Patents

Literature

32results about How to "No new pollution" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Refining production method of glycerin

InactiveCN101759526ALess investmentSave energyIon-exchange column/bed processesHydroxy compound separation/purificationTrans esterificationBiodiesel

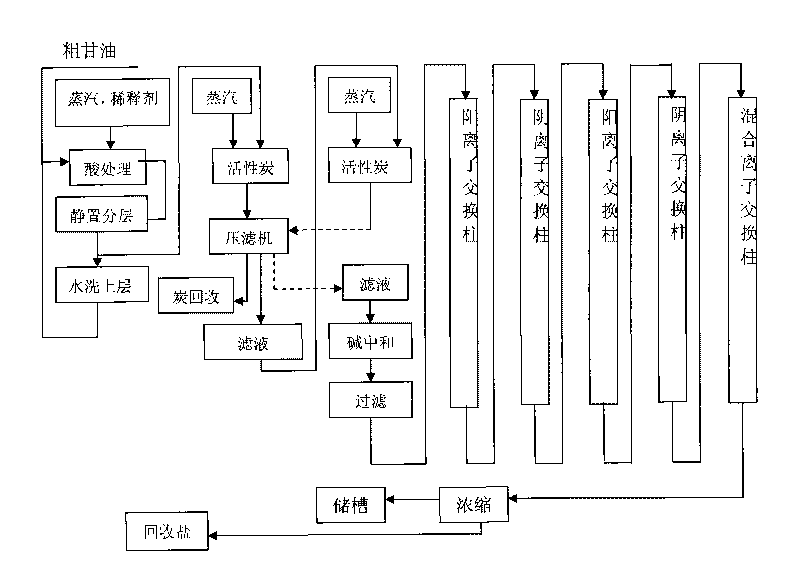

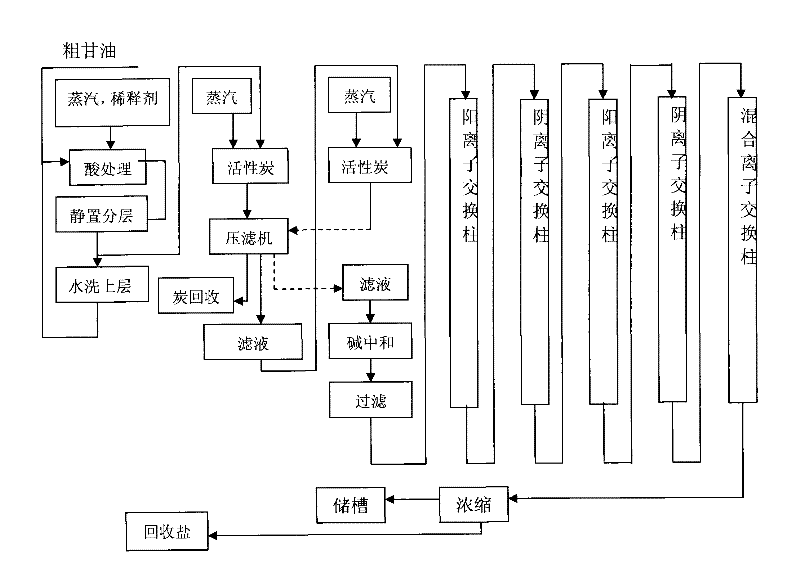

The invention provides a refining production method of crude glycerin. Byproducts of grease ester exchange or hydrolyzation are used as ingredients, and byproducts of biodiesel can also be used as ingredients. The method comprises the following steps: acidizing treatment, decolourization, alkali return for neutralization, concentration for salt removal, ion exchange and concentration treatment, wherein the ion exchange step comprises the substep of sequentially using cations, anions, cations, anions and zwitterions to exchange resin posts in a mixed way, the operation temperature of the resin posts is controlled between 40 and 60 DEG C, the flow rate is 15 mL / min, and finally, the pure glycerin solution is collected. The process of the invention has the advantages of simple operation condition, low temperature, little pollution and high yield, and can avoid the deterioration of the glycerin at the high temperature, the yield is higher than 97 percent, and the product purity is higher than 99.2 percent. The invention also provides a multiplex mixed type anion-cation exchange resin post combination device applicable to the method.

Owner:HUNAN ACAD OF FORESTRY

Waterproof glue for external wall ceramic tile

InactiveCN101735750AExcellent physical and chemical propertiesImprove the decorative effectAdhesivesEmulsionPreservative

The invention discloses a waterproof glue for external wall ceramic tile, which is formed by formulating acrylic emulsion, ethylene glycol, film forming auxiliary (dodecyl ester), alkali swelling thickener, antiseptic and defoaming agent, the waterproof glue has the advantages of being waterproof, joint-filling, transparent, rich in elasticity, environmentally-friendly, bright and clean, simple and convenient in applying, etc., and is free from toxicity, odor and new pollution even in case of the long-term use thereof and is also age resisting, therefore, the waterproof glue for external wall ceramic tile is an ideal product for environmental protection.

Owner:康信勇

Method for preparing three-dimensional natural fiber oil-absorbing material

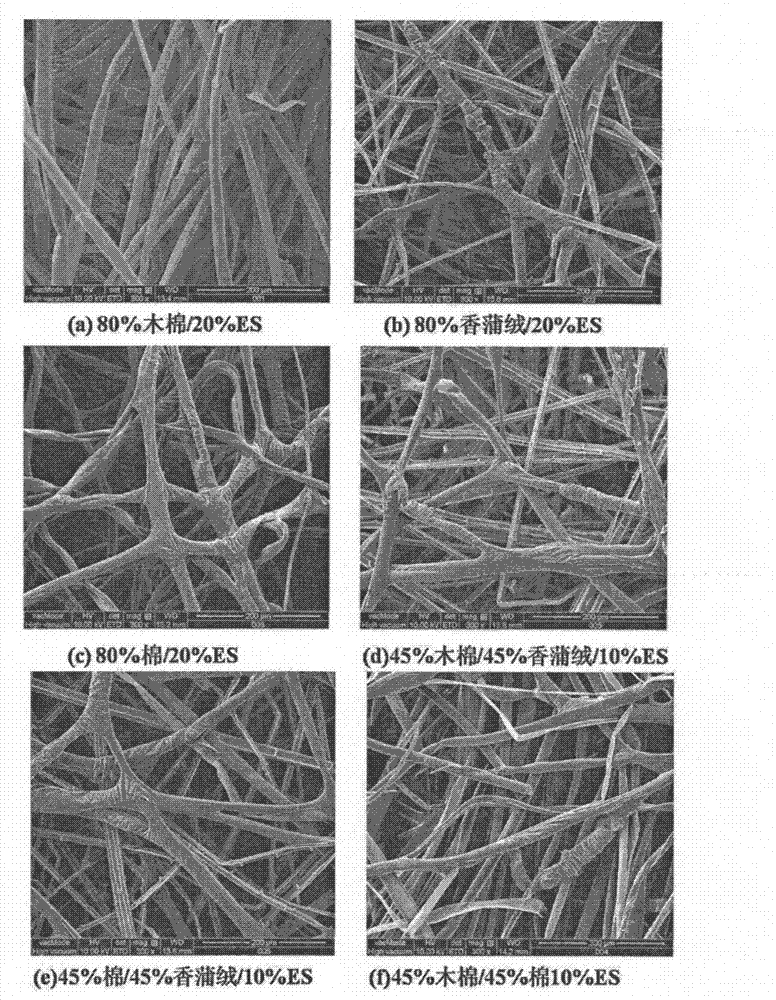

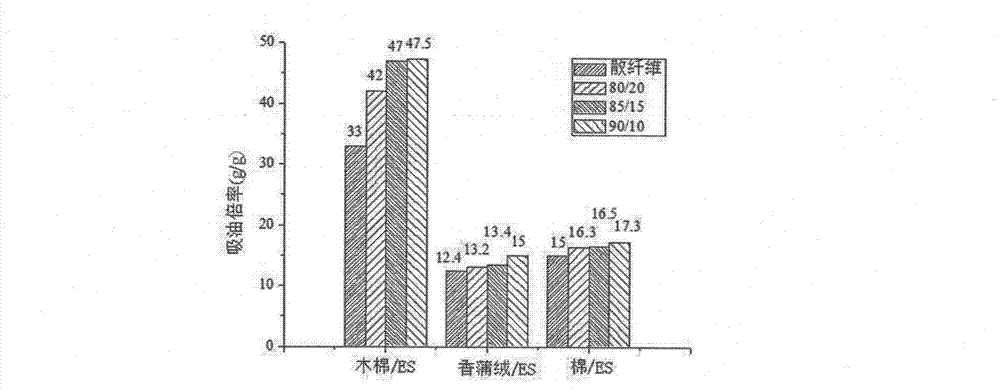

InactiveCN104328603AImprove oil absorption capacitySolve recycling difficultiesNon-woven fabricsBulrushCluster state

The invention provides a method for preparing a three-dimensional natural fiber oil-absorbing material. The method is characterized by comprising the following steps that 1, a cellulose fiber and a low-melting point fiber are loosened and blended, wherein the percentage by mass of the low-melting point fiber is 10 to 20 percent; 2, the loosened and blended fiber raw material is processed into a fiber net by airflow net-forming equipment; 3, the fiber net is heated and stuck into a three-dimensional structure, wherein the heating and sticking temperature is 130 to 160 DEG C, and the heating and sticking time is 20 to 100 minutes. According to the method for preparing the oil-absorbing material which takes a natural fiber, such as ceiba, bulrush floss, linter and bamboo pulp fiber as a raw material, a relatively ideal clustering state and a stable three-dimensional fiber clustering body structure of the natural fibers in a fiber clustering body are realized, the comprehensive oil-absorbing property of the fiber is improved, and the problems that scattered fibers are difficult in reclamation and oil leakage is caused again in the practical application of the fibers are well solved.

Owner:DONGHUA UNIV

Waste gum powder flexible acrylic acid water gap filling material and its preparation method

The present invention belongs to the field of building material technology, in the concrete, it relates to a waste rubber powder flexible acrylic acid water-base joint-filling material and its preparation method. It is made up by using rubber powder obtained by processing waste tyre as aggregate, and mixing it with the chemical raw materials of acrylic acid elastic emulsion, sodium hexametaphosphate, sodium benzoate, ethylene glycol, propylene glycol, polydimethylsiloxane, methyl cellulose, calcium carbonate and colouring agent according to a certain mixing ratio.

Owner:TONGJI UNIV

Flexible acrylic acid waste polyurethane water composite joint filling material and its preparation method

The present invention belongs to the field of building material technology, in the concrete, it relates to a flexible acrylic acid waste polyurethane water-base composite joint-filling material and its preparation method. It is made up by using powder obtained by processing waste polyurethane material as aggregate and mixing it with the chemical raw materials of acrylic acid elastic emulsion, sodium hexametaphosphate, sodium benzoate, ethylene glycol, propylene glycol, polydimethylsiloxane, methyl cellulose, calcium carbonate and colouring agent according to a certain mixing ratio.

