Method for preparing three-dimensional natural fiber oil-absorbing material

An oil-absorbing material and natural fiber technology, applied in textiles, papermaking, non-woven fabrics, etc., can solve the problems of easy oil leakage and difficult recycling of loose fibers, and solve the difficulty of recycling, realize large-scale industrial application, and be easy to scale. The effect of large-scale industrial application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

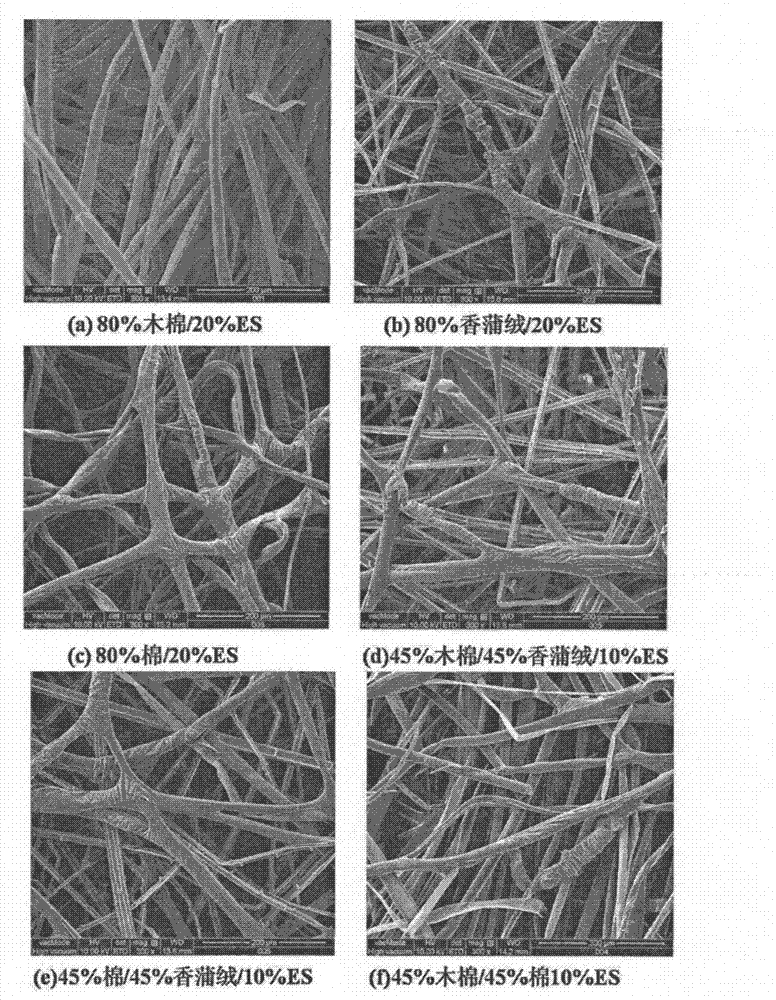

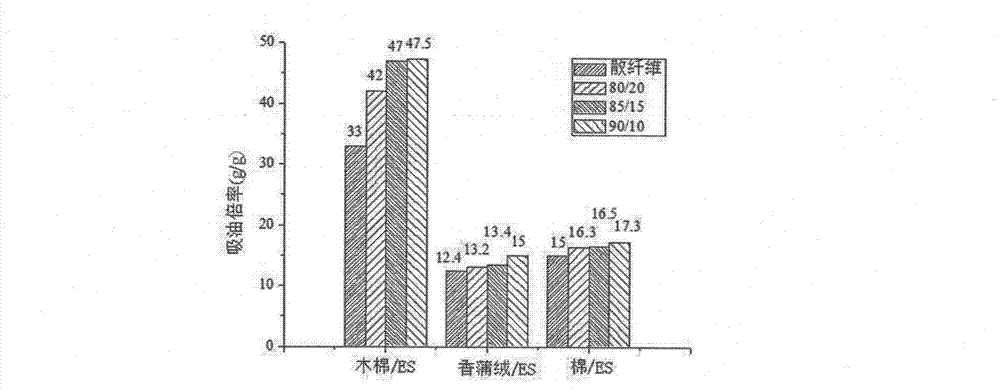

Embodiment 1

[0032] Open and mix kapok fiber and polypropylene / polyethylene sheath-core composite fiber (ES) according to the weight percentage ratio of 80:20, then process the fiber raw material after opening and mixing into fiber web through air-laid equipment, and cut Fiber web with a diameter of 8 cm. Place the fiber web inside a hot air oven at 140°C, and form a three-dimensional structure by heating and bonding under a pressure of 292Pa. The temperature of heating and bonding is 140°C, and the time is 30 minutes. Take it out and cool it to obtain kapok / ES oil-absorbing flakes.

Embodiment 2

[0034] Cattail velvet fiber and polypropylene / polyethylene sheath-core composite fiber (ES) are opened and mixed according to the weight percentage ratio of 80:20, and then the fiber raw material after opening and mixed is processed into a fiber web by air-laid equipment, and Fiber webs with a diameter of 8 cm were cut. Place the fiber web in a hot air oven at 140°C, and form a three-dimensional structure by heating and bonding under a pressure of 292Pa. The temperature of the heating and bonding is 140°C, and the time is 30 minutes. Take it out and cool it, and make cattail fleece / ES oil-absorbing flakes .

Embodiment 3

[0036] Opening and mixing ordinary cotton fibers and polypropylene / polyethylene sheath-core composite fibers (ES) according to a weight percentage ratio of 80:20, and then processing the opened and mixed fiber raw materials into fiber webs through air-laid equipment, and Fiber webs with a diameter of 8 cm were cut. Place the fiber web inside a hot air oven at 140°C, and form a three-dimensional structure by heating and bonding under a pressure of 292Pa. The temperature of heating and bonding is 140°C, and the time is 30 minutes. Take it out and cool it, and make ordinary cotton / ES oil-absorbing flakes .

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com