Device and method for preparing low-density polymeric foam beads by utilizing extrusion and foaming of supercritical mixed fluid

A technology of supercritical fluid and mixed fluid, applied in the direction of coating, etc., can solve the problems of small expansion ratio, low production efficiency, poor adaptability of different polymer materials, etc., and achieve the effect of high porosity and large-scale precise regulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

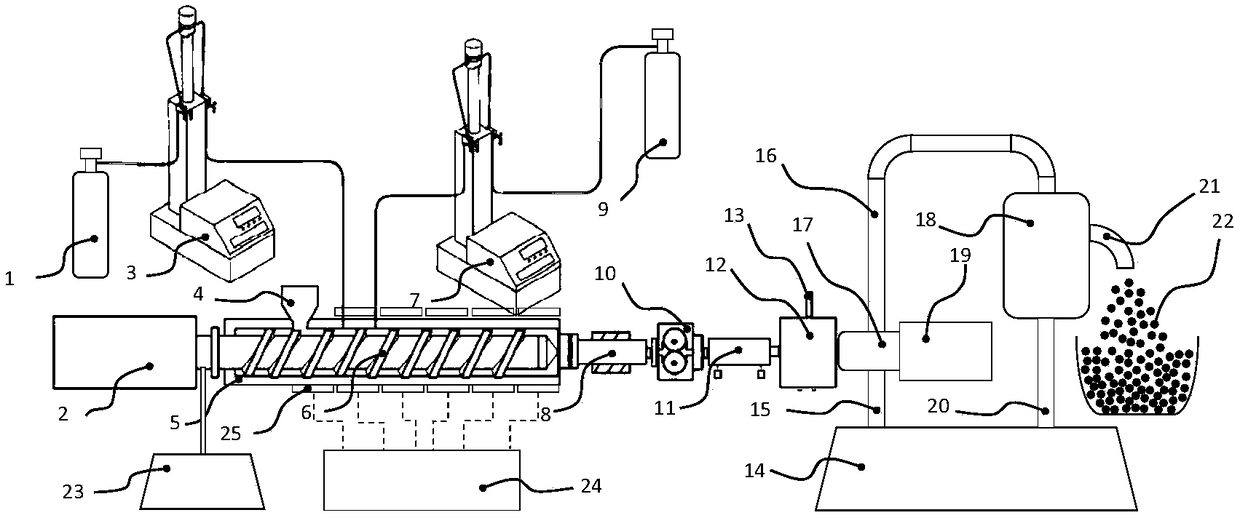

[0060] device as figure 1 The shown "Using Supercritical Mixed Fluid Extrusion and Foaming Device to Prepare Low-density Polymer Foam Beads", the raw material is thermoplastic polyurethane, and its melt index and density are 12g / 10min (@220℃ / 10kg), 1.18g / cm 3 (@23°C); supercritical fluid I is carbon dioxide with a purity of 99.9%, and supercritical fluid II is nitrogen with a purity of 99.5%; the injection amount of carbon dioxide is 2.5% by weight, and the injection amount of nitrogen is 0.25% by weight.

[0061] The diameter of the screw of the twin-screw extruder is 80mm, and its aspect ratio is 40. The temperature of the twin-screw is set at 180°C; ℃–200℃–200℃–200℃–200℃–200℃–190℃–180℃–170℃–170℃, the screw speed is 30 rpm; two supercritical fluids on the barrel of the twin-screw extruder The distance between the injection port and the hopper is 5 times the screw diameter and 10 times the screw diameter; the temperature of the static mixer is set to 150°C; the control pre...

Embodiment 2

[0064] device as figure 1 The shown "Using Supercritical Mixed Fluid Extrusion and Foaming Device to Prepare Low-density Polymer Foam Beads", the raw material is high-melt strength polypropylene, and its melt index and density are 16g / 10min (@230℃ / 2.16 kg), 0.90g / cm 3 (@23°C); supercritical fluid I is carbon dioxide with a purity of 99.9%, and supercritical fluid II is nitrogen with a purity of 99.5%; the injection amount of carbon dioxide is 5.0% by weight, and the injection amount of nitrogen is 0.32% by weight.

[0065] The diameter of the screw of the twin-screw extruder is 60mm, its aspect ratio is 50, and the temperature of the twin-screw is set at 170°C; the temperature of the barrel of the twin-screw extruder is set at 60°C–160°C–180 ℃–180℃–180℃–180℃–180℃–180℃–180℃–170℃–170℃–170℃, the screw speed is 30 rpm; two supercritical fluids on the barrel of the twin-screw extruder The distance between the injection port and the hopper is 10 times the screw diameter and 18 tim...

Embodiment 3

[0068] device as figure 1 The shown "Using Supercritical Mixed Fluid Extrusion and Foaming Device to Prepare Low-density Polymer Foam Beads", the raw material is high-melt strength polypropylene, and its melt index and density are 16g / 10min (@230℃ / 2.16 kg), 0.90g / cm 3 (@23°C); supercritical fluid I is carbon dioxide with a purity of 99.9%, and supercritical fluid II is nitrogen with a purity of 99.5%; the injection amount of carbon dioxide is 4.0% by weight, and the injection amount of nitrogen is 0.2% by weight.

[0069] The diameter of the screw of the twin-screw extruder is 100mm, and its aspect ratio is 60. The temperature of the twin-screw is set at 180°C; ℃–200℃–200℃–200℃–200℃–190℃–190℃–180℃–170℃–170℃, the screw speed is 25 rpm; two supercritical fluids on the barrel of the twin-screw extruder The distance between the injection port and the hopper is 15 times the screw diameter and 25 times the screw diameter; the temperature of the static mixer is set to 155°C; the co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Average cell diameter | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com