Preparation method of polyaniline/stretchable fabric electrode material, obtained material and application of obtained material

A technology of fabric electrodes and polyaniline, which is used in the manufacture of conductive/semiconductive layer equipment, hybrid/electric double layer capacitor manufacturing, cable/conductor manufacturing, etc., can solve problems such as complex processes and achieve good hydrophilicity , good application value, good flexible effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

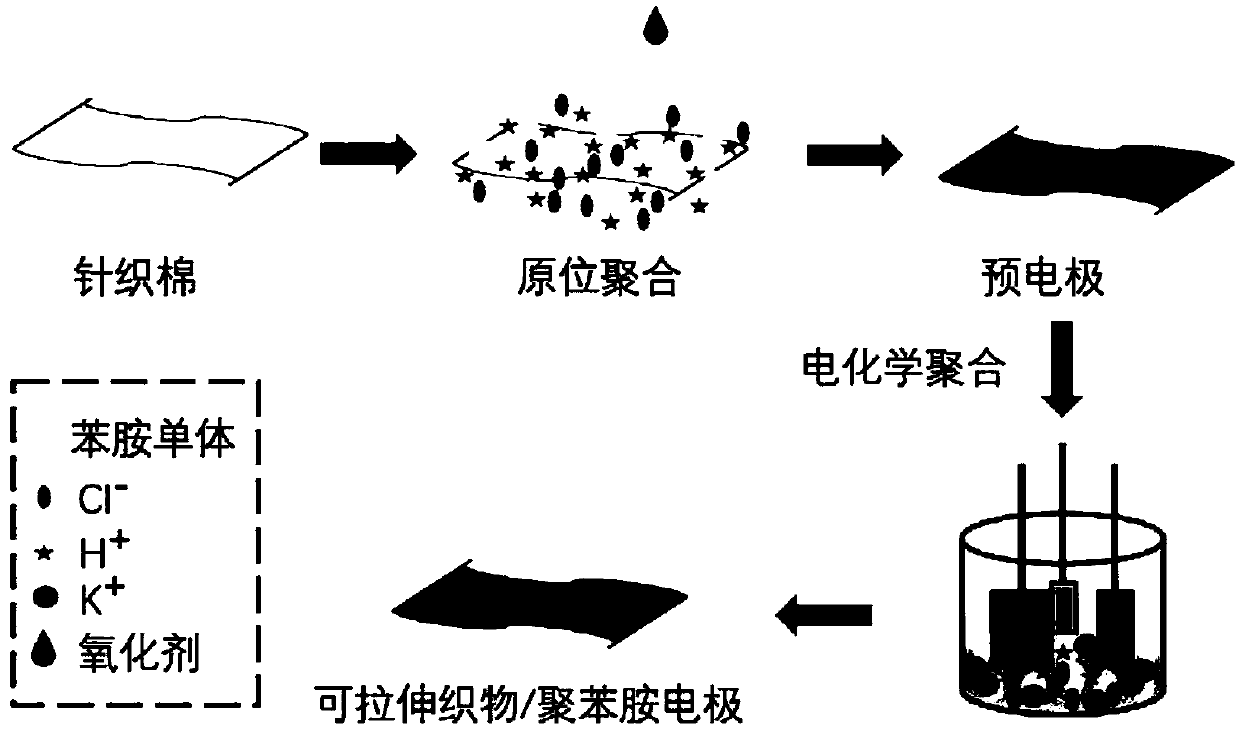

[0027] 1) Take a piece of 5cm×5cm knitted cotton fabric and soak it in aqueous hydrochloric acid solution containing 0.3mol / L aniline monomer for 5min, the concentration of HCl is 0.6mol / L;

[0028] 2) Add an aqueous solution of the oxidant ammonium persulfate dropwise to the above mixing system at 0°C and a stirring rate of 100r / min for in-situ chemical oxidation polymerization, wherein the molar ratio of the oxidant to the aniline monomer is 1.5:1, and the obtained The product was cleaned with deionized water and ethanol, and obtained the pre-electrode material after natural drying;

[0029] 3) The pre-electrode material obtained above is placed in a three-electrode system device containing an aniline monomer with a concentration of 0.05mol / L as a working electrode for electrochemical polymerization. The main components of the electrolyte in the system are KCl and HCl. 0.1mol / L, the counter electrode is a platinum electrode, the reference electrode is a calomel electrode of ...

Embodiment 2

[0032] 1) Take a 5cm×5cm piece of knitted polyester fabric and soak it in aqueous hydrochloric acid solution containing 0.5mol / L aniline monomer for 20min, the concentration of HCl is 0.5mol / L;

[0033] 2) Under the conditions of 25°C and a stirring rate of 300r / min, the aqueous solution of the oxidant ferric chloride hexahydrate was added dropwise to the above mixing system to carry out in-situ chemical oxidation polymerization, wherein the molar ratio of the oxidant to the aniline monomer was 1.5:1 , cleaning the obtained product with deionized water and ethanol, and obtaining a pre-electrode material after natural drying;

[0034] 3) The pre-electrode material obtained above is placed in a three-electrode system device containing a concentration of 0.2mol / L aniline monomer as a working electrode for electrochemical polymerization. The main components of the electrolyte in the system are KCl and HCl. The counter electrode is a platinum electrode, the reference electrode is a...

Embodiment 3

[0037] 1) Take a piece of 5cm×5cm woven cotton fabric and soak it in aqueous hydrochloric acid solution containing 0.1mol / L aniline monomer for 30min, the concentration of HCl is 1.0mol / L;

[0038] 2) Add an aqueous solution of ferric chloride hexahydrate dropwise to the above mixing system at 15°C and a stirring rate of 200r / min for in-situ chemical oxidation polymerization, wherein the molar ratio of oxidant to aniline monomer is 1:1 , cleaning the obtained product with deionized water and ethanol, and obtaining a pre-electrode material after natural drying;

[0039] 3) The pre-electrode material obtained above is placed in a three-electrode system device with a concentration of 0.01mol / L aniline monomer as a working electrode for electrochemical polymerization. The main components of the electrolyte in the system are KCl and HCl. The counter electrode is a platinum electrode, the reference electrode is a calomel electrode of a saturated KCl solution, and the electrochemical...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical conductivity | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com