Micro-nano mixed welding paste capable of being used for pressureless sintering and preparation method thereof

A hybrid welding, micro-nano technology, applied in the direction of welding equipment, welding media, manufacturing tools, etc., can solve the problems of obvious volume shrinkage, low stacking density, high production cost, etc., to achieve increased stacking density, smooth particle surface, and equipment simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

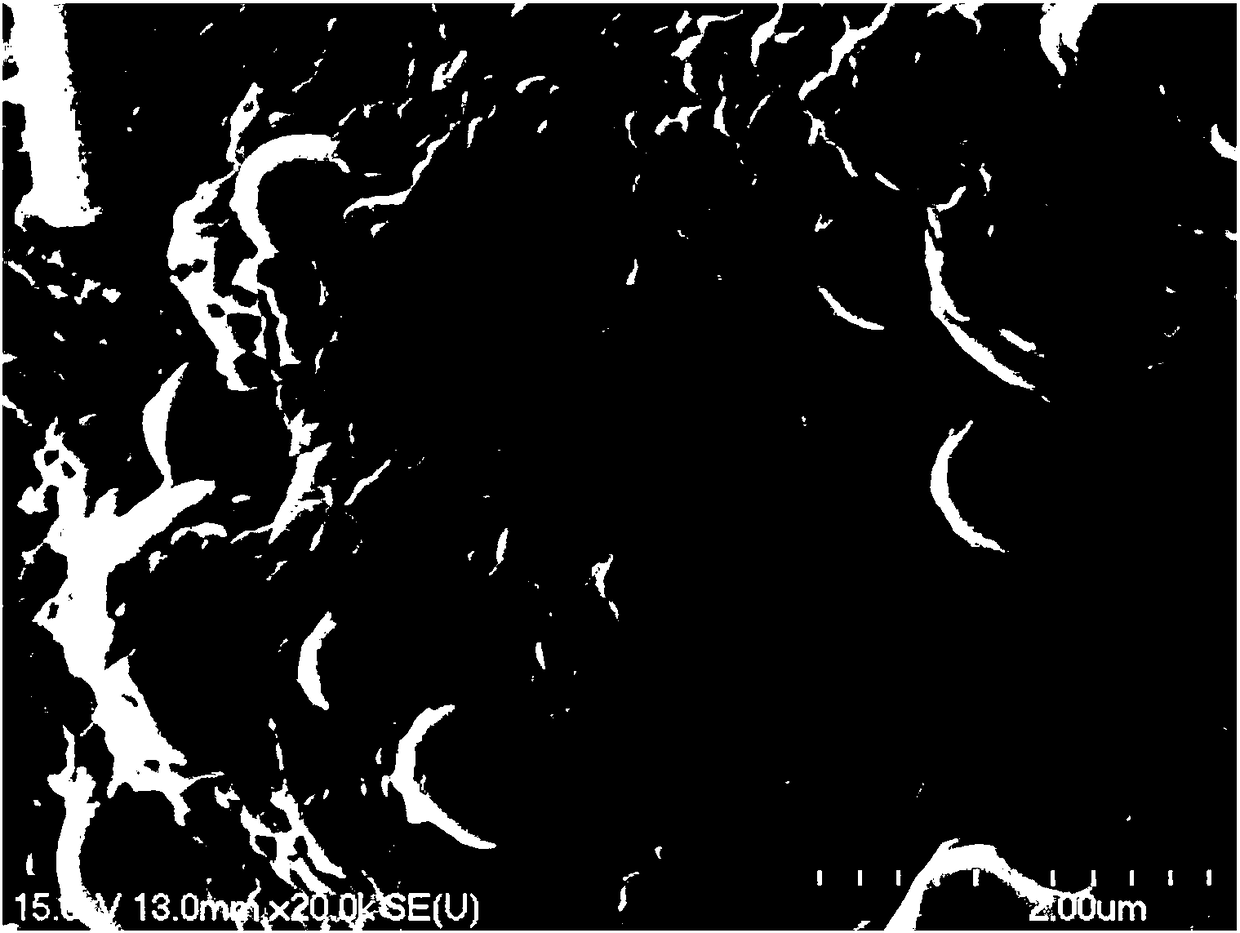

Image

Examples

Embodiment 1

[0037] Embodiment 1 A method for preparing a micro-nano hybrid solder paste that can be used for pressureless sintering, comprising:

[0038] (S1) Clean the micron copper particles with an average particle size of 500nm using a formic acid alcohol solution with a volume fraction of 5%, and then perform centrifugation and drying to obtain micron copper particles with a clean surface;

[0039] (S2) Mechanically mixing micron silver particles with succinic acid, terpineol, ethanol and ethylene glycol to obtain mixture A, wherein the mass percentage of micron copper is 80%, the mass percentage of succinic acid is 0.5%, terpineol The mass percentage of ethanol is 4.5%, the mass percentage of ethanol is 5%, and the rest is ethylene glycol;

[0040] (S3) the average particle diameter is 70nm and is coated with the nano-silver particles of sodium citrate and gelatin, terpineol, ethanol and ethylene glycol mechanically mix, obtain mixture B, wherein nano-silver mass percentage is 80%, ...

