Cracking agent C9 primary hydrotreated oil deodorising method

A hydrogenation oil and deodorization technology, which is only applied in the direction of multi-stage series refining process, can solve the problems of not meeting the quality requirements of solvent oil, odor, instability, etc., and achieve low cost, good effect, and no new The effect of increasing pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

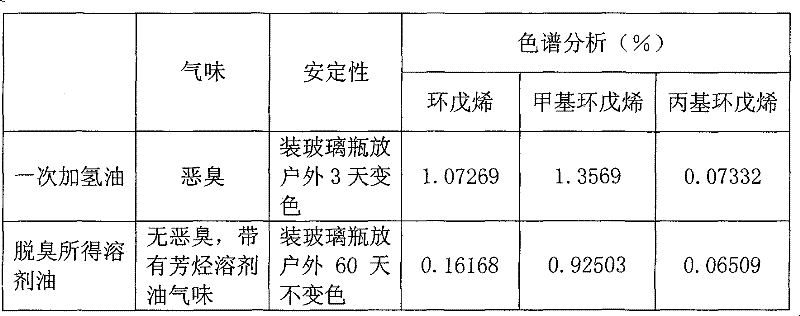

[0022] In 1000 grams of primary hydrogenated oil, add 2 grams of activator citric acid, stir and dissolve, then add binary solid stable chlorine dioxide that accounts for 0.25% of the weight of primary hydrogenated oil and is made of 4 times the weight of water solution, stirred for 1 hour, settled for 25 minutes and drained the precipitate in the reaction solution; the reaction solution was neutralized to neutrality with alkaline neutralizing agent sodium hydroxide after the precipitate was discharged; then 300 grams of water was added for washing until The oil product is neutral, and it can be obtained after draining clean water. The above steps are all carried out under normal temperature and pressure. It is distilled to obtain the aromatic solvent oil that meets the market demand.

[0023] Comparison of deodorized solvent oil obtained in the present invention with primary hydrogenated oil without deodorization:

[0024]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com