Acrylate emulsion for waterborne multicolor paint and production process of acrylate emulsion

A water-based colorful paint and acrylate technology, which is applied in the direction of multi-color effect paint, etc., can solve the effects of polymer electrical properties, optical properties and surface properties, film water resistance, stain resistance, poor gloss, poor compatibility, etc. Problems, to achieve the effect of not easy to hydrolyze, low cost of use, good defoaming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

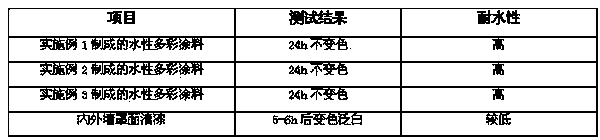

Examples

Embodiment 1

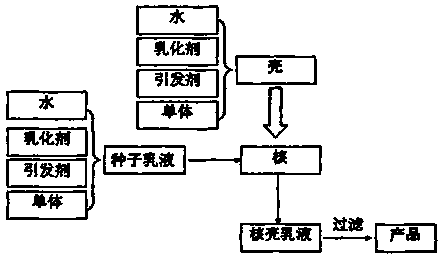

[0024] Example 1: Such as figure 1 As shown, a kind of acrylate emulsion for water-based colorful paint and its production process, the water acrylate emulsion is prepared by mixing water, emulsifier, initiator solution I, initiator solution II and monomers. The production process includes the following:

[0025] 1) Preparation of initiator: 0.2 parts by weight of ammonium persulfate was dissolved in 5 parts by weight of water to obtain initiator solution I; 0.4 parts by weight of ammonium persulfate was dissolved in 30 parts by weight of water to obtain initiator solution II;

[0026] 2) Preparation of emulsion: Add 200 parts by weight of water, 5 parts by weight of allyl polyether ammonium sulfate emulsifier, 250 parts by weight of methyl methacrylate, and 170 parts by weight of acrylic acid into the emulsification reactor Butyl ester, 5 parts by weight of methacrylic acid and 5 parts by weight of hydroxyethyl methacrylate, stirred and reacted for 50 minutes to obtain an ...

Embodiment 2

[0033] Example 2: Such as figure 1 Shown is an acrylate emulsion for water-based colorful paint and its production process. The acrylate emulsion is prepared by mixing water, emulsifier, initiator solution I, initiator solution II and monomers. Its production The process includes the following:

[0034] 1) Preparation of initiator: 0.5 parts by weight of potassium persulfate was dissolved in 10 parts by weight of water to obtain initiator solution I; 1.2 parts by weight of potassium persulfate was dissolved in 50 parts by weight of water to obtain initiator solution II;

[0035] 2) Preparation of emulsion: Add 250 parts by weight of water, 9 parts by weight of allyl polyether ammonium sulfate emulsifier, 300 parts by weight of methyl methacrylate, and 210 parts by weight of acrylic acid into the emulsification reactor Butyl ester, 10 parts by weight of methacrylic acid and 10 parts by weight of hydroxyethyl methacrylate, stirred and reacted for 60 minutes to obtain an emuls...

Embodiment 3

[0042] Example 3: Such as figure 1 Shown is an acrylate emulsion for water-based colorful paint and its production process. The acrylate emulsion is prepared by mixing water, emulsifier, initiator solution I, initiator solution II and monomers. Its production The process includes the following:

[0043] 1) Preparation of initiator: 0.3 parts by weight of potassium persulfate was dissolved in 8 parts by weight of water to obtain initiator solution I; 1.0 parts by weight of potassium persulfate was dissolved in 40 parts by weight of water to obtain initiator solution II;

[0044] 2) Preparation of emulsion: Add 230 parts by weight of water, 7 parts by weight of allyl polyether ammonium sulfate emulsifier, 280 parts by weight of methyl methacrylate, and 200 parts by weight of acrylic acid into the emulsification reactor Butyl ester, 7 parts by weight of methacrylic acid and 8 parts by weight of hydroxyethyl methacrylate, stirred and reacted for 55 minutes to obtain an emulsion...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com