Owner:TONGJI UNIV

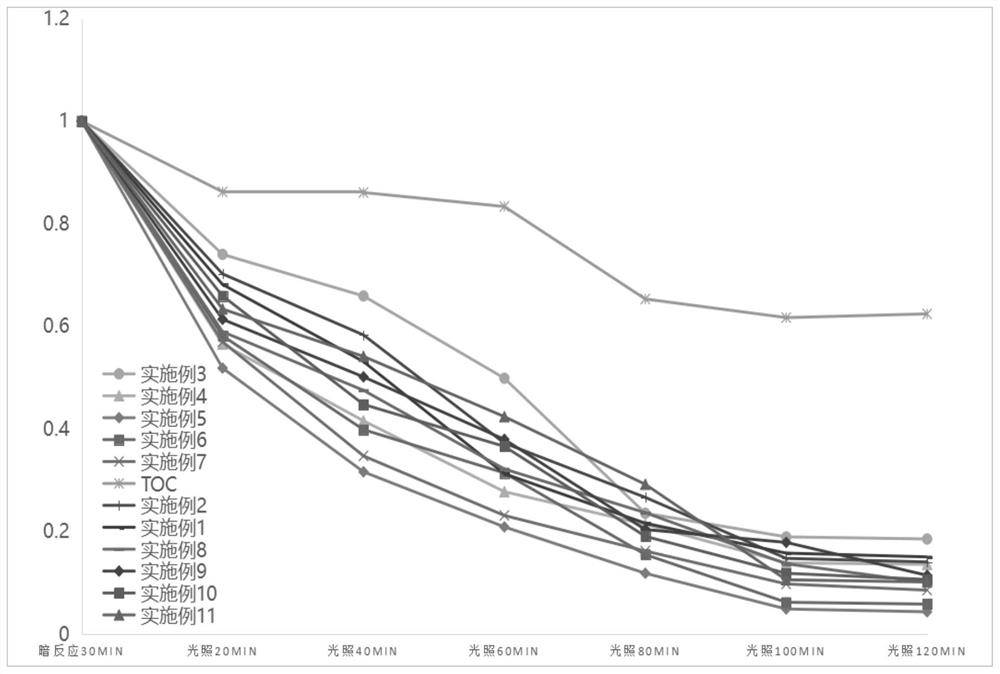

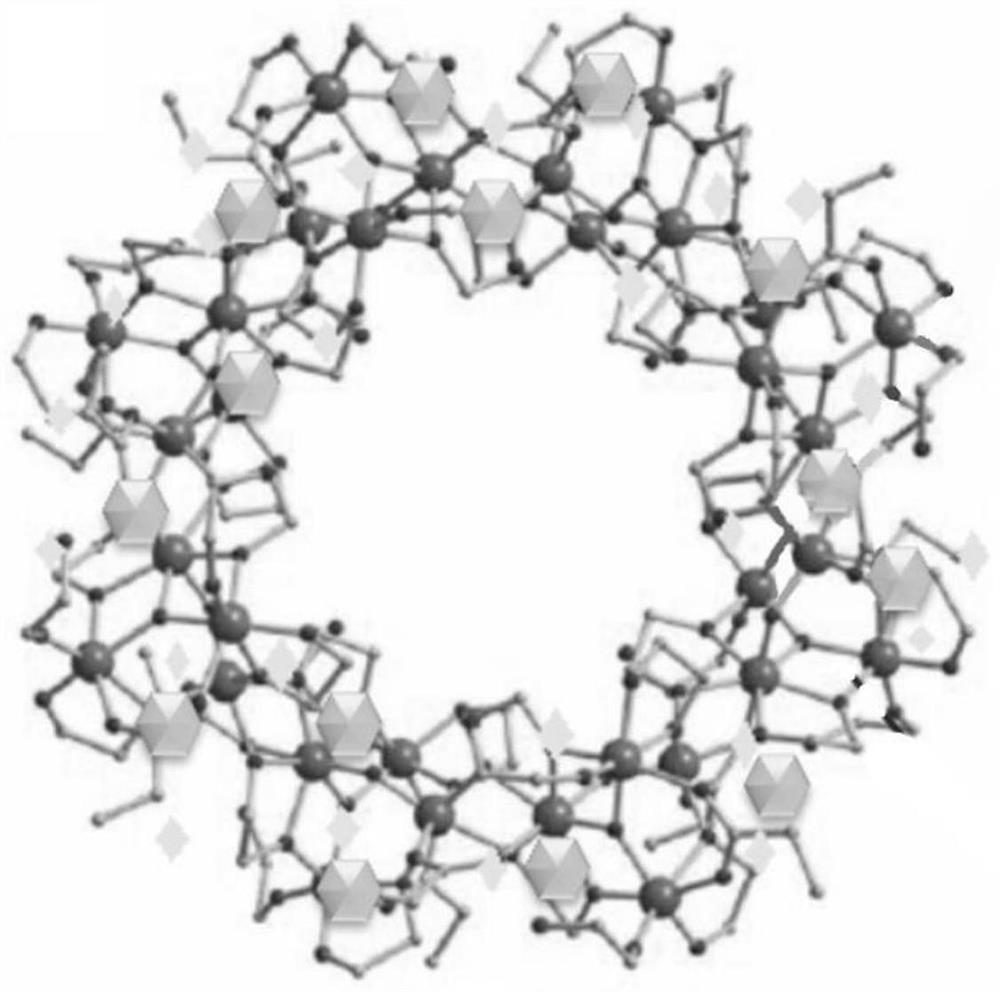

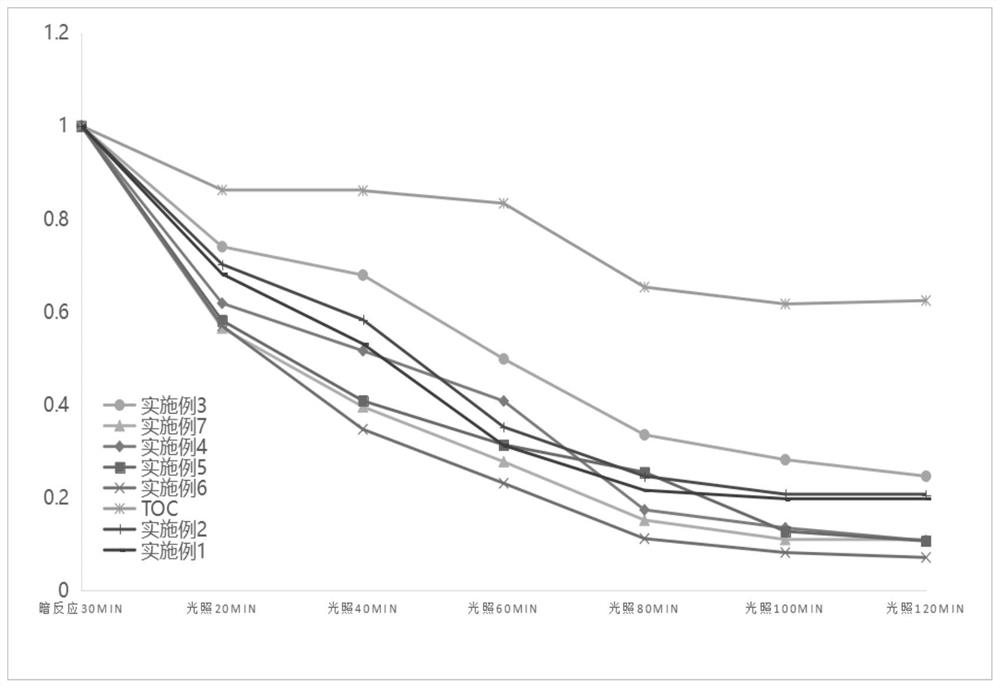

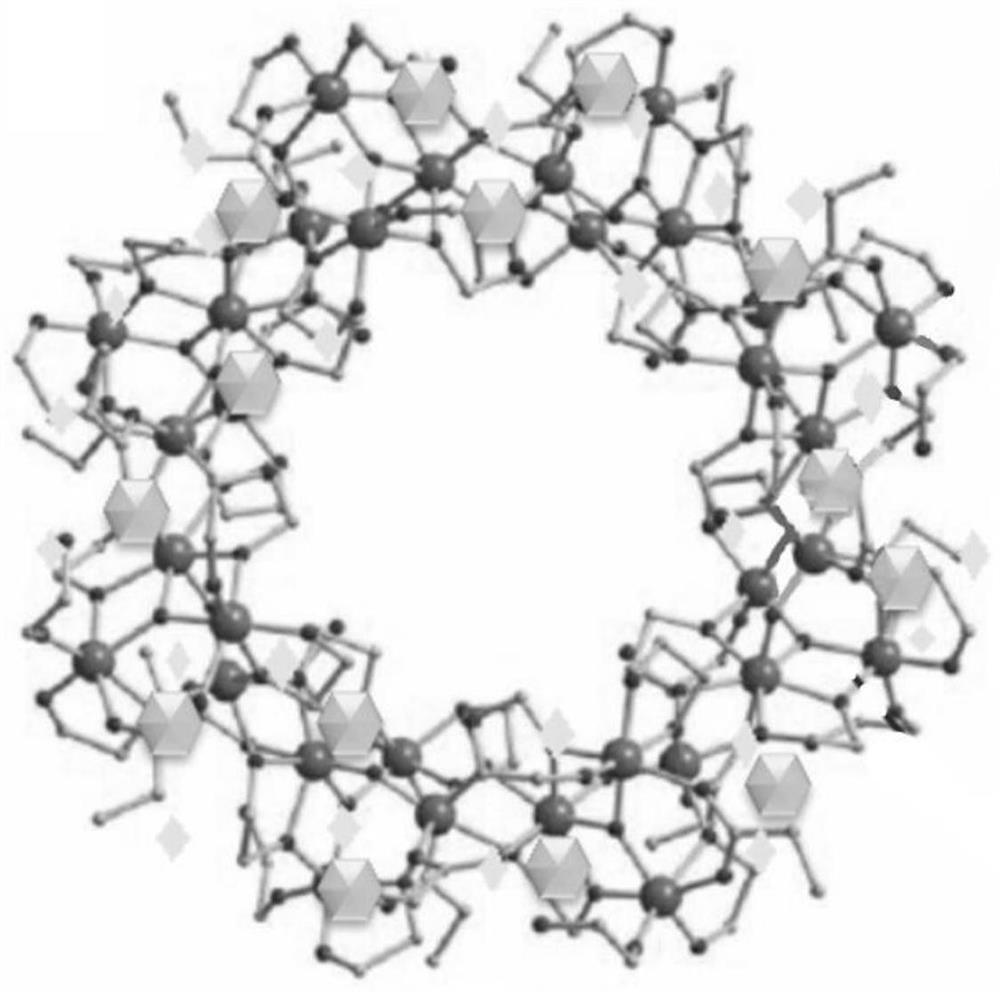

Pd/TOC photocatalyst, Pd/CdS/TOC photocatalyst, preparation method and application thereof

