Amphiphilic temperature-sensitive block polymer base on phenylboronic acid and preparation method and application thereof

A temperature-sensitive block and amphiphilic technology, applied in the field of fractional purification of natural products, can solve the problems of time-consuming procedures, limited large-scale application, complex operation, etc., and achieve good compatibility and fast association/desorption kinetics Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0066] Example 1: Thermosensitive Polymer PEG 113 -b-PVBA 49 -b-PNIPAM 105 preparation of

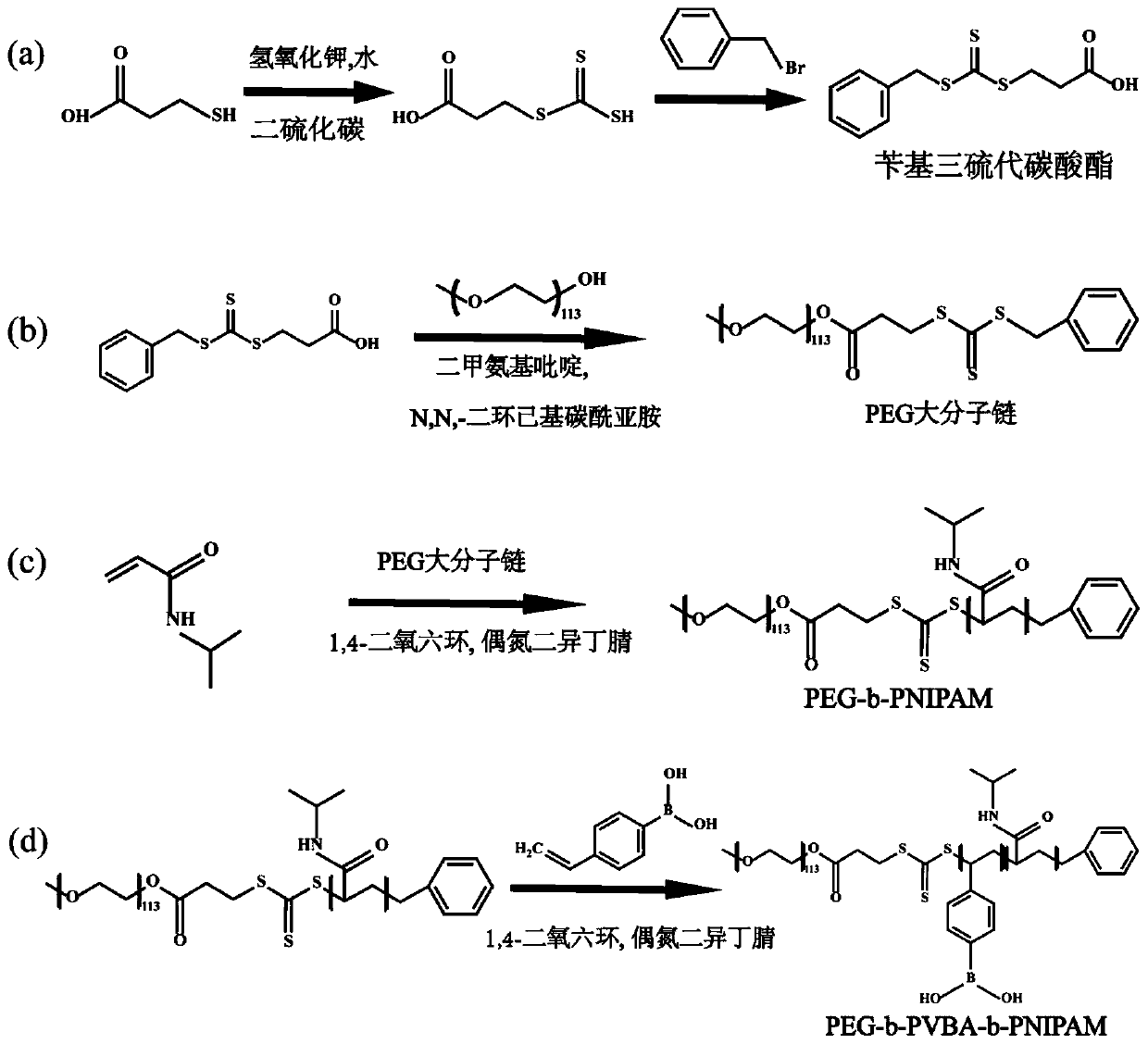

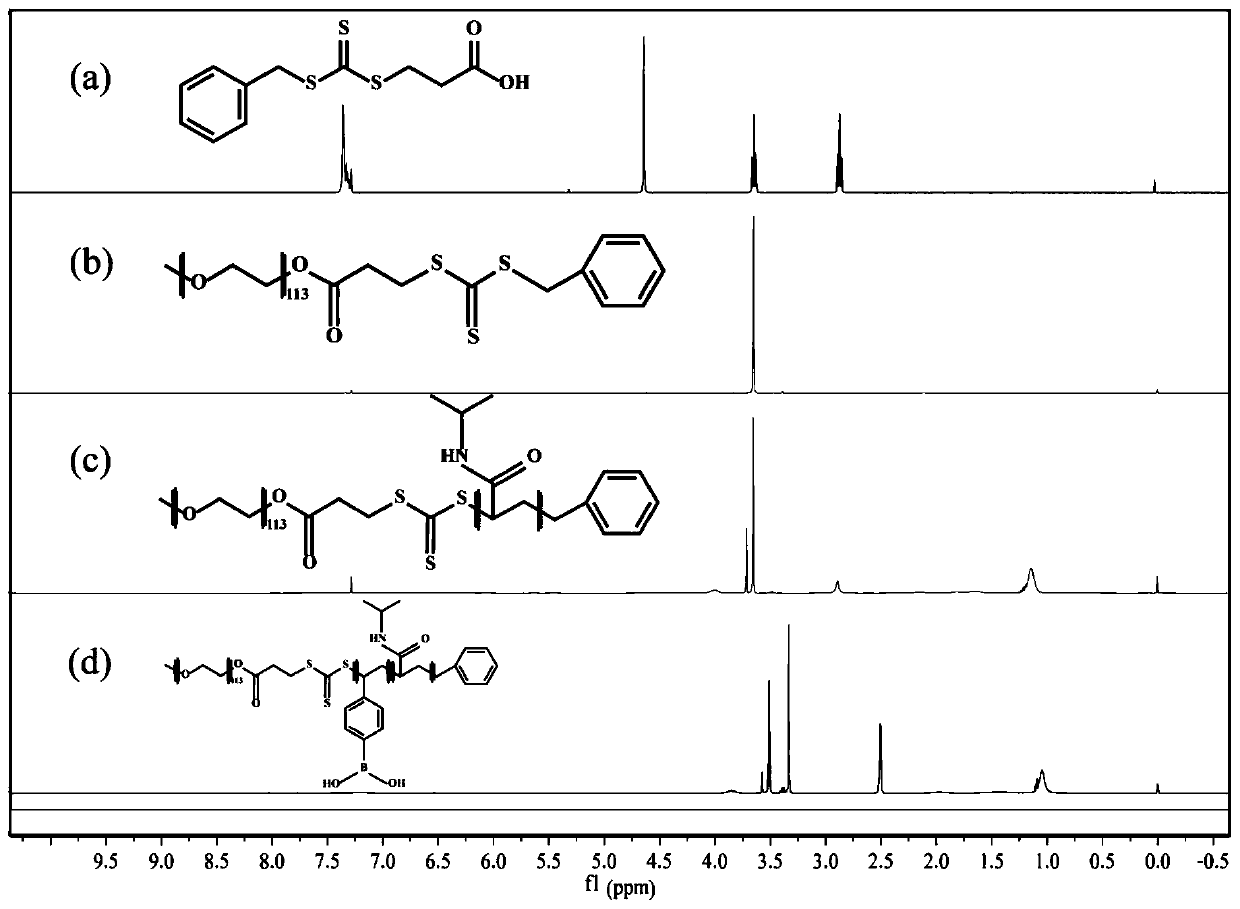

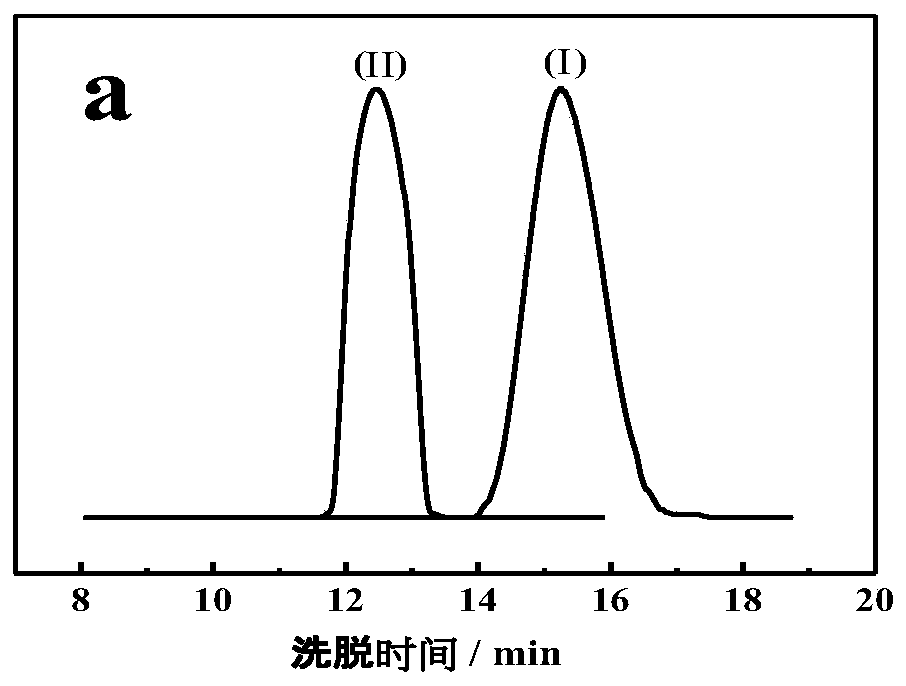

[0067] Synthesis of Triblock Copolymer PEG Using Reversible Addition-Fragmentation Chain Transfer Polymerization Mechanism 113 -b-PVBA 49 -b-PNIPAM 105 . First synthesize the PEG macromolecular chain, and then add the PNIPAM block and the BA block to the polymer in sequence. The detailed synthesis flow chart is as follows: figure 1 , in the figure a is the synthesis process of BTPA, b is the synthesis process of PEG macromolecular chain, and c is the synthesis process of PEG 113 -b-PNIPAM 105 The preparation process, d is PEG 113 -b-PVBA 49 -b-PNIPAM 105 preparation process. Specific steps are as follows:

