Enhanced foam stay-in-place building concrete template and manufacturing method thereof

A technology of concrete formwork and manufacturing method, which is applied in building construction, on-site preparation of building components, construction, etc., can solve the problems of reduced thermal insulation performance, time-consuming and labor-intensive, uneven distribution of micropore size, etc., and achieves high compressive strength. and impact resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

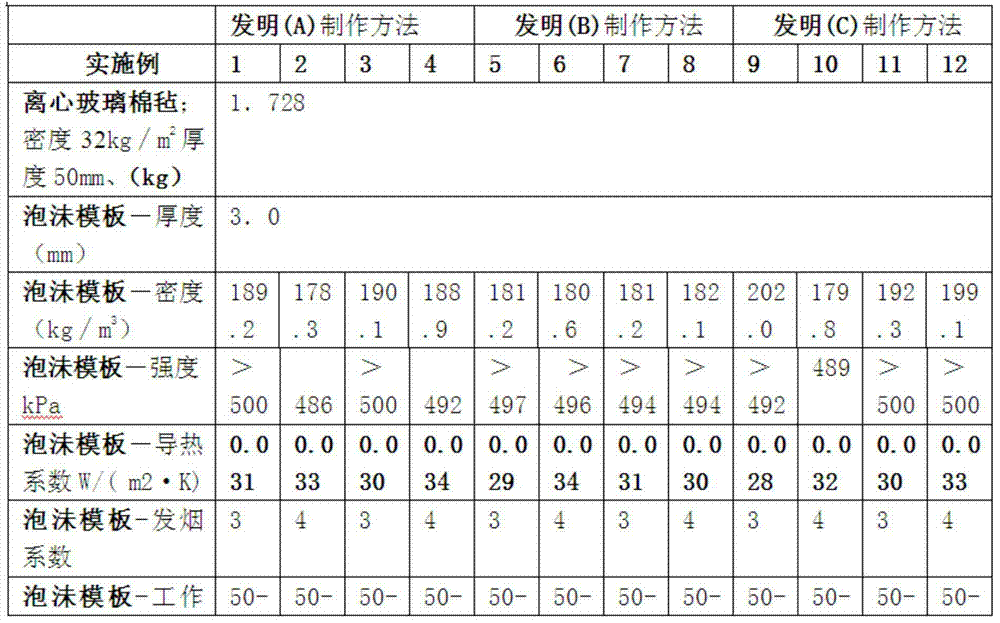

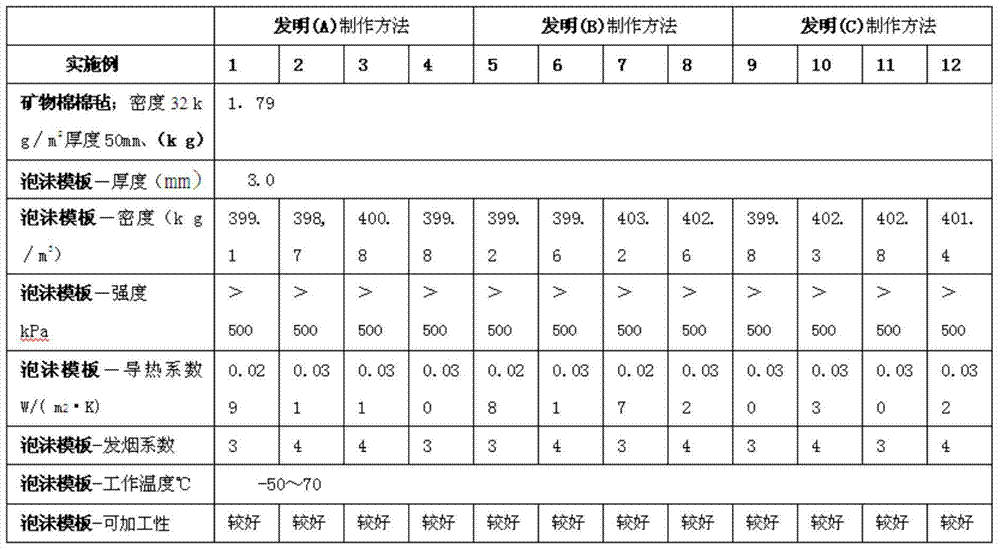

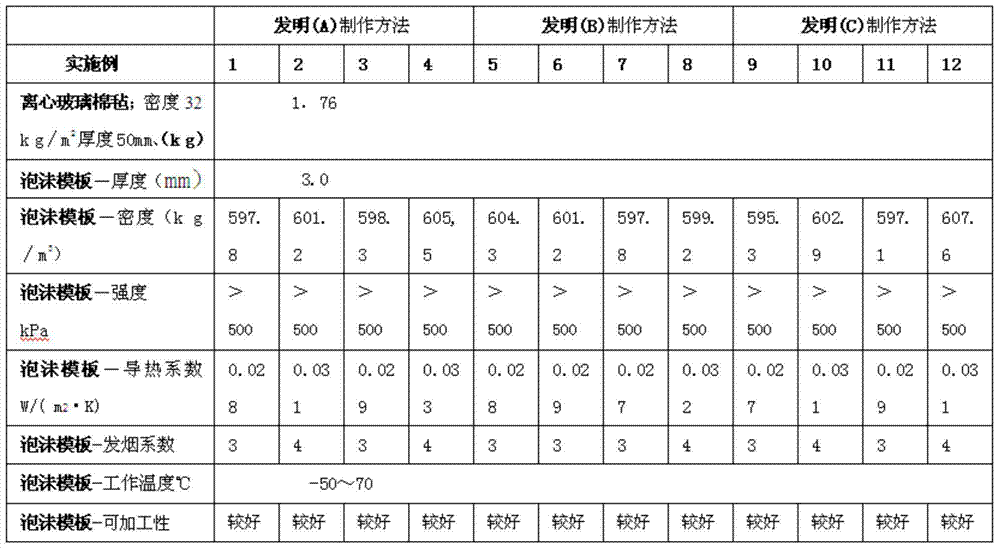

Embodiment 1

[0045]In the mold where the template needs to be prepared, evenly lay the required specifications of glass wool or mineral wool felt, and quantitatively impregnate the phenolic resin with the fibers in the glass wool or mineral wool felt naturally, fully and evenly. Under the action of glass wool or mineral wool fiber surface treatment agent, foaming agent, surfactant, curing agent, modifier, and penetrating agent mixed uniformly in phenolic resin in advance, in the closed and limited space of the mold, a Uniform, dense, high-closed-cell microporous foam material with independent cells, the temperature in the mold cavity is controlled at 40-120°C, and the time is 20-70 minutes. The glass wool or mineral wool fiber surface treatment agent is: vinyl triethoxysilane, which is added to the phenolic resin in a weight ratio of 0.5-1.5%. The penetrating agent is methanol, which is added in a weight ratio of 3-6% to the phenolic resin. The foaming agent is isopentane, and the weight ...

Embodiment 2

