Cotton fibre rapid staining process

A fast dyeing and process technology, applied in the direction of dyeing, fiber treatment, plant fiber, etc., can solve the problems of high water consumption and high energy consumption, and achieve the effect of shortening the production cycle, simple operation, and avoiding the damage of fiber strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

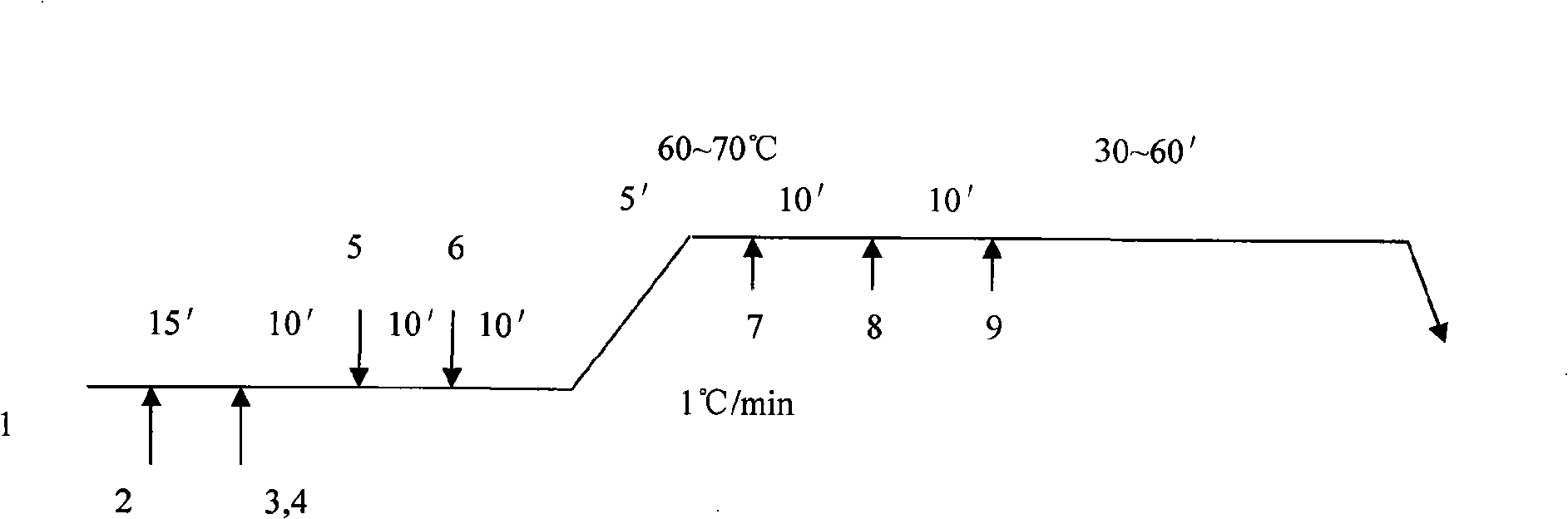

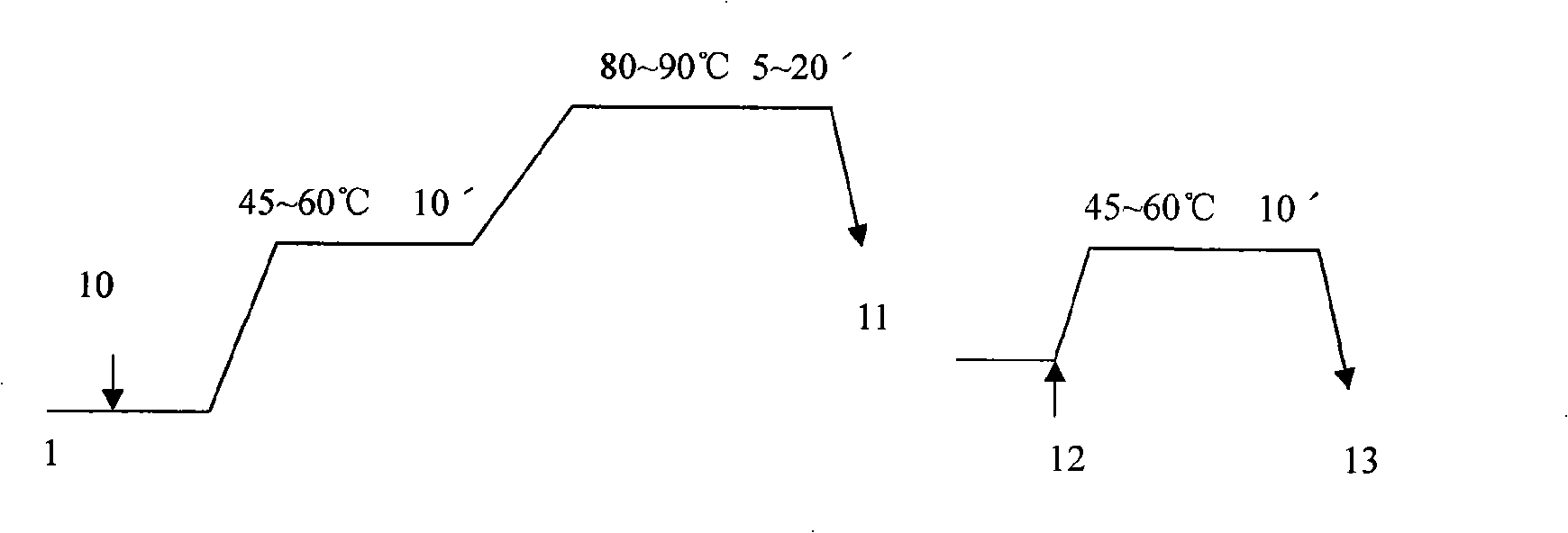

[0041] Select 140 kilograms of cotton loose fibers for use, put it into a water bath with a bath ratio of 1:8 at normal temperature, add 7 kg (5% dosage) of one-bath auxiliary agent FS256 (Fulian Guangdong), and start adding dye after 30 minutes at normal temperature. Use reactive dyes, KN-G2RC black 5.6% 3BS red 2.2% 3RS yellow 0.56% Pour the dye and 1 / 5 yuan Mingfen into the dyeing tank chemical material for 15-20 minutes, run at room temperature for 10 minutes, add 2 / 5 every 10 minutes 5 yuan Mingfen, heat up to 60 degrees at 1 degree per minute and keep warm for 5 minutes, then add 1 / 3 soda ash, add 2 / 3 soda ash after 10 minutes, and drain the liquid after holding the temperature for 30-60 minutes, and then proceed after the liquid is drained Add 2% acidic soaping agent TF230B (Transfer) to water, keep it warm at 40°C for 10 minutes, then raise the temperature to 95°C, soap for 10 minutes, do it twice, and finally fix the color and soften it at 50°C for 30 minutes, add 4 g...

Embodiment 2

[0043] Select 170 kilograms of cotton sliver loose fiber, put it in a water bath with a bath ratio of 1:7 at room temperature, add 3.4g (2% dosage) of one-bath auxiliary agent K-DC for scouring and dyeing (Lanxess, Germany), and run it for 20 minutes at room temperature Start to add dyes, use