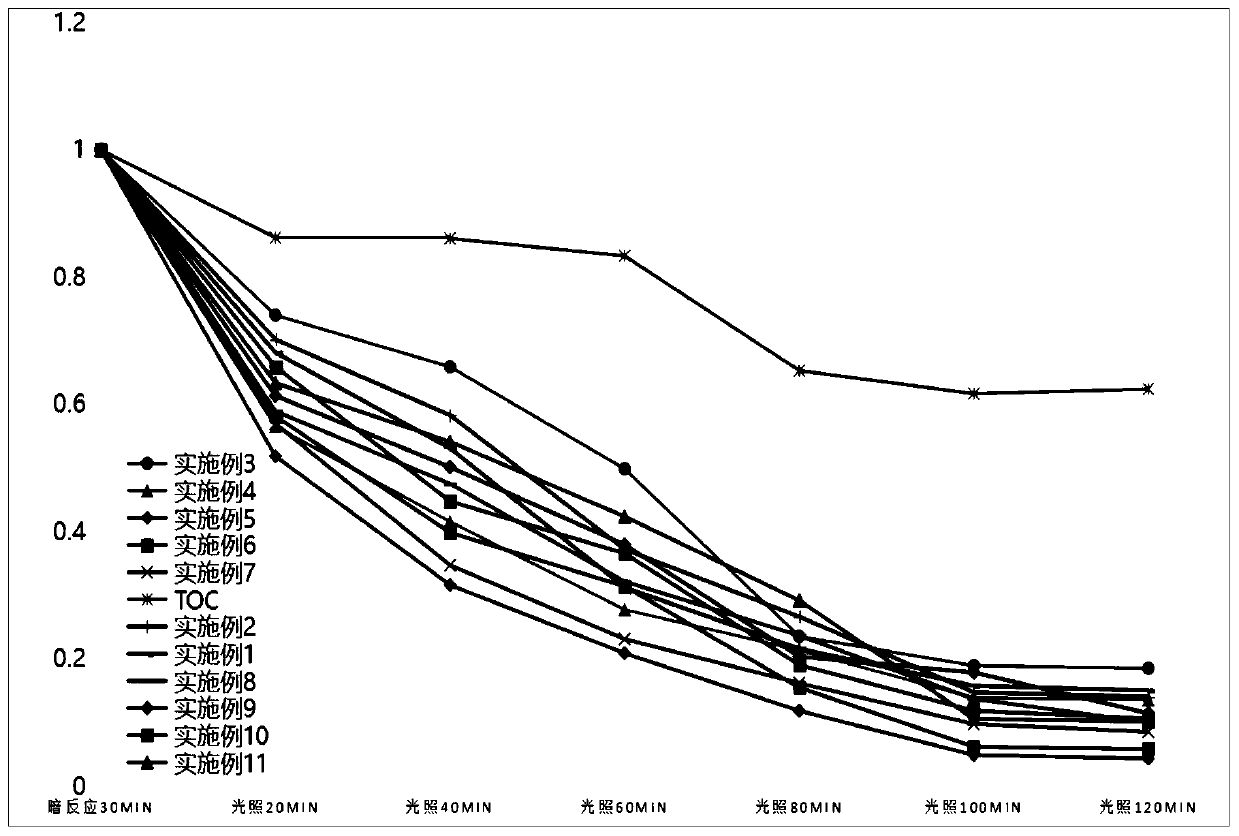

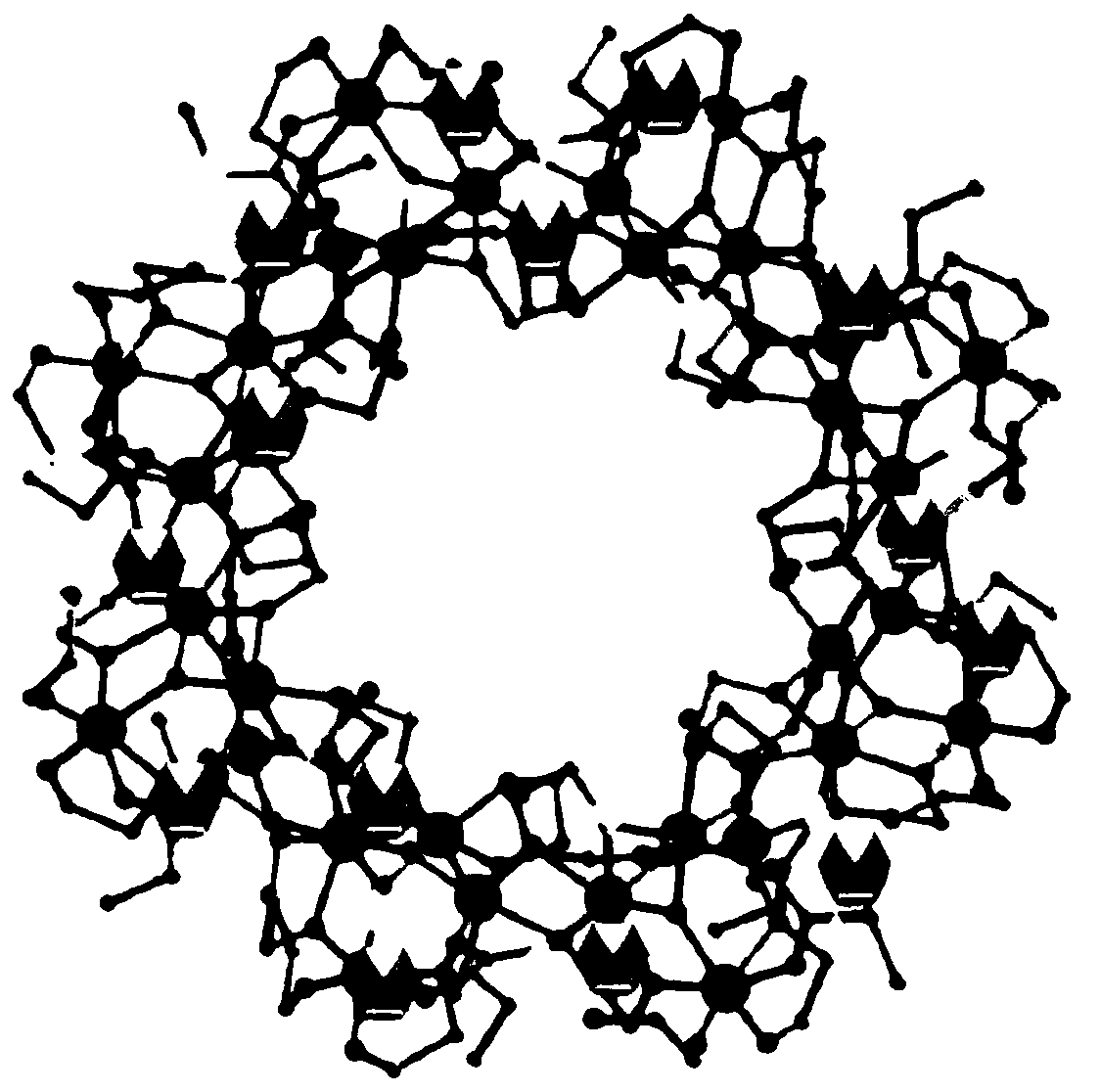

ActiveCN109876829AImprove thermal stabilityHigh hydrothermal stabilityPhysical/chemical process catalystsWater/sewage treatment by irradiationWastewaterDichlorophenol

The invention discloses a Pd / TOC photocatalyst, a Pd / CdS / TOC photocatalyst, a preparation method and an application thereof. The Pd / TOC photocatalyst is prepared by taking TOC as a load object and loading Pd on TOC. The Pd / CdS / TOC photocatalyst is prepared by further loading CdS on the basis of the Pd / TOC photocatalyst. Various photocatalysts prepared according to the invention are all green and environment-friendly materials; no new pollution is generated after degradation of the photocatalysts; degradation efficiency is high; applicable environment is extensive; the photocatalysts can be used for treating wastewater; the efficiency of degrading 2,4-dichlorophenol is high; the popularization and application of photocatalysts have huge advantages.

Owner:CHANGAN UNIV

Comprehensive utilization method for Bayer red mud

PendingCN111137907AHigh purityLow costProcess efficiency improvementAlkali metal sulfites/sulfatesSodium carbonateLeaching (metallurgy)

The invention provides a comprehensive utilization method for Bayer red mud, belonging to the technical field of metallurgy and chemical engineering. The method comprises the following steps: firstly,mixing the Bayer red mud with concentrated sulfuric acid, and conducting complete salinization under a low-temperature condition to obtain sulfated red mud; then, roasting the prepared sulfated red at a temperature of 600-900 DEG C, subjecting a roasted product to water leaching, and then conducting solid-liquid separation to obtain a sodium-rich low-iron leachate and high-iron red mud oxidized clinker; and finally, adding sodium carbonate into the leachate, carrying out solid-liquid separation, and carrying out evaporative crystallization on a filtrate to obtain sodium sulfate crystals. Thehigh-iron red mud oxidation clinker can be used for extracting aluminum. According to the method, high-purity sodium sulfate can be prepared, and aluminum can be extracted, so the waste is turned intowealth, and harm caused by direct accumulation of the red mud is eliminated.

Owner:UNIV OF SCI & TECH BEIJING

Method for recovering lithium and potassium from high-lithium-potassium anode carbon residues or high-lithium-potassium electrolytes

ActiveCN111321302AFull recoveryHigh recovery rateProcess efficiency improvementLithiumPhysical chemistry

The invention discloses a method for recovering lithium and potassium from high-lithium-potassium anode carbon residues or high-lithium-potassium electrolytes. The method comprises the following stepsthat (1) the high-lithium-potassium anode carbon residues or the high-lithium-potassium electrolytes are finely ground as raw materials, mixed with a concentrated sulfuric acid solution, and heated to 280-500 DEG C for reacting; (2) water is added into the reacted materials for leaching, and primary filtrate is filtered and separated out; (3) the pH value is adjusted to be equal to 6-8 when the temperature of the primary filtrate is less than or equal to 30 DEG C, and secondary filtrate is obtained through filtering and separating; (4) the secondary filtrate is cooled to minus 5 DEG C to-minus 10 DEG C, and Na2SO4 is separated out; third filtrate is filtered and separated out; (5) after the third filtrate is heated to 90-100 DEG C or boiled, Na2CO3 is added and Li2CO3 is precipitated andseparated out, and the Li2CO3 and fourth filtrate are filtered and separated out; and (6) the fourth filtrate is cooled to minus 5 DEG C to-minus 10 DEG C, and Na2SO4 is precipitated out, a K2SO4 solution is filtered to separated out, and a K2SO4.xH2O product or a K2SO4 product is obtained by concentrating or dehydrating. The method is low in process flow cost and convenient to operate, almost does not generate new pollution while the waste is fully recovered, and has a good popularization prospect.

