Water-soluble cigarette packet laser transferring glue and preparation method thereof

A laser transfer, cigarette pack technology, applied in the direction of adhesive type, ester copolymer adhesive, etc., to achieve the effect of excellent bonding fastness, strong bonding force, and less residual monomers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0029] The preferred specific implementation of the water-based cigarette pack laser transfer adhesive of the present invention is:

[0030] Including a water-based acrylic emulsion polymer with a solid content of 45 to 55 wt%. The polymer is composed of any two or more of the following monomer mixtures in deionized water, emulsifiers, initiators, chain transfer agents, pH regulators, and water-based additives. Copolymerized under the action of agent:

[0031] Ethyl acrylate, propyl acrylate, butyl acrylate, isobutyl acrylate, methyl methacrylate, ethyl methacrylate, butyl methacrylate, isobutyl methacrylate.

[0032] The monomer mixture includes 25-60 parts by mass of C2-C4 alkyl acrylate monomer and 40-75 parts by mass of C1-C4 alkyl methacrylate monomer.

[0033] The emulsifier is an anionic emulsifier, including any one of alkylbenzene sulfonate, alkyl diphenyl ether disulfonate, succinic acid monoester sulfonate, polyoxyethylene alkyl ether sulfate or Two combinations, the amoun...

Embodiment 1

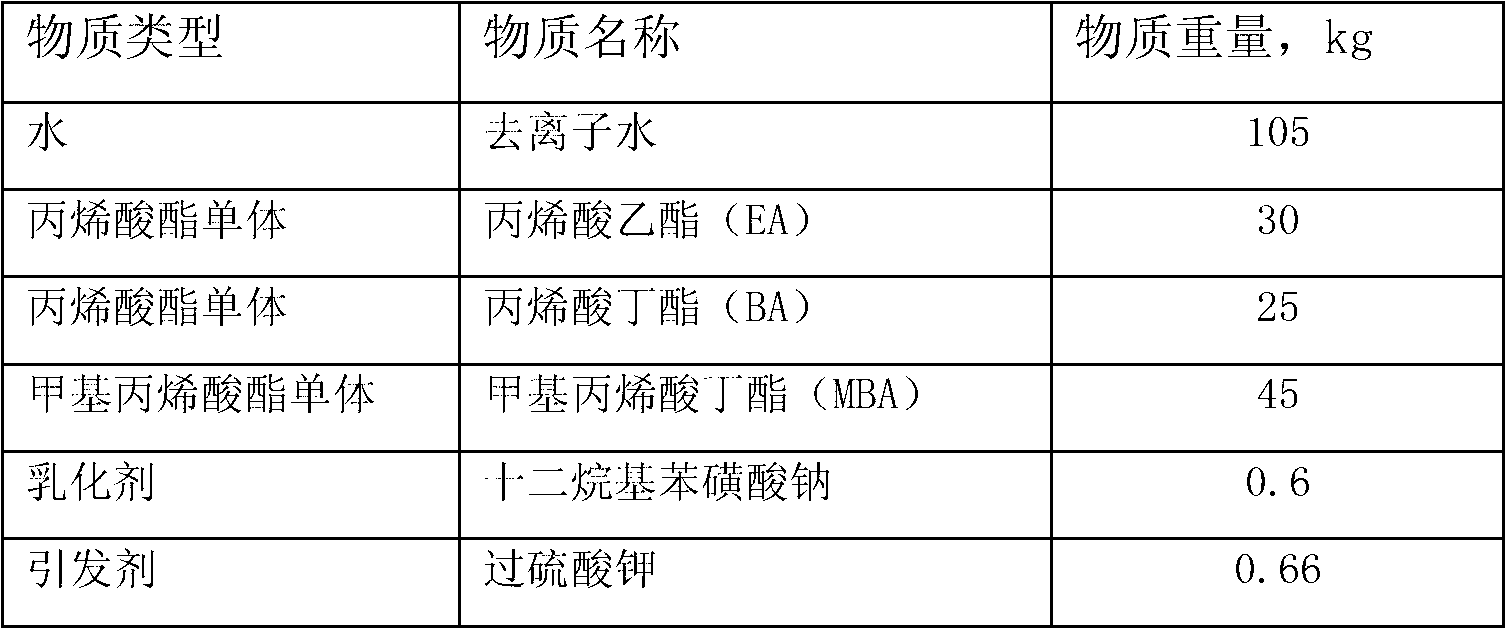

[0052] This embodiment provides a water-based cigarette packet laser transfer adhesive for preparing cigarette packet laser cardboard. The water-based cigarette packet laser transfer adhesive takes various raw materials according to the following formula, including:

