A device and method for concentration, recovery and treatment of organic waste gas

A technology for organic waste gas and tail gas, applied in separation methods, gas treatment, chemical instruments and methods, etc., can solve the problems of destroying the structure of organic components, unable to operate stably for a long time, and consuming natural gas, and achieve the effect of safe operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

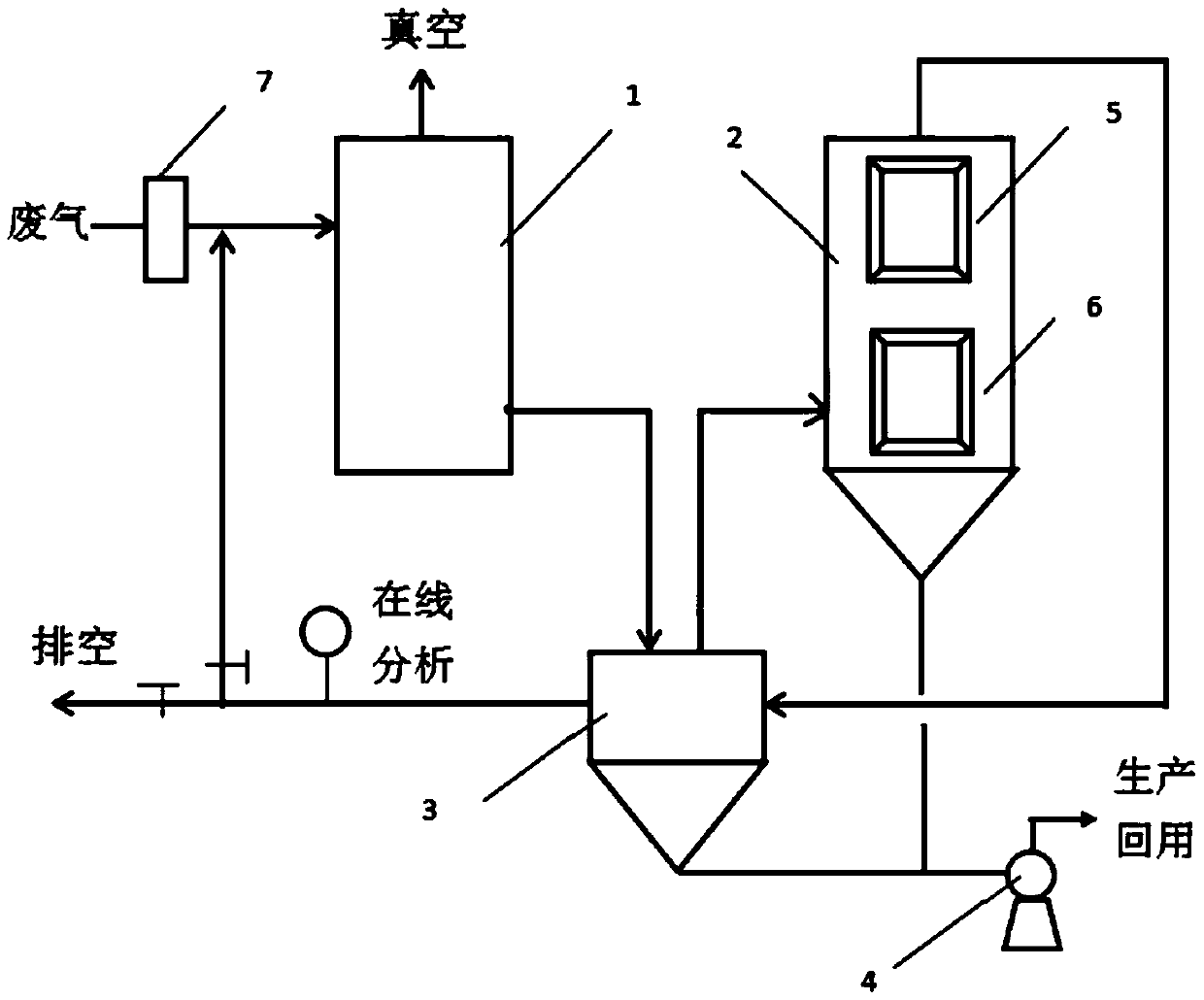

[0026] This embodiment provides an organic waste gas concentration recovery treatment device, which includes a dust collector 7, a membrane module 1, a tail gas heat exchanger 3, and a cryogenic trap 2. The organic waste gas passes through the dust collector 7 to the membrane module 1. The concentrated organic waste gas after the membrane module 1 treatment enters the exhaust gas heat exchanger 3, and the organic waste gas discharged from the exhaust gas heat exchanger 3 enters the cryogenic trap 2, the cryogenic trap The condensate of 2 is recovered for use in the production system, and the non-condensable gas discharged from the cryogenic trap 2 enters the exhaust gas heat exchanger 3 for heat exchange and online analysis.

[0027] The main components of organic waste gas are: formaldehyde, benzene, toluene, xylene and other benzene series, acetone and methyl ethyl ketone, ethyl acetate, oil, furfural, styrene, acrylic acid, resin, additives, paint mist, and some organic hydroca...

Embodiment 2

[0036] The organic waste gas concentration, recovery and treatment device of this embodiment is roughly the same as that of Embodiment 1. The difference is that the membrane module of this embodiment is composed of two sets of membrane modules in series, and each module is composed of 250 NaA molecular sieve membrane tubes. Tube diameter 12mm, length 1000mm, total membrane area 20m 2 .

[0037] This embodiment also provides a method for concentrated recovery and treatment of organic waste gas, which includes the following steps:

[0038] (1) The organic waste gas enters the membrane module 1 through the dust collector 7 with a flow rate of 5m 3 / h, the organic component is acetone, and the acetone content is 0.52vol%;

[0039] (2) The exhaust gas flows through the membrane module to separate most of nitrogen, oxygen and water vapor to obtain concentrated organic waste gas; the membrane module maintains a vacuum of -95kPa, and the vacuum exhaust acetone content is 0.004vol%;

[0040] (...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com