Homogenous low-heat-conductivity inorganic heat insulation board and preparation method thereof

An inorganic thermal insulation board and low thermal conductivity technology, applied in the field of new materials, can solve the problems of complex manufacturing process and increased cost, and achieve the effects of simple preparation process, improved toughness, and improved flame retardancy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

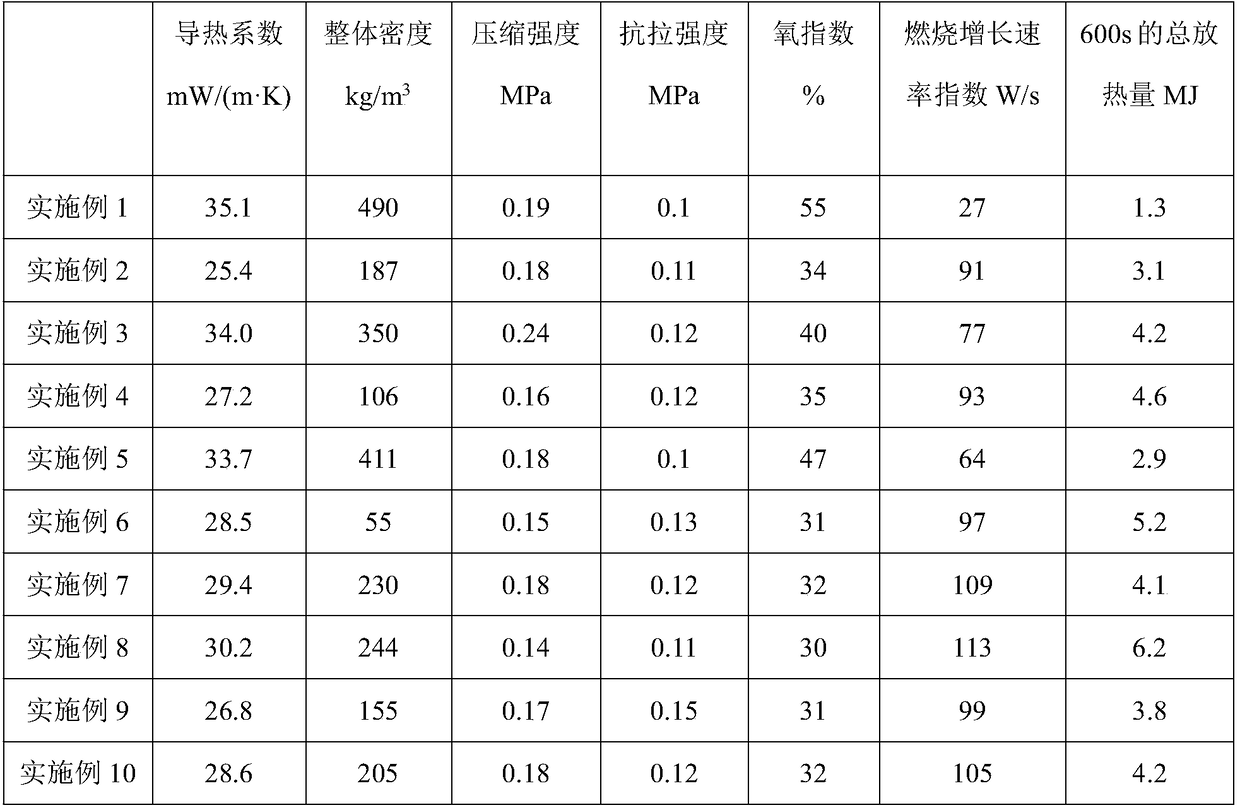

Examples

Embodiment 1

[0039] Preparation of inorganic materials: 65 parts by weight of 60-80 mesh emery, 10 parts by weight of calcium hydroxide of 100 mesh, 5 parts by weight of expandable graphite, and 5 parts by weight of α-alumina trihydrate;

[0040] The preparation of component A of rigid polyurethane foaming material: 100 parts by weight of polyester polyol PS-2502 (Stepan), 4.0 parts by weight of dimethylcyclohexylamine, 0.5 parts by weight of dibutyltin dilaurate, HCFC-141b 23 parts by weight, 2 parts by weight of water, 10 parts by weight of tris (2-chloropropyl) phosphate, 10 parts by weight of dimethyl methyl phosphate, 1.15 parts by weight of foam stabilizer AK8805 (Mei Si De); Preparation: Take 211 parts by weight of polyphenyl polymethylene polyisocyanate M20S (Basf).

[0041] The dried inorganic materials are prepared into a mixture in proportion, and the temperature during mixing is 15°C; the mixture is continuously conveyed, and at the same time, continuously metered polyurethane ...

Embodiment 2

[0043] Preparation of inorganic materials: 16 parts by weight of lime powder of 2000 mesh, 20 parts by weight of waste glass powder of 50-100 mesh, 5 parts by weight of aluminum silicate fiber with a fiber length of 1.0-3.5 mm, and 10 parts by weight of borax;

[0044] Preparation of component A of rigid polyurethane foaming material: 27 parts by weight of polyether polyol HP2502 (Hongbaoli), 73 parts by weight of polyester polyol HF-8730 (Huafeng), and 1.9 parts by weight of triethylenediamine , 0.4 parts by weight of potassium isooctanoate-dipropylene glycol solution, 8 parts by weight of pentane, 7 parts by weight of HFC-245fa, CO 2 5 parts by weight, 1.6 parts by weight of water, 5 parts by weight of tris(2-chloropropyl) phosphate, 1.1 parts by weight of foam stabilizer B8460 (Degussa); the preparation of B component: take polyphenylpolymethylene 221 parts by weight of polyisocyanate PM-400 (Wanhua Chemical).

[0045] The dried inorganic materials are prepared into a mixt...

Embodiment 3

[0047] Preparation of inorganic materials: 5 parts by weight of 60-mesh fly ash, 25 parts by weight of quartz sand of 140-200 mesh, 10 parts by weight of expanded perlite of 200-270 mesh, 10 parts by weight of hollow glass microspheres of 400 mesh, 10 parts by weight of magnesium hydroxide Parts by weight, 2 parts by weight of antimony oxide;

[0048] Preparation of filler: get 5 parts by weight of rice husk, 5 parts by weight of bark;

[0049] Preparation of component A of rigid polyurethane foaming material: take 100 parts by weight of polyether polyol H4110 (Hongbaoli), 2.0 parts by weight of triethanolamine, 1,3,5-tris(dimethylaminopropyl) symmetrical hexahydro 1.5 parts by weight of triazine, 4.2 parts by weight of water (2.0 parts by weight of water are used as blowing agent), 15 parts by weight of diphenylisooctyl phosphate, 3.0 parts by weight of foam stabilizer AK8830 (Meister); the preparation of B component : Take 189 parts by weight of polyphenyl polymethylene pol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com