reactive dyes, the dye formula is KN-R Reactive Brilliant Blue 1.5% BGN Turquoise Blue 0.3%, put the dye and 0.5% soda ash together into the dye vat auxiliary vat 70 degrees chemical material for 15-20 minutes, into the dye vat , keep the temperature running for 10 minutes, add 1 / 5 Yuan Mingfen from the auxiliary tank, require clear water to convert Yuan Mingfen, run for 10 minutes, add 2 / 5 Yuan Mingfen every 10 minutes, and then raise the temperature to 60 at 1 degree per minute Add 1 / 7 soda ash after 5 minutes of heat preservation at high temperature, add 2 / 7 soda ash after 10 minutes, add the remaining 4 / 7 soda ash after another 10 minutes, and drain the liquid after holding the tempera...

Embodiment 3

[0045] Select 200 kg of Xinjiang long-staple combed cotton fiber, put it in a water bath with a liquor ratio of 1:6 at room temperature, add 2 kg (1% dosage) of one-bath auxiliary agent SA (Ciba) for scouring and dyeing, and run it at room temperature for 5 minutes. Start to add dyes, adopt reactive dyes, the dye formula is 3BS red 0.2%, 3RS yellow 0.5%, Yuanqing B 0.3% and pour them into the dye vat auxiliary vat 50 degrees for 10 minutes, put them into the dye vat, keep warm for 5 minutes, from Add 1 / 5 Yuan Mingfen to the auxiliary tank, require clear water to turn Yuan Mingfen, run for 10 minutes, add 2 / 5 Yuan Mingfen every 10 minutes, then raise the temperature at 1°C per minute to 60°C for 5 minutes, then add 1 / 5 7. Soda ash, add 2 / 7 soda ash after 10 minutes, add the remaining 4 / 7 soda ash after another 10 minutes, drain the liquid after holding the temperature for 30~60 minutes, and add acidic soaping agent TF230B 1 to the water after draining %, keep warm at 40°C for 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com