Refining production method of glycerin

A production method and technology of glycerol, applied in the field of glycerol, can solve the problems of difficulty in removing residues, high energy consumption, affecting yield and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

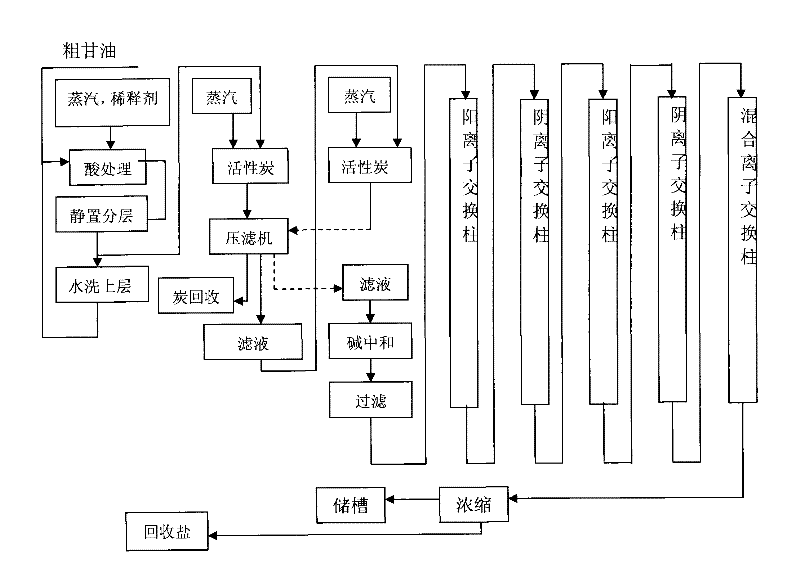

Image

Examples

Embodiment 1

[0041] The refining of embodiment 1 palm oil by-product glycerol

[0042] Get 5Kg palm oil by-product crude glycerol (through centrifugation, concentration is 80%), add 50% dilute sulfuric acid till system solution pH=3~4, remove upper layer fatty acid, can repeat this step if necessary. Under the conditions of acidity (pH=3) and 90°C, activated carbon was used twice for decolorization, the addition amount was 100g and 8g respectively, stirred for 20-30min, and filtered under heat; calcium hydroxide emulsion (that is, calcium hydroxide dissolved in water) to adjust the pH until the solution is adjusted to pH=7, remove excess water, add methanol equivalent to about 1% of the mass of crude glycerin, dilute and filter for desalination. Then quickly evaporate to remove methanol, and dilute the filtered glycerin to 40% with deionized water, and enter the strongly acidic styrene-based cation exchange resin type 732, D201 type anion-exchange resin, and strongly acidic styrene-based c...

Embodiment 2

[0044] The refining of embodiment 2 waste oil by-product glycerin

[0045] Get 20Kg of gutter oil by-product crude glycerin (through static stratification, concentration is about 40%), at first carry out acidification until solution pH=3~4 (preferably 4), remove fatty acid (if residual fatty acid is more, can repeat above step operation). The remaining glycerin was decolorized twice with activated carbon, and the dosage was equivalent to 2% and 0.2% of the mass of crude glycerin respectively. Calcium hydroxide is then used to neutralize and adjust to pH=7 of the whole solution. The concentration desalination and ion exchange steps are the same as in Example 1, wherein the column temperature is controlled at 60° C., and the feed rate is 15 mL / min. Concentrate for final storage. A total of 7.768Kg of refined glycerin was obtained, and the yield was over 97%.

[0046] Measuring indicators: Refined glycerin has no peculiar smell, color (Hazen) ≤ 10 Hazen, density ≥ 1.2572, chl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com