[0047] In the mold where the template needs to be prepared, evenly lay the required specifications of glass wool or mineral wool felt, and quantitatively impregnate the phenolic resin with the fibers in the glass wool or mineral wool felt naturally, fully and evenly. Under the action of glass wool or mineral wool fiber surface treatment agent, foaming agent, surfactant, curing agent, modifier, and penetrating agent mixed uniformly in phenolic resin in advance, in the closed and limited space of the mold, a Uniform, dense, high-closed-cell microporous foam material with independent cells, the temperature in the mold cavity is controlled at 40-120°C, and the time is 20-70 minutes. The glass wool or mineral wool fiber surface treatment agent is: γ-glycidyl ether propyl trimethoxysilane, which is added to the phenolic resin in a weight ratio of 0.5-1.5%. The penetrating agent is ethylene glycol, which is added in a weight ratio of 3-6% to the phenolic resin. The foaming agent is ...

Embodiment 3

[0049] In the mold where the template needs to be prepared, evenly lay the required specifications of glass wool or mineral wool felt, and quantitatively impregnate the phenolic resin with the fibers in the glass wool or mineral wool felt naturally, fully and evenly. Under the action of glass wool or mineral wool fiber surface treatment agent, foaming agent, surfactant, curing agent, modifier, and penetrating agent mixed uniformly in phenolic resin in advance, in the closed and limited space of the mold, a Uniform, dense, high-closed-cell microporous foam material with independent cells, the temperature in the mold cavity is controlled at 40-120°C, and the time is 20-70 minutes. The glass wool or mineral wool fiber surface treatment agent is vinyl triethoxysilane, which is added to the phenolic resin in a weight ratio of 0.5-1.5%. The penetrating agent is methanol, which is added in a weight ratio of 3-6% to the phenolic resin. The foaming agent is isopentane, and the weight ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com