Owner:SHENYANG BEIYE METALLURGIGAL TECH CO LTD

Soft pellet aquatic feed

PendingCN105029094AReduce production energy consumptionEasy to useFood preservationAnimal feeding stuffAnimal scienceArginine

The invention provides soft pellet aquatic feed which is convenient to use and can replace alive small trash fishes. The soft pellet aquatic feed is mainly prepared from fishmeal, seaweed meal, beer yeast powder, fermented soybean meal, poly-phycocolloid, lysine, methionine, arginine, monopotassium phosphate, choline chloride and the like; the moisture content is more than or equal to 20% and less than or equal to 40%. The soft pellet aquatic feed can be produced in a large scale in a factory-like manner; meanwhile, the soft pellet aquatic feed can be preserved at a room temperature for more than 30 days and does not go bad.

Owner:福建格林生物科技有限公司 +1

Clay acrylic surface decorating material and its preparing method

The invention is a kind of dual environmental protection building surface ornamenting material produced by using brick powders of grinded waste construction clay bricks as main materials and its producing method. The invention makes clay brick powders as main materials, and is compounded from such chemical industry materials as acrylic acid emulsion, sodium hexametaphosphate, sodium benzoate, glycol, trimethylene glycol, polydimethyl siloxanes, methylcellulose and titanium oxide powder as per certain proportion. The invention has simple technics, convenient and sanitary construction, and can be used both in upscale wall surface and surfaces of column, tablet and board. After ornamented, it has elegant and vivid brick wall style, especially suitably used for outer ornament and repair of building wall surfaces whose outer walls need brick wall structures.

Owner:TONGJI UNIV

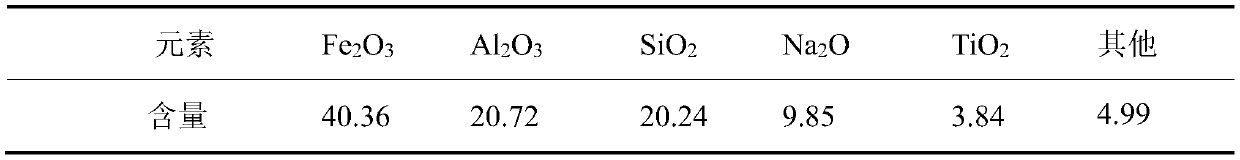

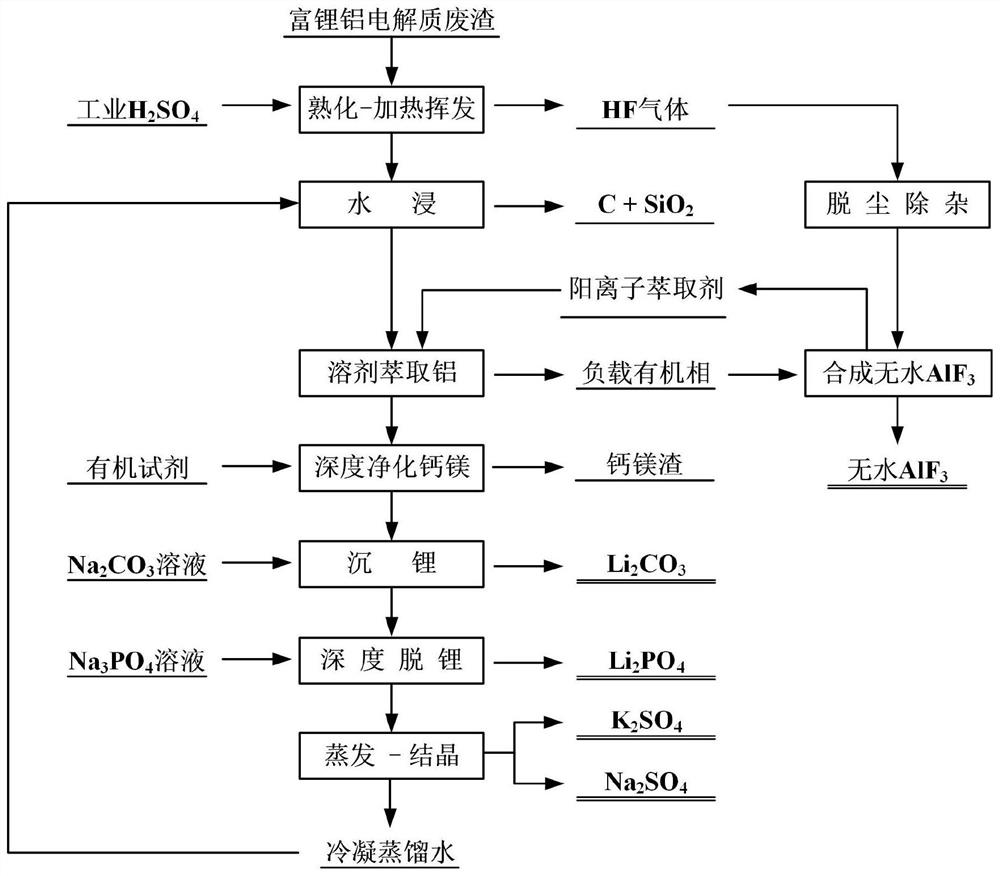

Method for efficiently extracting lithium from lithium-rich aluminum electrolyte waste residues and preparing anhydrous aluminum fluoride

ActiveCN113718107AAchieve recyclingThorough removalAluminium fluoridesProcess efficiency improvementAluminum fluorideLithium

The invention belongs to the technical field of nonferrous metal extraction. The invention provides a method for efficiently extracting lithium from lithium-rich aluminum electrolyte waste residues and preparing anhydrous aluminum fluoride. According to the method, HF gas generated by curing and volatilizing concentrated sulfuric acid is subjected to dust removal and impurity removal and then directly makes contact with an aluminum-loaded organic phase to prepare anhydrous AlF3, the purity of the synthesized anhydrous AlF3 is high, the prepared anhydrous AlF3 can be returned to the aluminum electrolysis process to serve as a cosolvent, and cyclic utilization of aluminum and fluorine is achieved. According to the method, the lithium resource in the lithium-rich aluminum electrolyte waste residues is recycled in the form of Li2CO3, the recycling rate is high, the product purity is high, and high economic benefits are achieved. According to the method, sodium dimethyl dithiocarbamate solution is used as a precipitator to deeply purify and remove calcium, magnesium and aluminum, the impurity element removal effect is thorough, and raw materials are prepared for the step of precipitating lithium in sodium carbonate. In the treatment process of the lithium-rich aluminum electrolyte waste residues, various components can be efficiently recycled, and new pollution is not generated while waste materials are fully recycled.

Owner:CENT SOUTH UNIV

Luminous insecticidal multifunction surface material and preparation method thereof

InactiveCN101235178AExcellent physical and chemical propertiesExcellent contact effectBiocideAnimal repellantsEmulsionPermethrin

The invention relates to a luminous disinsection multifunctional surface material and a corresponding preparation method, belonging to construction material technical field, which uses permethrin, SrAI2O4:Eu2+ as main materials and adds styrene-acrylic emulsion, sepiolite and other materials. The invention has simple process, easy operation, clearness and wide application in hospital, canteen, company and channel or the like. Via the luminous property, the invention can be used as indication and decorative material, particularly as aqueous environment-friendly material, without toxicity, smell and pollution in production, construction and application.

Owner:TONGJI UNIV

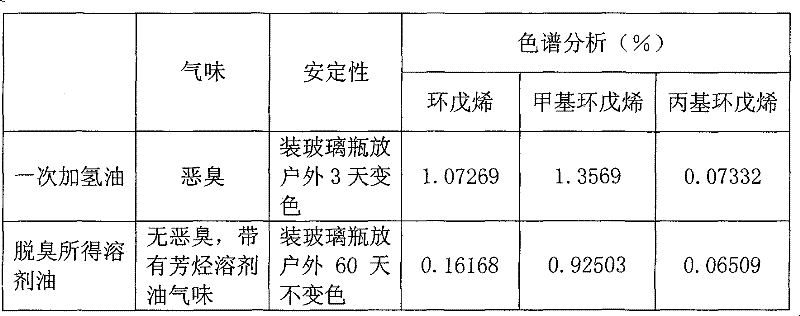

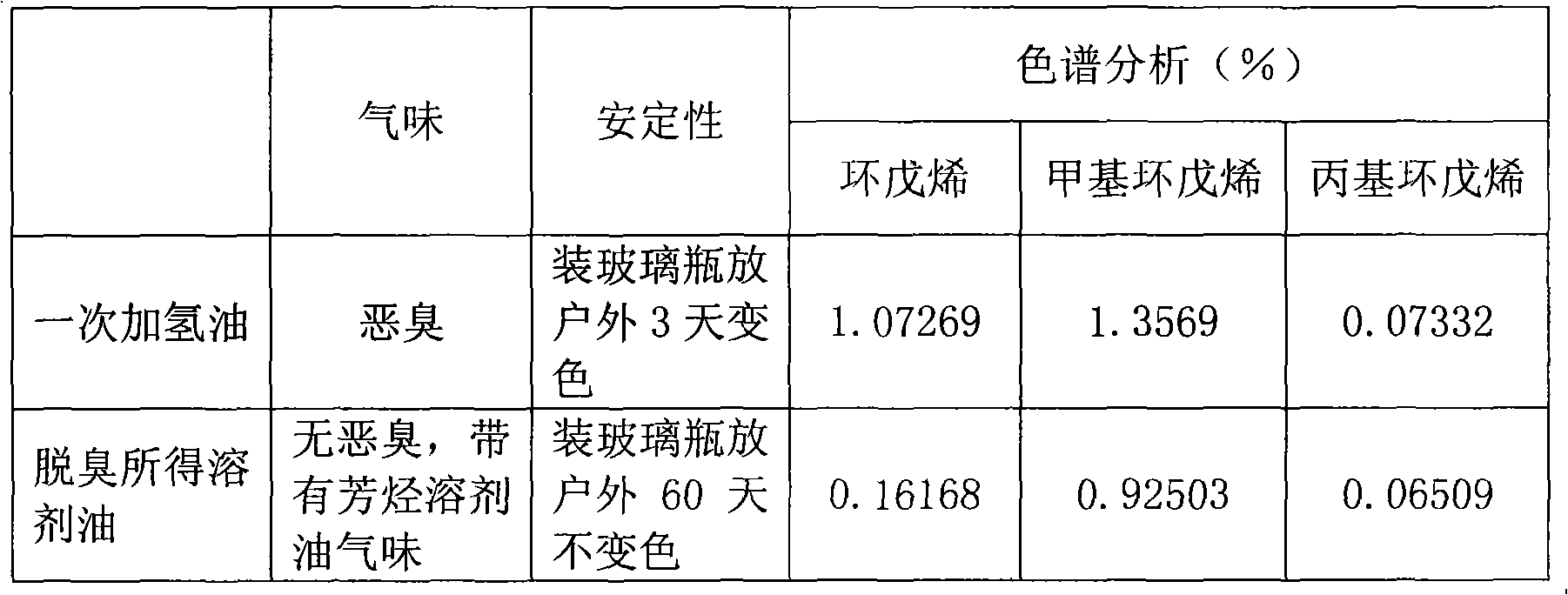

Cracking agent C9 primary hydrotreated oil deodorising method

ActiveCN101649223BImprove the level ofSimple processTreatment with plural serial refining stagesChlorine dioxideRoom temperature

The invention relates to a cracking agent C9 primary hydrotreated oil deodorising method and the method comprises the following steps: a. dissolving acidic activator in primary hydrotreated oil; b. using 3-5 times of water to prepare stabilized chlorine dioxide water solution; c. mixing the obtained solutions in step a and step b, stirring for 0.5-3h, precipitating for 0.1-2h, discharging the precipitate in reaction liquid; d. neutralizing the reaction liquid without precipitate with basic neutralizer to ensure the precipitate to be neutral; e. washing with water 1-2 times, discharging water and obtaining the finished product, wherein the content of the acidic activator is not more than 0.4% of the primary hydrotreated oil, the content of stabilized chlorine dioxide is 0.1-0.5% of primary hydrotreated oil and the above steps are performed at room temperature and normal pressure. The invention has simple process, low cost, no new pollution and good effect.

