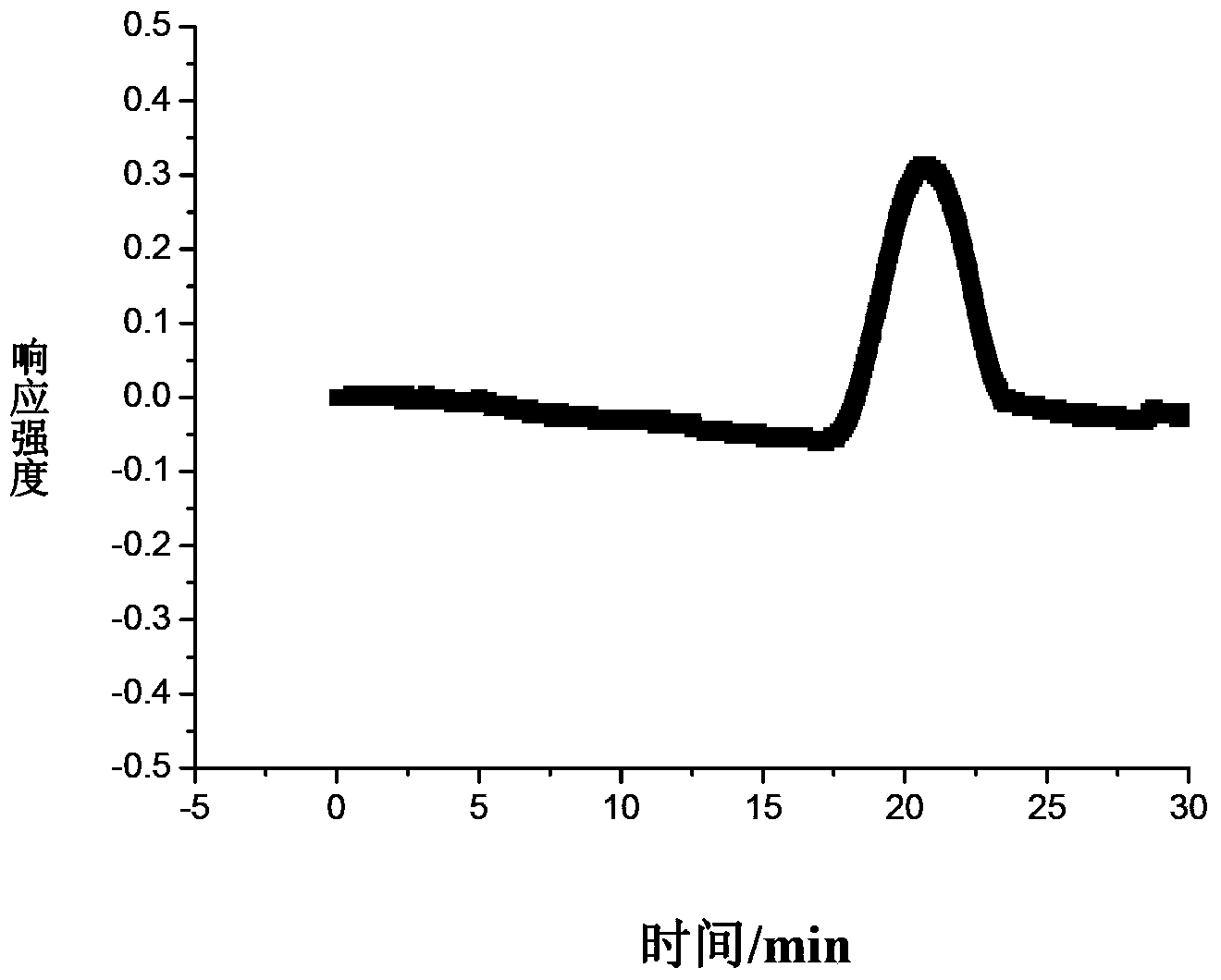

[0015] (1) Dissolve 1.20g of DBSA, 2.01g of 30wt% SE-10N and 0.20g of PE6100 in 130g of deionized water as the composite emulsifier, then transfer it to the reactor, and raise the temperature to 80°C under continuous stirring; add 4.03g of γ -Methacryloxypropylmethyldimethylsilane ZH-571 with 40.00g octamethylcyclotetrasiloxane D 4 The mixed solution was subjected to ring-opening reaction for 12 hours, cooled to 30° C., and the pH value of the system was adjusted to 7 with ammonia water.

[0016] (2) The temperature of the emulsion prepared in the above (1) step was raised to 80°C, and a mixture of 29.41g of methyl methacrylate, 29.40g of butyl acrylate and 1.20g of α-methacrylic acid and 0.3035g of supernatant was added dropwise within 1.5h. The initiator aqueous solution of ammonium sulfate (APS) and 20.00 g deionized water was kept for 4.5 hours, cooled to room temperature and adjusted to pH 7 with ammonia water, filtered, and discharged to obtain a silicon-acrylic emulsion...

example 2

[0024] In this embodiment, 0.81 g of emulsifier DBSA dodecylbenzenesulfonic acid is added dropwise during the preparation of the silicon-acrylic emulsion, and the others are the same as in Example 1.

example 3

[0026] In this embodiment, 1.60 g of emulsifier DBSA dodecylbenzenesulfonic acid is added dropwise during the preparation of the silicon-acrylic emulsion, and the others are the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com