[0068] (1) Preparation of benzyl trithiocarbonate (BTPA):

[0069]

[0070] Add 5.00 mL of 3-mercaptopropionic acid (MPA, 28.65 mmol) into 65.00 mL of KOH (1.84 mol / L) aqueous solution, and then add 3.65 mL of CS 2Slowly drop into the above mixed solution; then react...

Embodiment 2

[0090] Example 2: Thermosensitive Polymer PEG 113 -b-PVBA 49 -b-PNIPAM 105 preparation of

[0091] The preparation steps of benzyl trithiocarbonate (BTPA) and PEG macromolecular chains are the same as step (1) and step (2) in Example 1. Then include the following steps:

[0092] PEG 113 -b-PNIPAM 105 Preparation: Synthesize amphiphilic block copolymers by modifying PEG macromolecular chain transfer agent, including:

[0093] Put N-isopropylacrylamide, PEG macromolecular chains, azobisisobutyronitrile and 1,4-dioxane into a reaction vessel equipped with magnetic stirring; remove the air in the reaction vessel, and the solution is Protected oil bath reaction; after the reaction is completed, the solution is frozen in the refrigerator, and excess ether is used to remove impurities to obtain light yellow powder, which is PEG 113 -b-PNIPAM 105 , where b represents the combination of PEG macromolecular chains and PNIPAM in the form of block polymerization.

[0094] Wherein,...

Embodiment 3

[0101] Example 3: Thermosensitive Polymer PEG 113 -b-PVBA 49 -b-PNIPAM 105 preparation of

[0102] The preparation steps of benzyl trithiocarbonate (BTPA) and PEG macromolecular chains are the same as step (1) and step (2) in Example 1. Then include the following steps:

[0103] PEG 113 -b-PNIPAM 105 Preparation of:

[0104] Synthesis of amphiphilic block copolymers by modifying PEG macromolecular chain transfer agents, including:

[0105] Put N-isopropylacrylamide, PEG macromolecular chains, azobisisobutyronitrile and 1,4-dioxane into a reaction vessel equipped with magnetic stirring; remove the air in the reaction vessel, and the solution is Protected oil bath reaction; after the reaction is completed, the solution is frozen in the refrigerator, and excess ether is used to remove impurities to obtain light yellow powder, which is PEG 113 -b-PNIPAM 105 , where b represents the combination of PEG macromolecular chains and PNIPAM in the form of block polymerization.

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| number average molecular weight | aaaaa | aaaaa |

| number average molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com