Owner:广东新华粤石化集团股份公司

A dried apricot processing method

InactiveCN100508786CReduce oxygen contentPrevents enzymatic browningFruit stoningFood preparationInjection airDried apricot

The invention relates to a method for processing dried apricot, wherein it comprises that: washing, removing corn, heating, drying and vacuum packing; the apricot washed and removed corn enters into the air injection heater, impacted by 4. 0-20m / s, 100-200Deg. C and 10-100% humidity air flow for 2-15min, to disinfect enzyme; then enters into the drying box at 50-90Deg. C and 8. 0-15m / s airflow to be dried for 2-15h; then vacuum packing. The inventive dried apricot has high quality, without chemical agent and additive.

Owner:CHINA AGRI UNIV

A kind of pd/cds/toc photocatalyst and its preparation method and application

ActiveCN109876829BImprove thermal stabilityHigh hydrothermal stabilityPhysical/chemical process catalystsWater/sewage treatment by irradiationPhysical chemistryDichlorophenol

Owner:CHANGAN UNIV

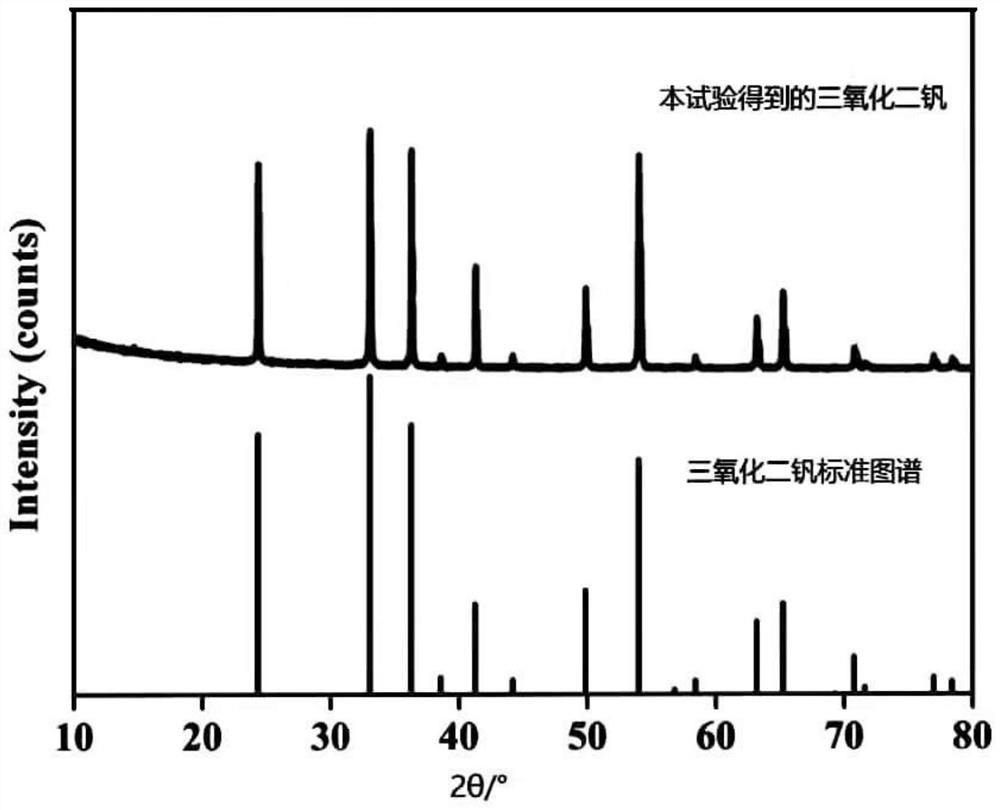

Method for preparing vanadium trioxide by recycling anode electrolyte of invalid vanadium battery

PendingCN112551580ALarge specific surface areaImprove adsorption efficiencyFuel cells disposal/recyclingRegenerative fuel cellsElectrolytic agentElectrical battery

The invention discloses a method for preparing vanadium trioxide by recycling anode electrolyte of an invalid vanadium battery. The method comprises the following steps: a, measuring tetravalent vanadium ion concentration and pentavalent vanadium ion concentration of the anode electrolyte of the invalid vanadium battery; b, adding a carbon-based adsorbent into the electrolyte in the step a, adsorbing, filtering and drying to obtain a vanadium-containing adsorbent; and c, roasting the vanadium-containing adsorbent obtained in the step b under the protection of an inert atmosphere to obtain a vanadium trioxide product. According to the method for preparing the vanadium trioxide by recycling the anode electrolyte of the invalid vanadium battery, the problem of disposal of the electrolyte of the existing invalid vanadium battery can be solved, a high-added-value vanadium trioxide product can be obtained, and the method is simple in process, free of pollution, environmentally friendly and good in application prospect.

Owner:ANSTEEL BEIJING RES INST +1

Clay acrylic surface decorating material and its preparing method

InactiveCN100365082CImprove textureHigh economic valueCoatingsChemical industryPolydimethyl siloxane

The invention is a kind of dual environmental protection building surface ornamenting material produced by using brick powders of grinded waste construction clay bricks as main materials and its producing method. The invention makes clay brick powders as main materials, and is compounded from such chemical industry materials as acrylic acid emulsion, sodium hexametaphosphate, sodium benzoate, glycol, trimethylene glycol, polydimethyl siloxanes, methylcellulose and titanium oxide powder as per certain proportion. The invention has simple technics, convenient and sanitary construction, and can be used both in upscale wall surface and surfaces of column, tablet and board. After ornamented, it has elegant and vivid brick wall style, especially suitably used for outer ornament and repair of building wall surfaces whose outer walls need brick wall structures.

Owner:TONGJI UNIV

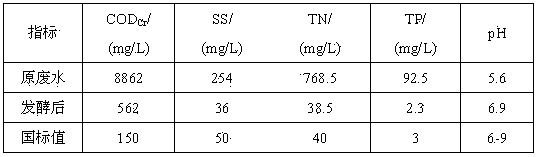

Method for preparing microbial flocculant form potato starch wastewater as raw material

InactiveCN103045649BGood environmental benefitsReduce CODMicroorganism based processesFermentationBiotechnologyFlocculation

Owner:GANSU AGRI UNIV

Refining production method of glycerin

InactiveCN101759526BLess investmentSave energyIon-exchange column/bed processesHydroxy compound separation/purificationTrans esterificationBiodiesel

The invention provides a refining production method of crude glycerin. Byproducts of grease ester exchange or hydrolyzation are used as ingredients, and byproducts of biodiesel can also be used as ingredients. The method comprises the following steps: acidizing treatment, decolourization, alkali return for neutralization, concentration for salt removal, ion exchange and concentration treatment, wherein the ion exchange step comprises the substep of sequentially using cations, anions, cations, anions and zwitterions to exchange resin posts in a mixed way, the operation temperature of the resinposts is controlled between 40 and 60 DEG C, the flow rate is 15 mL / min, and finally, the pure glycerin solution is collected. The process of the invention has the advantages of simple operation condition, low temperature, little pollution and high yield, and can avoid the deterioration of the glycerin at the high temperature, the yield is higher than 97 percent, and the product purity is higher than 99.2 percent. The invention also provides a multiplex mixed type anion-cation exchange resin post combination device applicable to the method.

Owner:HUNAN ACAD OF FORESTRY

Waterproof glue for external wall ceramic tile

InactiveCN101735750BExcellent physical and chemical propertiesImprove the decorative effectAdhesivesEmulsionPreservative

The invention discloses a waterproof glue for external wall ceramic tile, which is formed by formulating acrylic emulsion, ethylene glycol, film forming auxiliary (dodecyl ester), alkali swelling thickener, antiseptic and defoaming agent, the waterproof glue has the advantages of being waterproof, joint-filling, transparent, rich in elasticity, environmentally-friendly, bright and clean, simple and convenient in applying, etc., and is free from toxicity, odor and new pollution even in case of the long-term use thereof and is also age resisting, therefore, the waterproof glue for external wallceramic tile is an ideal product for environmental protection.

Owner:康信勇

Cracking agent C9 primary hydrotreated oil deodorising method

ActiveCN101649223AImprove the level ofSimple processTreatment with plural serial refining stagesChlorine dioxideRoom temperature

The invention relates to a cracking agent C9 primary hydrotreated oil deodorising method and the method comprises the following steps: a. dissolving acidic activator in primary hydrotreated oil; b. using 3-5 times of water to prepare stabilized chlorine dioxide water solution; c. mixing the obtained solutions in step a and step b, stirring for 0.5-3h, precipitating for 0.1-2h, discharging reactionliquid, obtaining precipitate; d. neutralizing the precipitate with basic neutralizer to ensure the precipitate to be neutral; e. washing with water 1-2 times, discharging water and obtaining the finished product, wherein the content of the acidic activator is not more than 0.4% of the primary hydrotreated oil, the content of stabilized chlorine dioxide is 0.1-0.5% of primary hydrotreated oil andthe above steps are performed at room temperature and normal pressure. The invention has simple process, low cost, no new pollution and good effect.

