Method for preparing vanadium trioxide by recycling anode electrolyte of invalid vanadium battery

A positive electrolyte, vanadium trioxide technology, applied in battery recycling, fuel cell disposal/recycling, vanadium oxide, etc., can solve the problems of waste water generation, complex recycling process, exhaust gas pollution, etc., to reduce production costs, adsorption High efficiency and resource saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

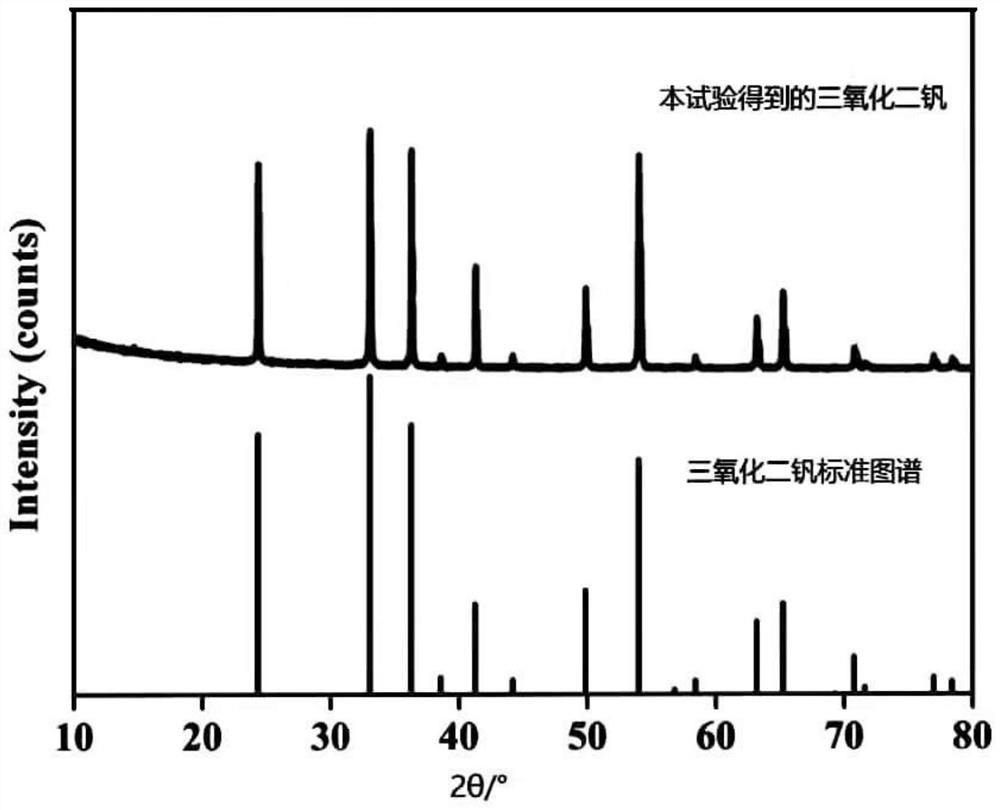

Embodiment 1

[0042] Measure 1L of invalid vanadium battery positive electrode electrolyte, adopt potentiometric titration to measure the concentration of vanadium ions, wherein the concentration of pentavalent vanadium ions is 1.2mol / L, and the concentration of tetravalent vanadium ions is 0.4mol / L, add activated carbon 9.6g ( That is, 0.8 moles), the ratio of activated carbon to the total molar amount of tetravalent vanadium ions and pentavalent vanadium ions in the electrolyte is 0.5:1, shake at 10°C for 4 hours and then filter. The filtered activated carbon was dried at 60° C. for 90 minutes to obtain a dry vanadium-containing adsorbent. Put the dry vanadium-containing adsorbent in a muffle furnace, blow in nitrogen, heat to 500°C, and keep it warm for 1 hour; cool down to room temperature with the furnace, take it out of the furnace, grind it finely, and obtain the vanadium trioxide product. The phase composition in the product is identified as vanadium trioxide by X-ray diffraction me...

Embodiment 2

[0045] Measure 2.5L of the positive electrode electrolyte of the invalid vanadium battery, and use the potentiometric titration method to measure the concentration of vanadium ions. After testing, the concentration of pentavalent vanadium ions is 0.8mol / L, and the concentration of tetravalent vanadium ions is 0.7mol / L. Add 22.5g of carbon black (that is, 1.875 moles), the ratio of carbon black to the total molar mass of tetravalent vanadium ions and pentavalent vanadium ions in the electrolyte is 0.5:1, stir at 40°C for 2 hours and then filter. The filtered carbon black was dried at 90° C. for 60 minutes to obtain a dry vanadium-containing adsorbent. Put the dry vanadium-containing adsorbent in a muffle furnace, feed it with argon, heat it to 650°C, and keep it warm for 2 hours; cool it to room temperature with the furnace, take it out of the furnace, grind it finely, and get the vanadium trioxide product. Use ammonium ferrous sulfate-titration method (GB / T 20567-2006) to meas...

Embodiment 3

[0048] Measure 0.5L of the positive electrode electrolyte of the invalid vanadium battery, and use the potentiometric titration method to measure the concentration of vanadium ions. After testing, the concentration of pentavalent vanadium ions is 0.3mol / L, and the concentration of tetravalent vanadium ions is 1.4mol / L. Tube 5.1g (that is, 0.425 moles), the ratio of multi-walled carbon nanotubes to the total molar amount of tetravalent vanadium ions and pentavalent vanadium ions in the electrolyte is 0.5:1, stirred at 30°C for 3 hours and then filtered. The filtered multi-walled carbon nanotubes were dried at 100° C. for 30 min to obtain a dry precursor. Put the dried precursor in a muffle furnace, feed it with argon, heat it to 700°C, and keep it warm for 0.5h; cool it down to room temperature with the furnace, take it out of the furnace, grind it finely, and get the vanadium trioxide product. Use ammonium ferrous sulfate-titration method (GB / T 20567-2006) to measure the vanad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com