Modified hard bubble polyurethane composite plate and manufacturing method thereof

A rigid foam polyurethane and composite board technology, which is applied in the field of building thermal insulation materials, can solve the problems of low closed cell rate, high thermal conductivity and foam water absorption rate, poor thermal insulation and waterproof and impermeability of the rigid foam polyurethane composite board, and achieves thermal insulation. The performance and waterproof and impermeability are improved, the waterproof and impermeability is good, and the effect of preventing fire

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

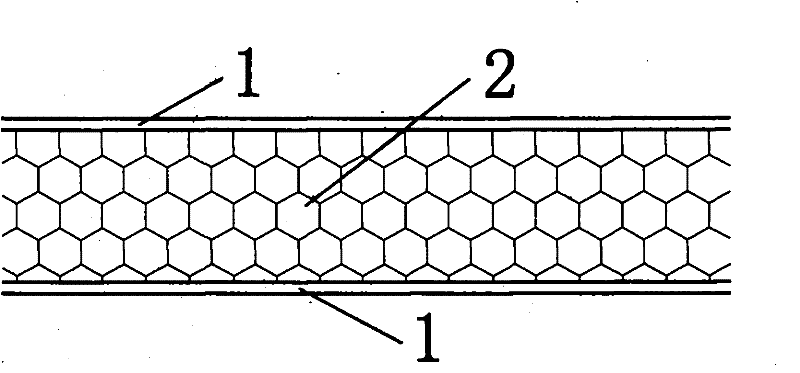

[0036] The modified rigid foam polyurethane composite board made according to the method of this embodiment can refer to figure 1 , it shows the waterproof and fireproof coiled material without tire base or reinforcement net on both sides of the rigid foam polyurethane insulation layer. It can be seen from Figure 1 that it is composited on both sides of the insulation layer 2 without The waterproof and fireproof coiled material 1 with tire base or reinforcement net without reinforcement, and the rigid polyurethane foam insulation layer 2 are nano-silica airgel obtained by adding 3.5% polyurethane foam weight to polyurethane foam and drying under normal pressure.

[0037] The specific production process is as follows:

[0038] Production of polymer glue: Weigh raw materials according to the following weight ratio: 90% pure acrylic emulsion, 0.5% film-forming aid, 0.1% defoamer, 0.4% dispersant, 3% flame retardant, 6% water, add to the mixing tank and mix well.

[0039] Produc...

Embodiment 2

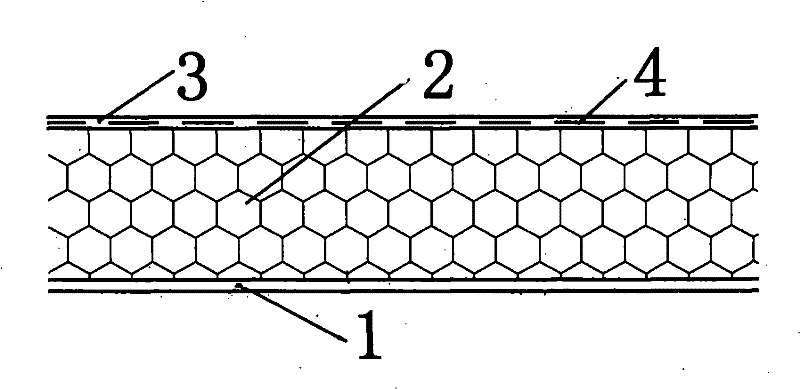

[0043] Another kind of modified rigid foam polyurethane composite board made according to the method of this embodiment can refer to figure 2 , it shows the waterproof and fireproof coiled material without tire base or reinforced net on one side of the insulation layer, and the waterproof and fireproof coiled material with tire base or reinforced net on the other side, as can be seen from Figure 2 , it is a waterproof and fireproof coiled material 1 without a tire base or a reinforced mesh on one side of the insulation layer 2, and a waterproof and fireproof coiled material 3 with a tire base or a reinforced mesh 4 on the other side. The reinforcement net 4 can be made of glass fiber felt, and the insulation layer 2 is nano-silica aerogel obtained by adding 5% polyurethane foam weight to the polyurethane foam and drying under normal pressure.

[0044] The specific production process is as follows:

[0045] Production of polymer glue: Weigh raw materials according to the foll...

Embodiment 3

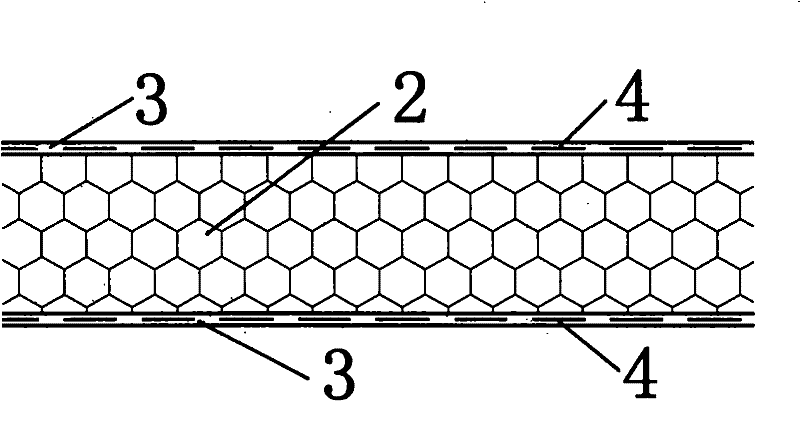

[0052] The third modified rigid foam polyurethane composite board made according to the method of this embodiment can refer to image 3 , which shows a waterproof and fireproof membrane with tire base or reinforced mesh on both sides of the insulation layer. image 3 It can be seen from the figure that it is a waterproof and fireproof coiled material 3 compounded with tire base or reinforcement mesh 4 on both sides of the insulation layer 2, the tire base or reinforcement mesh 4 is glass fiber felt, and the insulation layer 2 is made of polyurethane foam. Added 1.5% polyurethane foam weight nano-silica aerogel obtained through normal pressure drying.

[0053] The specific production process is as follows:

[0054] The production of polymer glue: take the raw materials according to the following weight ratio: 85% VAE emulsion, 1% film-forming aid, 0.5% thickener, 0.3% defoamer, 0.9% dispersant, 4% retarder Combustion agent, 8.3% water, add in stirring tank and mix evenly.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com