[0053] Table 1 Ingredients formula

[0054]

[0055]

[0056] The preparation method includes the following steps:

[0057] Take each raw material according to the formula of the above-mentioned water-based cigarette pack laser transfer glue;

[0058] (a) Put deionized water, emulsifiers, monomers, and chain transfer agents that account for 50% of the total weight of deionized water into the emulsification kettle, start stirring and emulsify for not less than 30 minutes to obtain a pre-emulsion;

[0059] (b) Put 40% of the total weight of deionized water into the polymerization reactor, start stirring and increase the temperature, when the temperature reaches 75℃, put 5wt% of the pre-emulsion prepared in (a) above In the ...

Embodiment 2

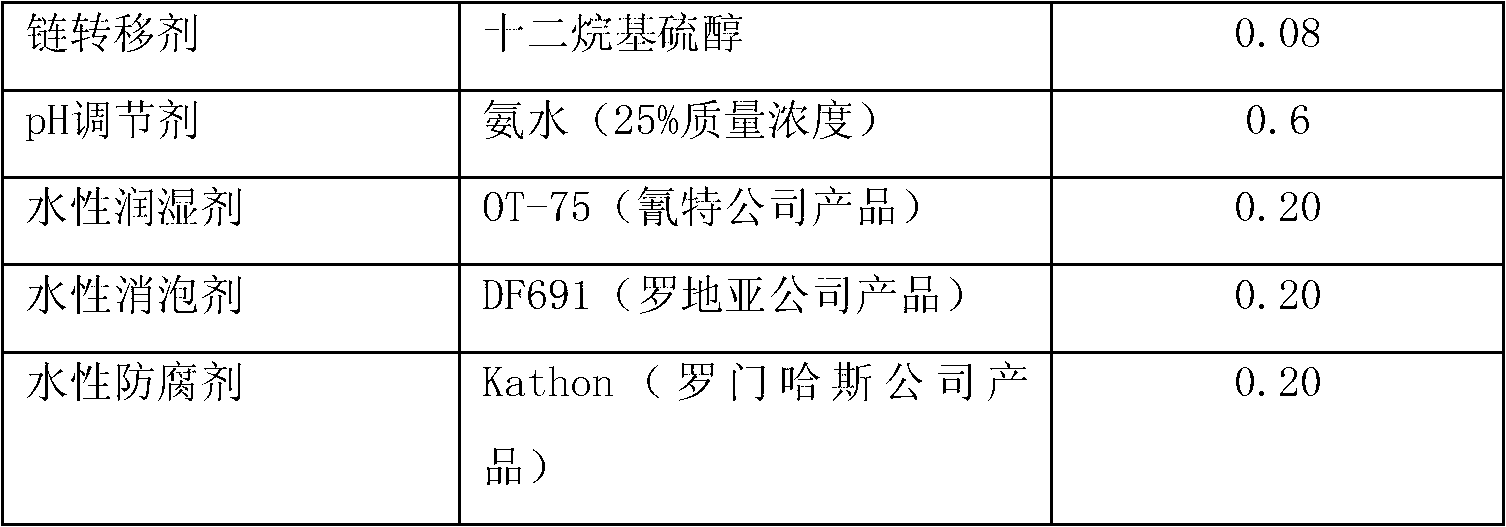

[0063] This embodiment provides a water-based cigarette packet laser transfer adhesive, which is used to prepare cigarette packet laser cardboard. The water-based cigarette packet laser transfer adhesive takes various raw materials according to the following formula, including:

[0064] Table 2 Ingredients formula

[0065] Substance type

Substance name

Material weight, kg

Water

Deionized water

115

Acrylate monomer

Ethyl Acrylate (EA)

10

Acrylate monomer

Butyl acrylate (BA)

30

Methacrylate monomer

Methyl methacrylate (MMA)

20

[0066] Methacrylate monomer

Ethyl methacrylate (MEA)

40

Emulsifier

Sodium Dialkyl Phenyl Ether Disulfonate

0.6

Emulsifier

Polyoxyethylene alkyl ether sodium sulfate

0.2

Initiator

0.66

Chain transfer agent

2-mercaptoethanol

0.06

pH regulator

Ammonia (25% mass concentration)

0.8

Water-based wetting agent

DO-75 (product of Tego)

0.20

Water-based defoamer

DF691 (Product of Rhod...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com