A kind of alkali slag foamed concrete sound-absorbing material and its preparation method

A foamed concrete and sound-absorbing material technology, applied in the field of building materials, can solve the problems of high production energy consumption and complex preparation process, and achieve the effects of high template utilization rate, simple process and wide source.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

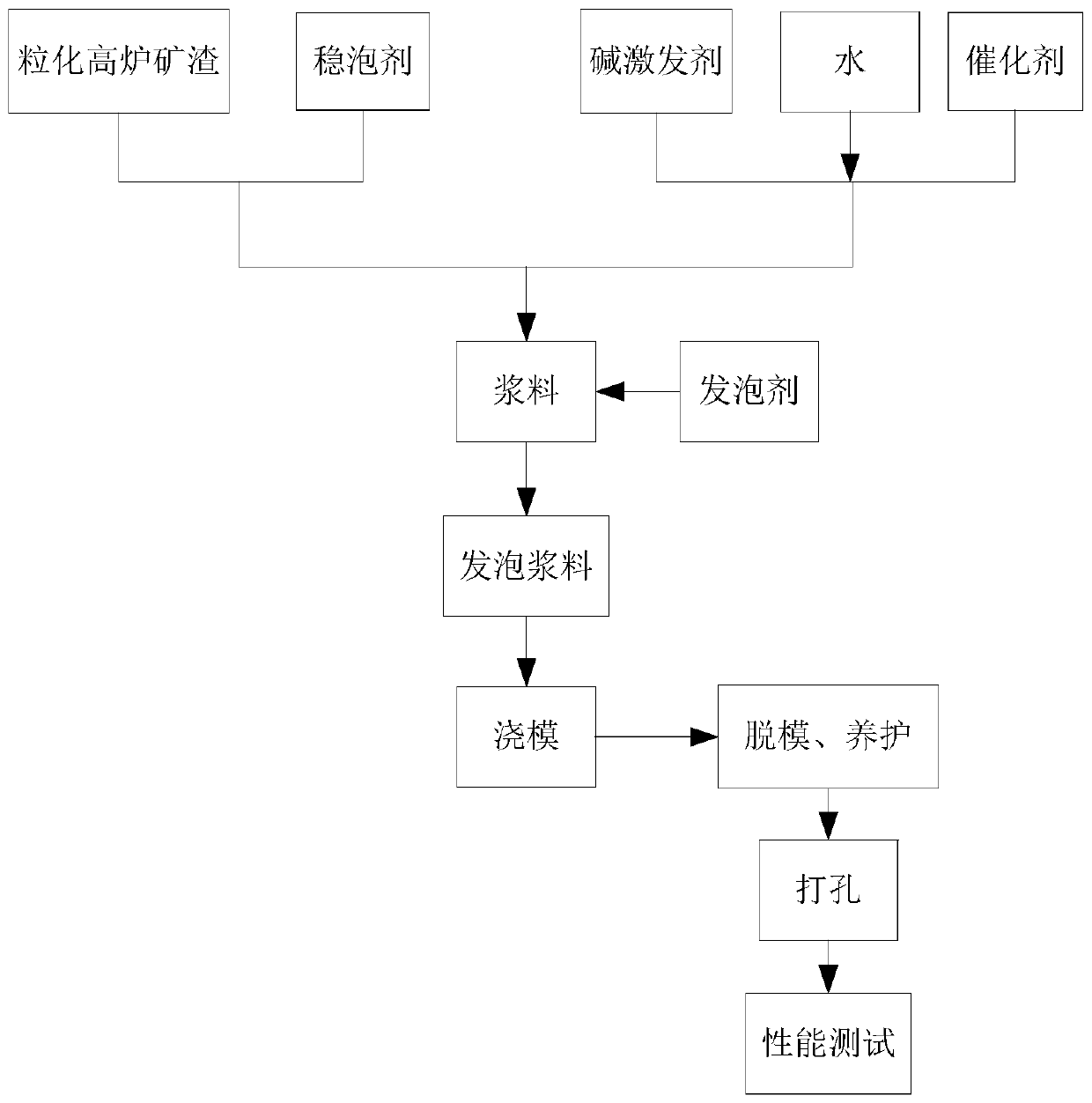

Method used

Image

Examples

Embodiment 1

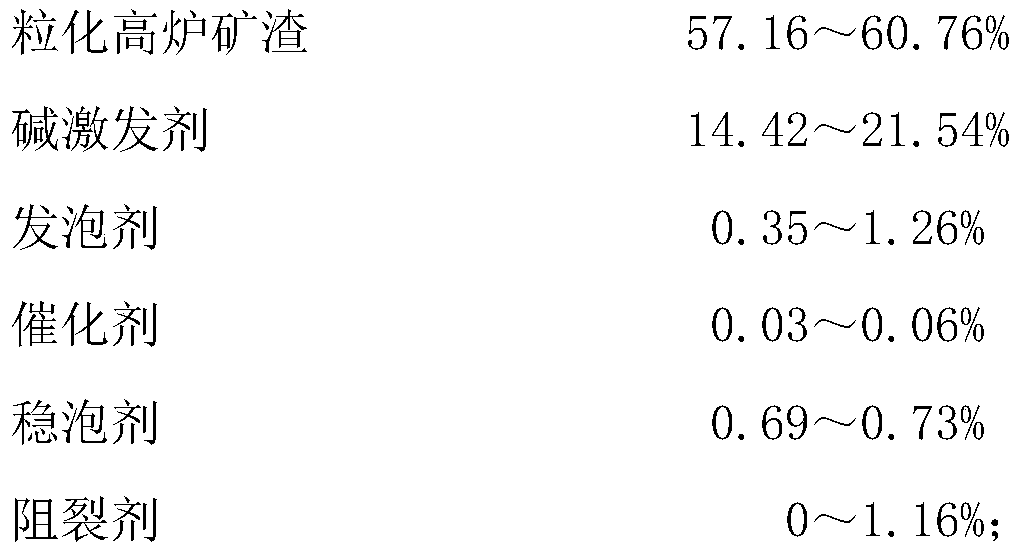

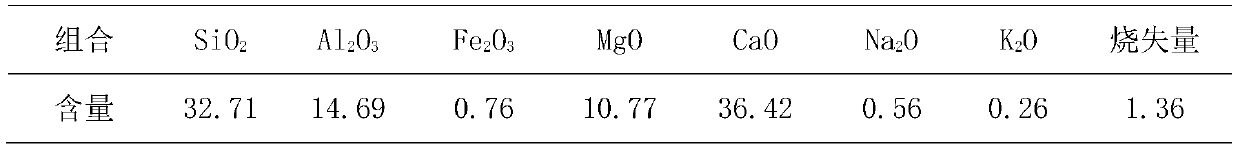

[0026] An alkali slag foamed concrete sound-absorbing material, wherein the components are calculated by weight percentage: granulated blast furnace slag 60.76%, water glass 14.7%, water 23.28%, hydrogen peroxide 0.36%, potassium permanganate 0.06%, stearin Calcium acid 0.73%, polypropylene fiber 0.11%;

[0027] Wherein, the bulk density of the alkali slag foamed concrete is 894kg / m 3 .

[0028] A preparation method of alkali slag foamed concrete sound-absorbing material, comprising the following steps:

[0029] S1. Pour the granulated blast furnace slag and calcium stearate powder into the mixer according to the proportion and stir for 3 minutes, and mix evenly;

[0030]S2. Mix water glass, potassium permanganate and water according to the proportioning ratio, and stir to form a solution, then pour the obtained solution into the powder obtained in step S1 and fully stir for 45 seconds to make a slurry;

[0031] S3. Mixing and stirring the polypropylene fiber and the slurry...

Embodiment 2

[0035] An alkali slag foamed concrete sound-absorbing material, wherein the components are calculated by weight percentage: 59.39% of granulated blast furnace slag, 18.1% of water glass and sodium hydroxide, 20.94% of water, 0.36% of hydrogen peroxide, and 0.06% of potassium permanganate %, calcium stearate 0.71%, polypropylene fiber 0.44%;