Owner:广东新华粤石化集团股份公司

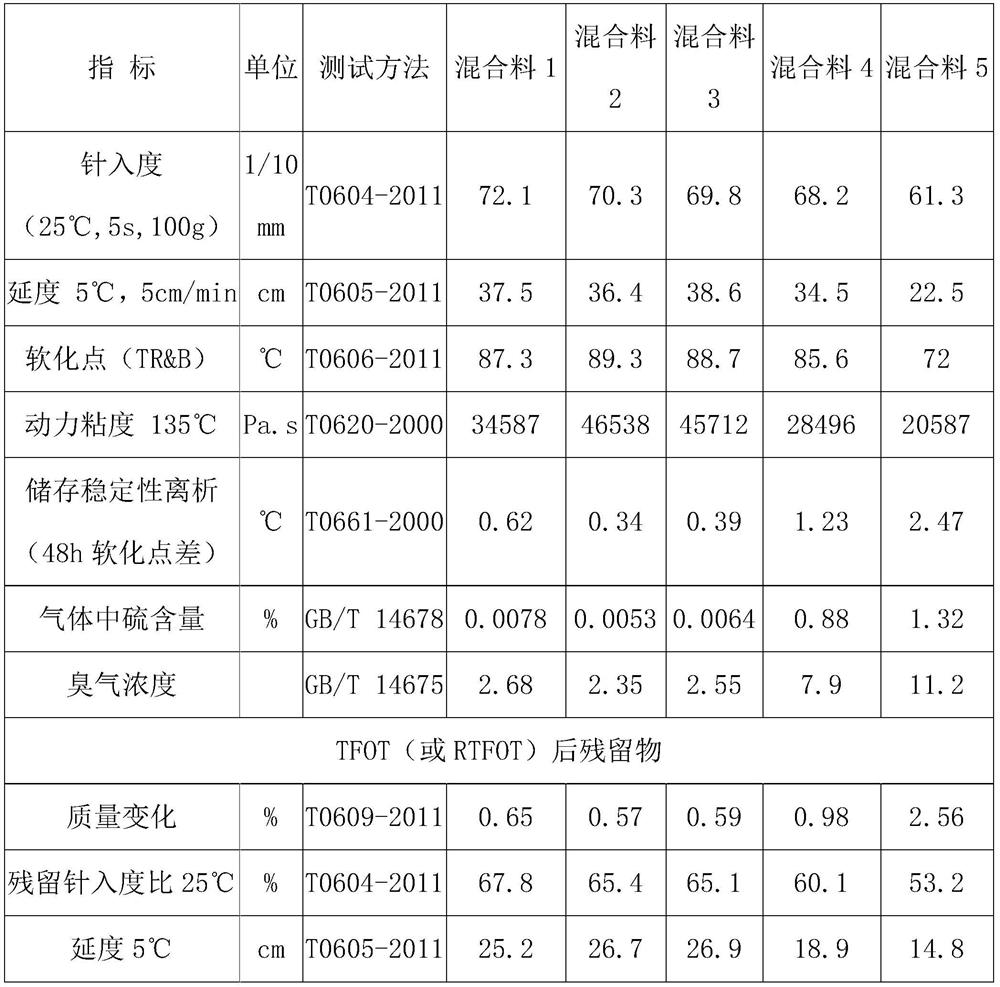

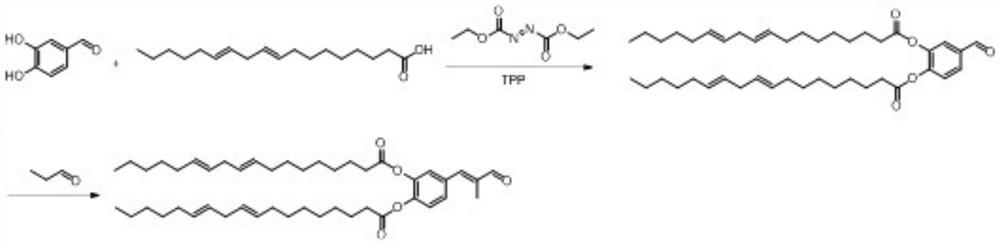

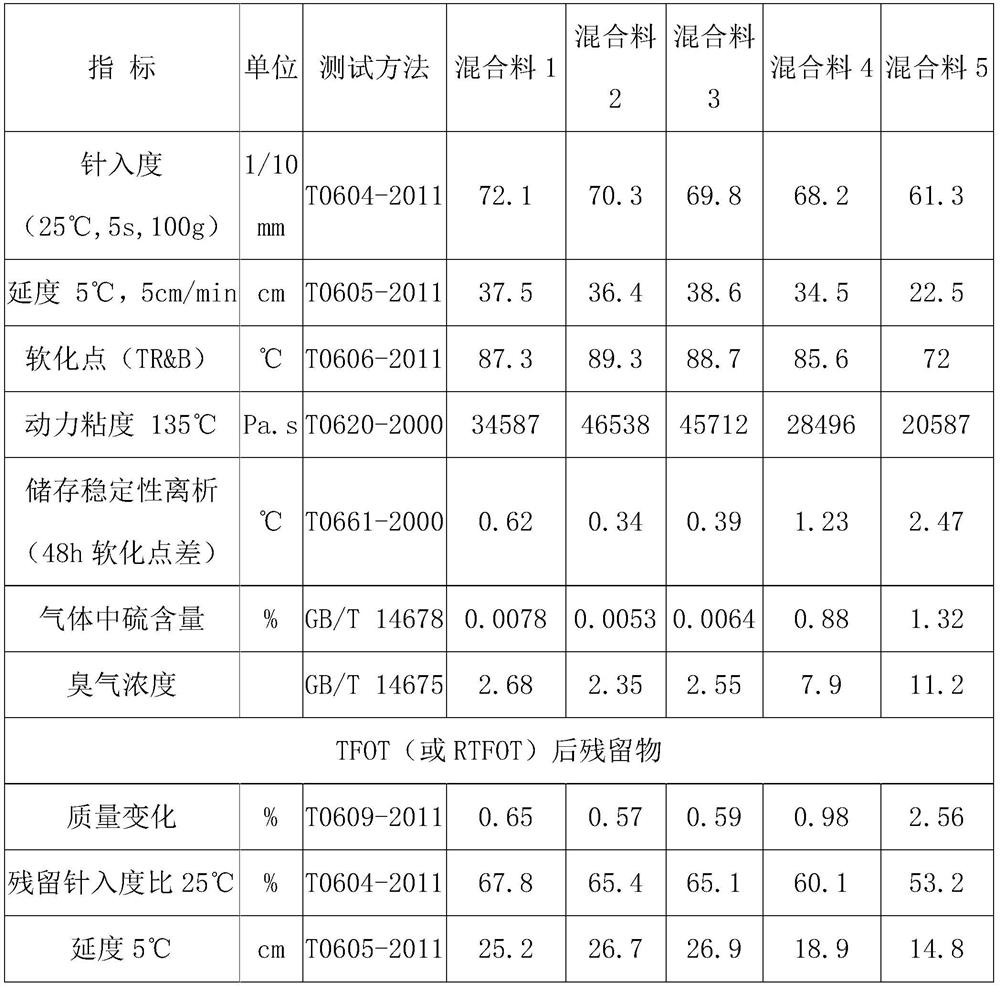

A kind of preparation method and application of bio-based deodorant

Owner:山东高速集团有限公司创新研究院 +2

An electrokinetic-permeable reactive wall joint remediation method for heavy metal-contaminated soil

ActiveCN110369485BRepair fieldEasy to operateContaminated soil reclamationElectrokinetic remediationMontmorillonite

The invention belongs to the technical field of remediation of polluted soil, and in particular relates to a joint repair method of electrodynamic-permeable reaction walls for heavy metal polluted soil, in which a positive electrolytic cell and a negative electrolytic cell are arranged within a certain distance, and an electrolytic cell is arranged at a place where heavy metals of pollutants are enriched. The permeable reaction wall is connected to the power supply to perform electrodynamic restoration of the polluted soil. The permeable reaction wall is filled with adsorption materials, and the adsorption material is a three-layer coating structure: the innermost core layer is reduced iron and biological bacteria agent, The core layer is wrapped with an iron-loaded modified montmorillonite middle layer, and the middle layer is wrapped with a biochar outer layer. In the joint repair method of the present invention, the adsorption material used in the permeable reaction wall is a three-layer coating structure, and the zero-valent iron and biological bacteria agent with unstable performance are coated, which can effectively improve its stability and utilization rate, and has the advantages of High practical value and broad application prospects.

Owner:迪天环境技术南京股份有限公司

A kind of pd/cds/toc photocatalyst and its preparation method and application

ActiveCN109939697BExpand the photoresponse rangeIncrease profitWater/sewage treatment by irradiationWater contaminantsWastewaterPollution

The Pd / CdS / TOC photocatalyst and its preparation method and application disclosed in the present invention use TOC as a loading object, and CdS is loaded on TOC to prepare a CdS / TOC photocatalyst. On the basis of the CdS / TOC photocatalyst, further Pd was loaded to obtain Pd / CdS / TOC photocatalyst. The photocatalysts prepared by the present invention are all green and environment-friendly materials, will not produce new pollution after degradation, have high degradation efficiency, can adapt to a wide range of environments, can be applied to wastewater treatment, have high efficiency in degrading 2,4-dichlorophenol, and are useful for popularization and application. Great advantage.

Owner:CHANGAN UNIV

Architectural joint filling material made from waste polyurethane and waste fiber, and its preparation method

InactiveCN100365058CHigh economic valueGood physical and chemical propertiesBuilding insulationsFiberPolypropylene

The present invention belongs to the filed of building material technology, in particular, it relates to a building joint-filling material prepared by utilizing waste polyurethane and waste fibre and its preparation method. It is made up by using waste polyurethane and waste polypropylene fibre as aggregate, and mixing them with chemical raw materials of acrylic acid emulsion, sodium hexametaphosphate, sodium benzoate, ethylene glycol, propylene glycol, polydimethylsiloxane, methyl cellulose, calcium carbonate and colouring agent according to a certain mixing ratio.

