Hard closed melamine foam and preparing method thereof

A technology of closed-cell melamine and foam, which is applied in the field of material science and processing, can solve problems such as flammability and heat resistance, and achieve the effects of simple process, low production cost, and easy popularization and application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

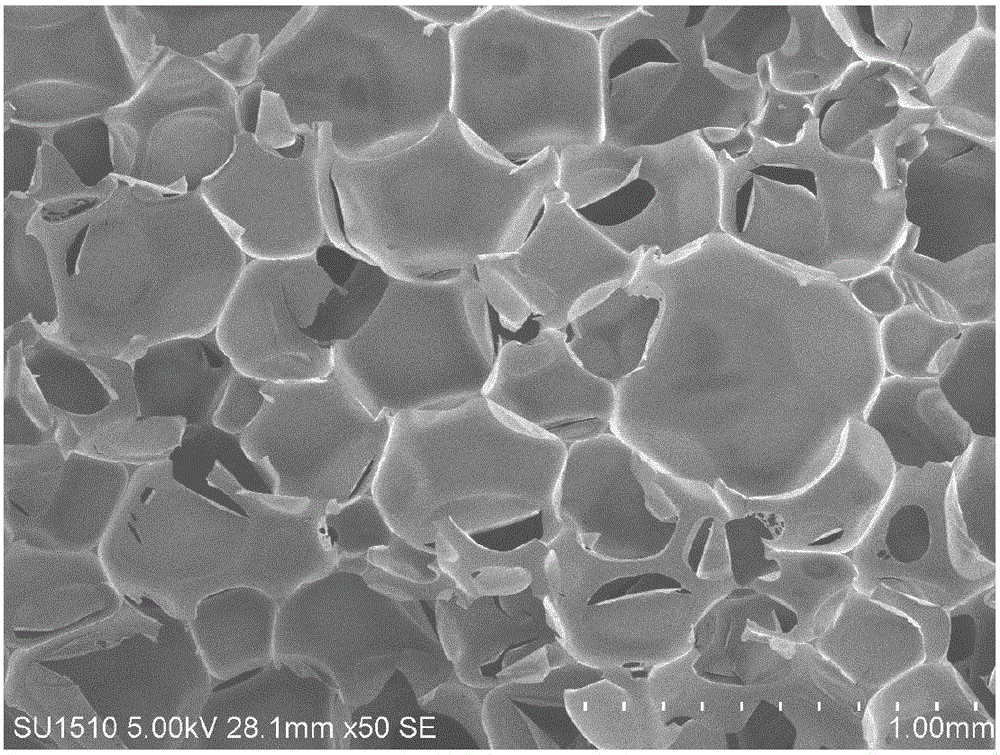

Image

Examples

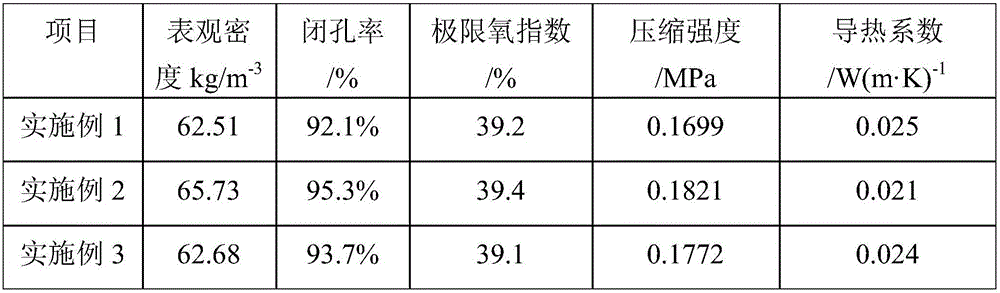

Embodiment 1

[0023] A rigid closed-cell melamine foam, the preparation method of which comprises the following steps:

[0024] (1) add melamine and high-concentration formaldehyde solution (mass concentration is 70%) in the reactor, adopt hexamethylenetetramine to adjust the solution to be weakly alkaline pH is 7.5, raise temperature to 60 ℃ simultaneously, at 200r Under the mechanical stirring effect of / min, the two are slowly reacted for 40min; the molar ratio of melamine and high-concentration formaldehyde solution is 1:3;

[0025] (2) when the solution is clear and transparent, the pH value of the reaction solution is adjusted by using diisoolamine to be 8.5, and the temperature is raised to 80°C and then the reaction is incubated for 70min;

[0026] (3) When the resin viscosity is 1400mPa·s, measure the water tolerance of the resin, when the water tolerance reaches 1.8, stop the reaction by cooling down, cool down to 35°C, add sodium citrate, stir evenly, and place it in an ice-water...

Embodiment 2

[0031] A rigid closed-cell melamine foam, the preparation method of which comprises the following steps:

[0032] (1) add melamine and high-concentration formaldehyde solution (mass concentration is 50%) in the reactor, adopt hexamethylenetetramine to adjust the solution to be weakly alkaline pH is 7, raise temperature to 60 ℃ simultaneously, at 200r Under the mechanical stirring effect of / min, the two are slowly reacted for 40min; the molar ratio of melamine and high-concentration formaldehyde solution is 1:3;

[0033] (2) when the solution is clear and transparent, then use 30wt% NaOH solution to adjust the pH value of the reaction solution to 9, and after raising the temperature to 90°C, carry out the insulation reaction for 80min;

[0034] (3) When the resin viscosity is 1670mPa·s, measure the water tolerance of the resin, when the water tolerance reaches 2.0, stop the reaction by cooling down, cool down to 35℃, add the stabilizer sodium citrate, stir evenly, and place it...

Embodiment 3

[0038] A rigid closed-cell melamine foam, the preparation method of which comprises the following steps:

[0039] (1) adding melamine and high-concentration formaldehyde solution (mass concentration is 60%) in the reactor, using diisoolamine to adjust the solution to be weakly alkaline pH is 8, and raising the temperature to 65 ° C simultaneously, at 200r / min Under the action of mechanical stirring, make the two react slowly for 30min; the molar ratio of melamine and high-concentration formaldehyde solution is 1:3;

[0040] (2) when the solution is clear and transparent, then use diisoolamine to adjust the pH value of the reaction solution to 8.5, and carry out the insulation reaction for 90min after raising the temperature to 65°C;

[0041] (3) When the resin viscosity is 1920mPa·s, the water tolerance of the resin is measured. When the water tolerance reaches 2.3, the reaction is terminated by lowering the temperature. The temperature is lowered to 35°C, and the stabilizer s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com