[0036] Wherein, the weight ratio of the water glass and sodium hydroxide composition is water glass: sodium hydroxide=1:8, and the bulk density of the alkali slag foamed concrete is 928kg / m 3 .

[0037] A preparation method of alkali slag foamed concrete sound-absorbing material, comprising the following steps:

[0038] S1. Pour the granulated blast furnace slag and calcium stearate powder into the mixer according to the proportion and stir for 3 minutes, and mix evenly;

[0039] S2, mixing water glass, sodium hydroxide, potassium permanganate and water according to the proportion, stirring evenly to form a solution, then pouring the ob...

Embodiment 3

[0044] An alkali slag foamed concrete sound-absorbing material, wherein the components are calculated by weight percentage: 58.88% of granulated blast furnace slag, 18.46% of sodium hydroxide, 21.53% of water, 0.35% of hydrogen peroxide, 0.06% of potassium permanganate, hard Calcium fatty acid 0.71%, polypropylene fiber 0.01%;

[0045] Wherein, the bulk density of the alkali slag foamed concrete is 928kg / m 3 .

[0046] A preparation method of alkali slag foamed concrete sound-absorbing material, comprising the following steps:

[0047] S1. Pour the granulated blast furnace slag and calcium stearate powder into the mixer according to the proportion and stir for 3 minutes, and mix evenly;

[0048] S2, mixing sodium hydroxide, potassium permanganate and water according to the proportioning ratio, stirring evenly to form a solution, then pouring the obtained solution into the powder obtained in step S1 and fully stirring for 45 seconds to make a slurry;

[0049] S3. Mixing and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com