Owner:TONGJI UNIV

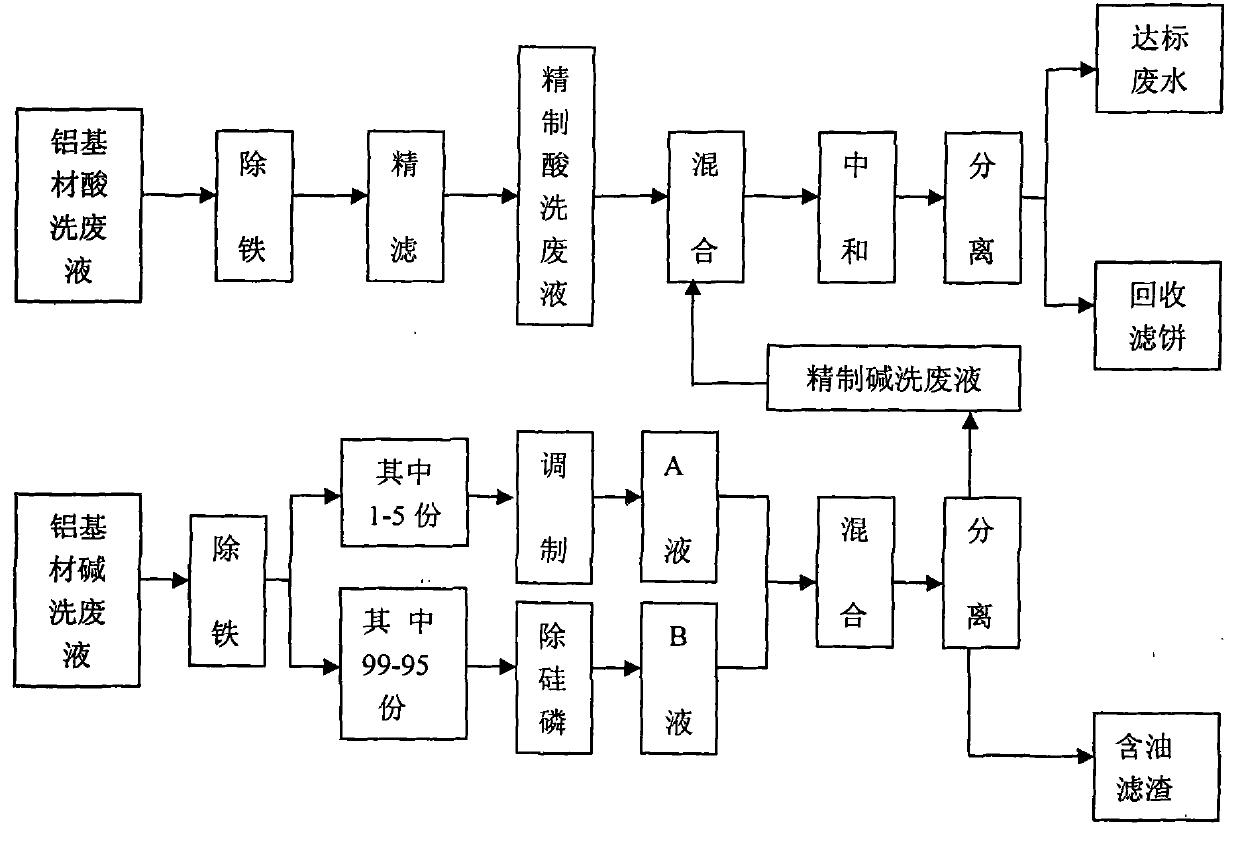

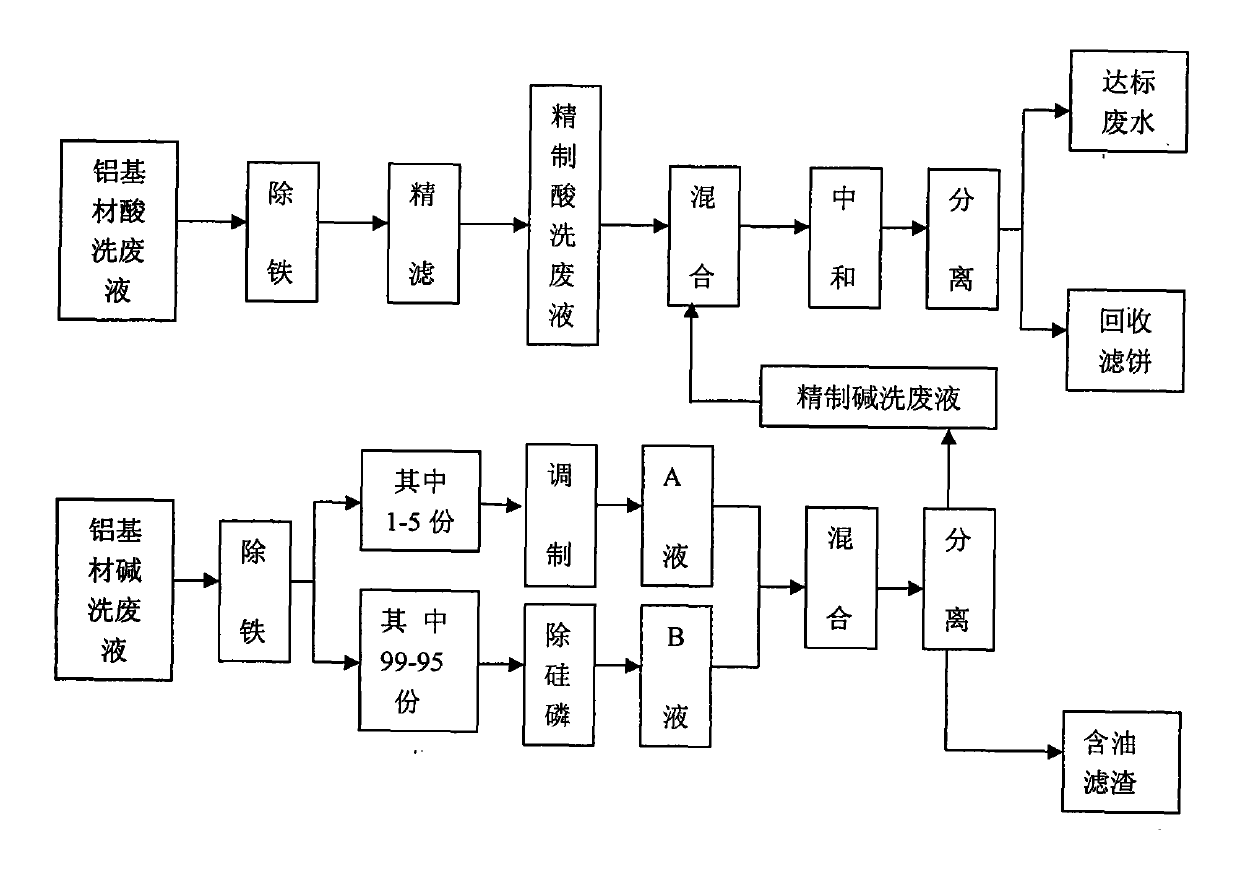

Treatment technology of acid washing and alkaline washing waste liquid of aluminum substrate

ActiveCN101624243BImprove filtering effectExtended service lifeSolid fuelsWaste based fuelSide productChemistry

The invention relates to a technology of industrial waste liquid treatment, and provides a treatment technology of acid washing and alkaline washing waste liquid of aluminum substrate. The treatment technology is mainly characterized in that oil removal, iron removal and phosphorus and silica removal pretreatments are respectively carried out on acid washing waste liquid and alkaline washing waste liquid, and the acid washing waste liquid and the alkaline washing waste liquid are mixed, neutralized and separated, oily filter residue can be used as fuel, filter cakes can be recycled, and the waste water discharged reaches the standard. The treatment technology can perform smooth treatment to a large amount of acid washing and caustic washing waste liquid of aluminum substrate, can not cause additional pollution, can recycle side products, and solves the technical problem in the field at home and abroad for a long time, and a pilot-scale test shows that the design is reasonable, the technology is easy to be implemented, and the technology has great social, environmental protection and economic benefits.

Owner:申明乐 +1

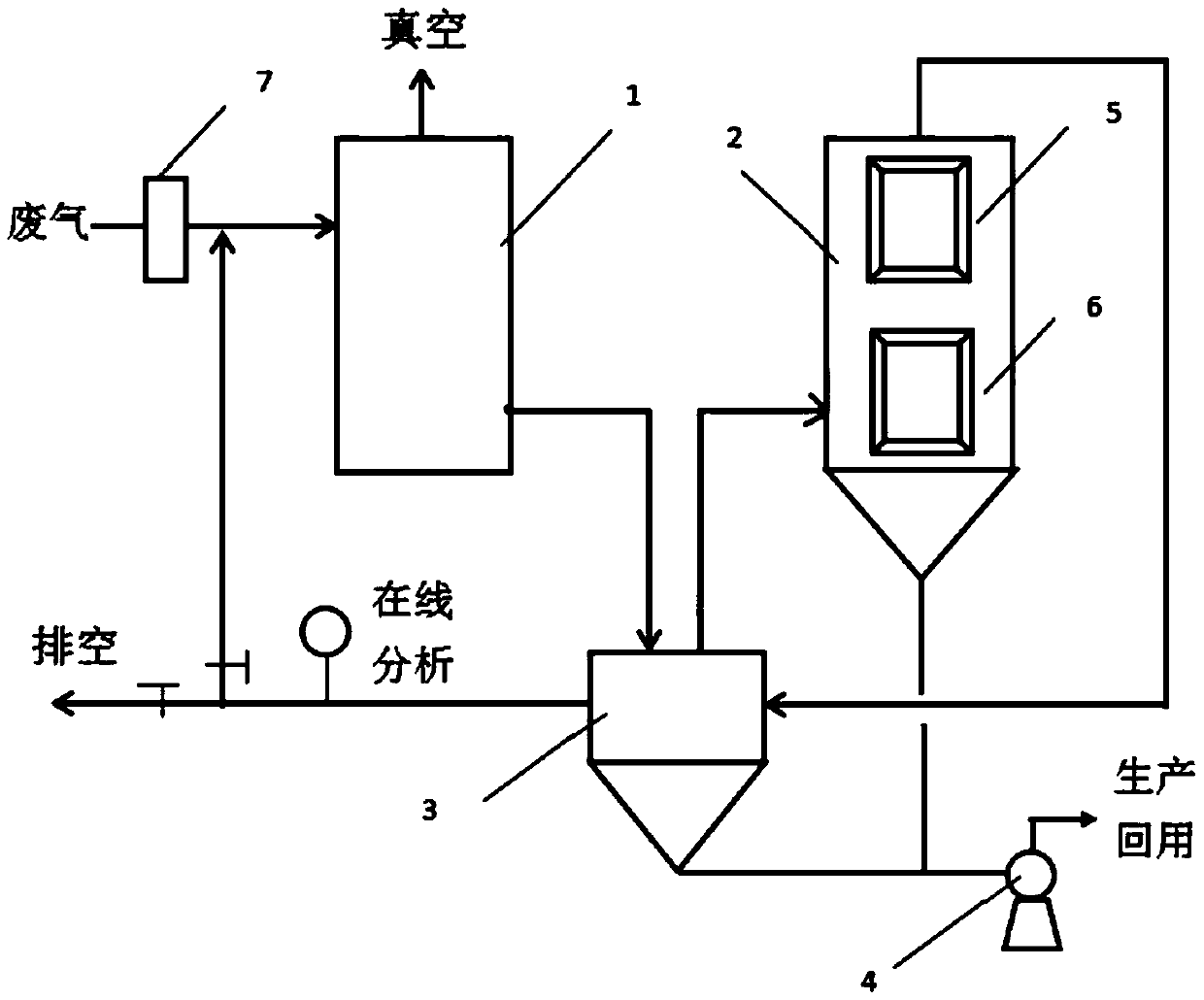

A device and method for concentration, recovery and treatment of organic waste gas

ActiveCN107042057BNo risk of explosionOperational securityGas treatmentDispersed particle filtrationWater vaporExhaust fumes

The invention relates to a treatment device and method for concentrating and recovering organic waste gas. The method comprises the steps of (1) feeding the organic waste gas into a membrane assembly through a dust remover; (2) keeping the membrane assembly in vacuum and separating out nitrogen, oxygen and water vapor to obtain the concentrated organic waste gas; (3) pre-cooling the concentrated organic waste gas through an exhaust gas heat exchanger, and feeding the concentrated organic waste gas into a cryogenic catcher; and (4) condensing organic matter steam in the cryogenic catcher, reusing condensate to a production system, carrying out heat exchange and online analysis on non-condensable gas through the exhaust gas heat exchanger, evacuating if the exhaust gas is qualified, and if the exhaust gas is not qualified, returning the exhaust gas to an inlet of the membrane assembly in cycle for secondary treatment until the exhaust gas is qualified. The invention provides a treatment method for the organic waste gas, which is safe in operation and free of new pollution, the application range of the organic matter content is wide, and the organic matters in the waste gas can be recycled.

Owner:WUHAN UNIV OF TECH

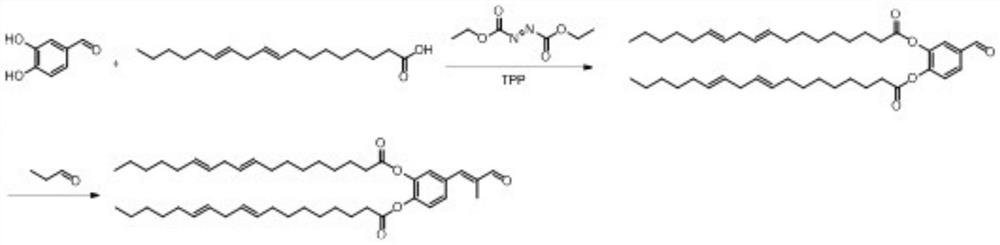

Preparation method and application of bio-based deodorant

The invention relates to the technical field of road asphalt, in particular to a bio-based deodorant as well as a preparation method and application thereof. The bio-based deodorant is prepared from 40-60 parts of 3, 4-dilinoleyloxy-a-methyl benzene acrolein, 40-60 parts of nano white carbon black, 0.3-0.5 part of an antioxidant and 1-3 parts of polyethylene wax. In the use process, the bio-based deodorant can form a ficus base substance with amino in asphalt; and hydrogen sulfide, mercaptan and the like generated in a stabilizer development process form stable thioacetal, so that toxic gas does not overflow any more, and the use pollution is reduced. The synthesis raw materials are all from natural substances, for example, 3, 4-dihydroxybenzaldehyde is extracted from roots of labiatae plant salvia miltiorrhiza, and linoleic acid can be extracted from various oil crops. The synthesis method is green, environment-friendly and pollution-free; and the synthetic product is degradable and can be degraded by bacterial microorganisms after the pavement reaches the service life. The synthetic raw materials have special plant fragrance, and can relieve the discomfort of operators caused by peculiar smell generated in the asphalt mixing process.

Owner:山东高速集团有限公司创新研究院 +2

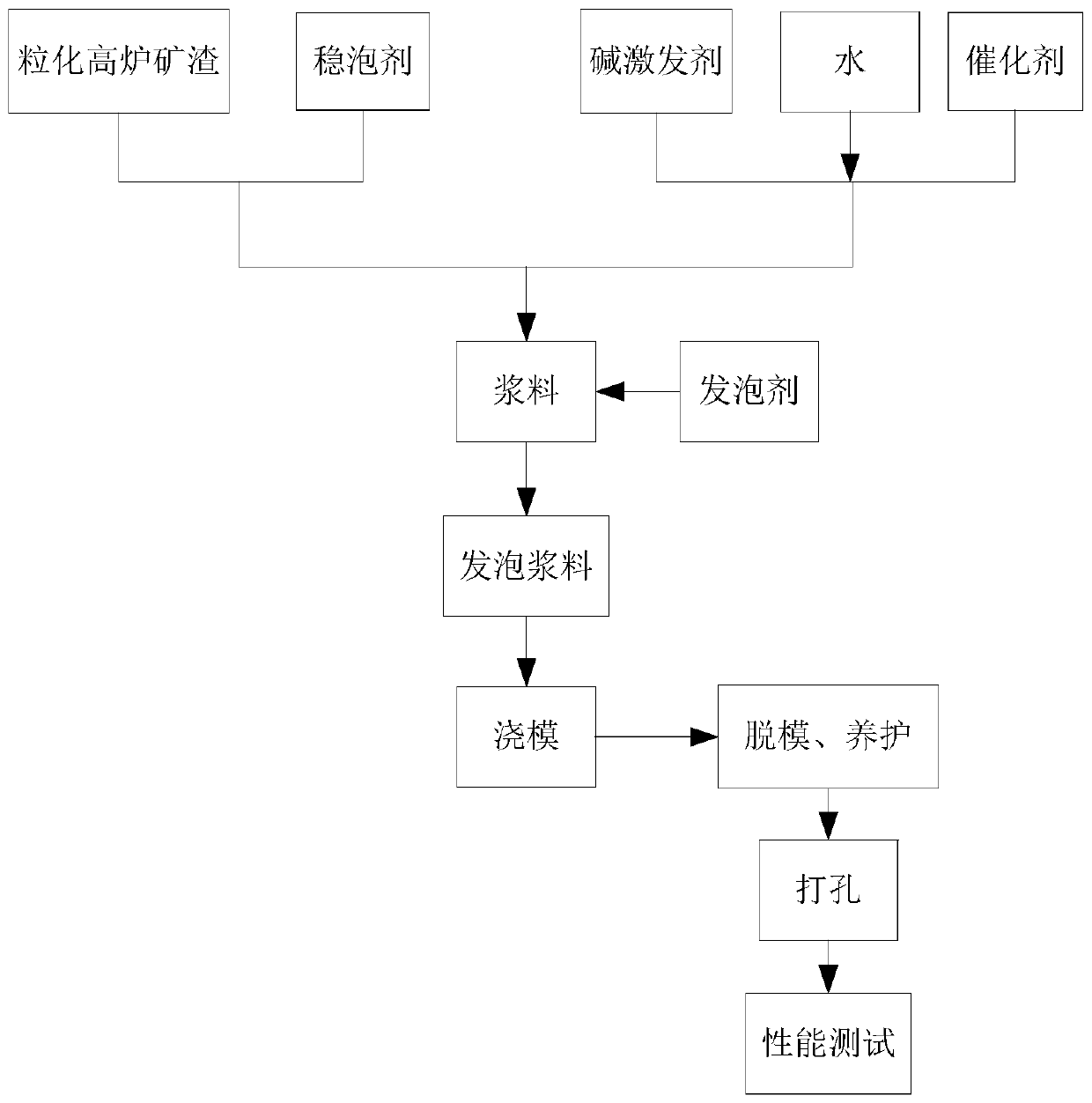

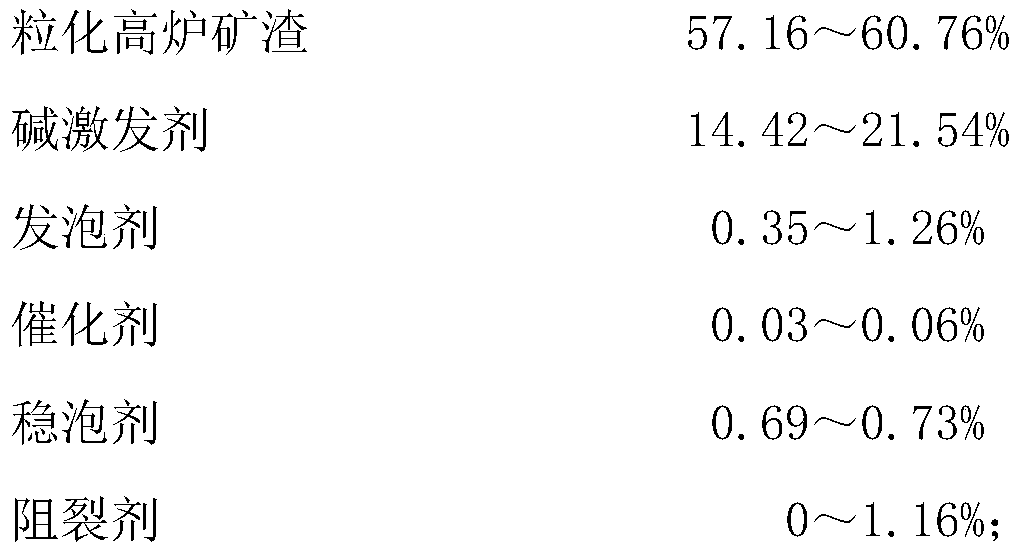

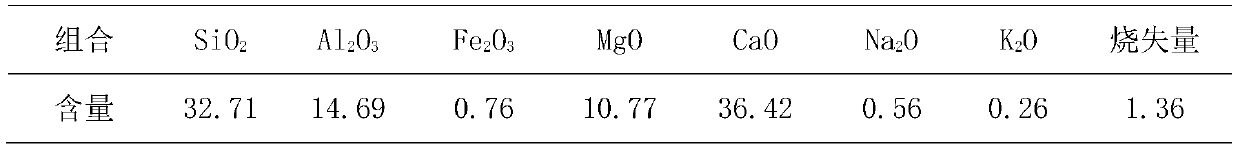

A kind of alkali slag foamed concrete sound-absorbing material and its preparation method

ActiveCN106927770BReduce pollutionEmission reductionCeramicwareEnvironmental resistanceFoam concrete

The invention discloses an alkali slag foamed concrete sound absorption material and a preparation method thereof. The sound absorption material comprises granulated blast furnace slag, an alkali activator, a foaming agent, a catalyst, a foam stabilizer and a crack arresting agent, wherein the component of an alkali slag gel is blast furnace slag, the alkali activator is one kind or two kinds of combinations of water and sodium hydroxide, the foaming agent is hydrogen peroxide, the catalyst is potassium permanganate, the foam stabilizer is calcium stearate, and the crack arresting agent is one kind or two kinds of combinations of polypropylene fiber and polyvinyl alcohol fiber; in addition, water with a certain weight percentage is added in producing. According to the method, the obtained alkali slag foamed concrete sound absorption material has the advantages of green environmental protection, low cost, and high durability. The preparation method has the advantages of low energy consumption and environmental friendliness.

Owner:CHONGQING UNIV

Method for recovering lithium and potassium from high-lithium-potassium anode carbon slag or high-lithium-potassium electrolyte

ActiveCN111321302BFull recoveryHigh recovery rateProcess efficiency improvementLithiumPhysical chemistry

Owner:SHENYANG BEIYE METALLURGIGAL TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com