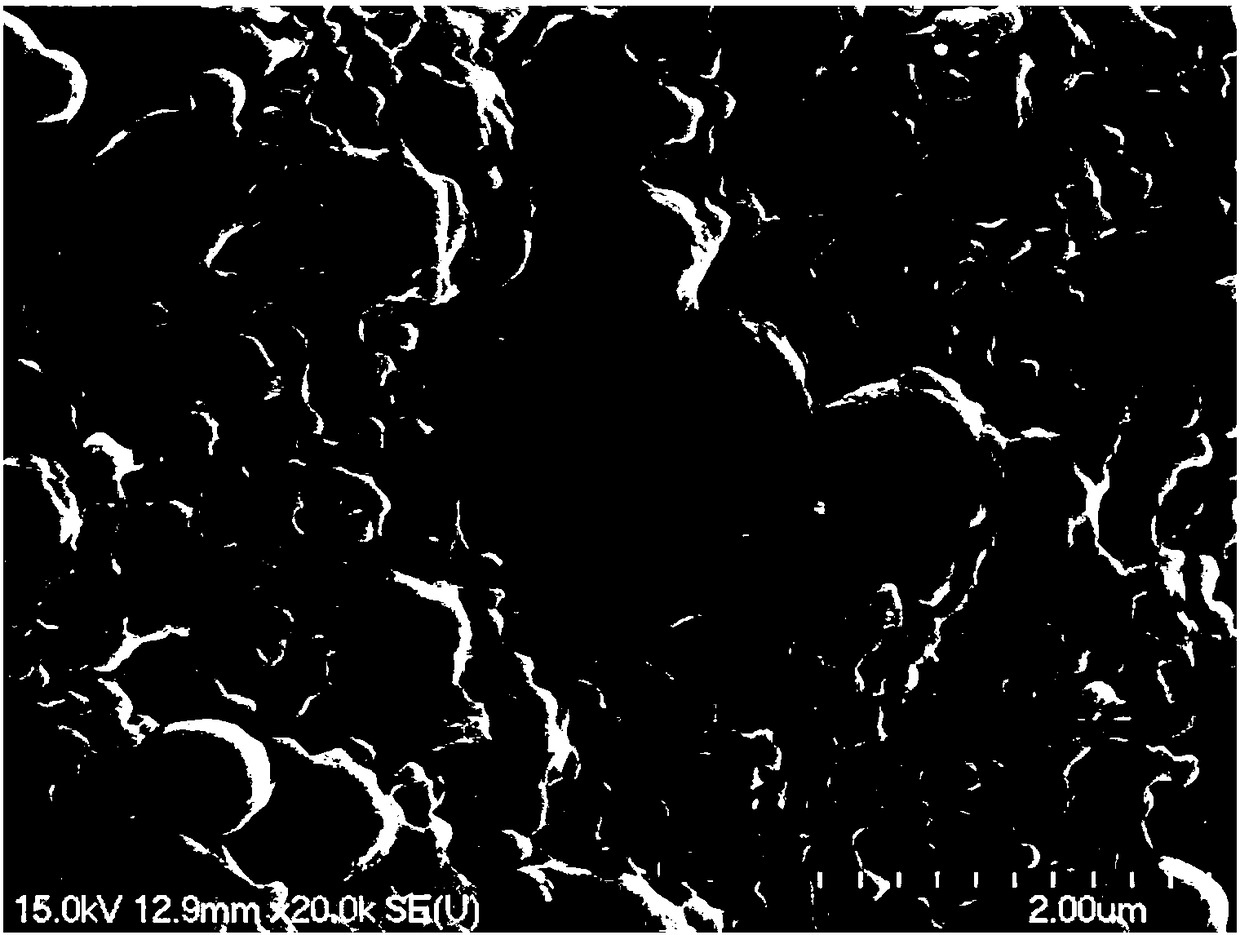

Embodiment 2

[0042] Embodiment 2 A method for preparing a micro-nano hybrid solder paste that can be used for pressureless sintering, comprising:

[0043] (S1) Use a dilute nitric acid alcohol solution with a volume fraction of 5% to clean the micron silver particles with an average particle diameter of 1 μm, and then perform centrifugation and drying to obtain micron silver particles with a clean surface;

[0044] (S2) Mechanically mixing micron silver particles with glutaric acid, ethyl cellulose, butanol and ethylene glycol to obtain mixture A, wherein the mass percentage of micron silver is 84%, the mass percentage of glutaric acid is 0.5%, pine oil The mass percentage of alcohol is 3.5%, the mass percentage of butanol is 7%, and the rest is ethylene glycol;

[0045] (S3) the average particle diameter is 50nm and the nano-silver particles coated with sodium citrate are mechanically mixed with fish oil, ethyl cellulose, butanol and ethylene glycol to obtain mixture B, wherein the mass p...

Embodiment 3

[0047] Embodiment 3 A method for preparing a micro-nano hybrid solder paste that can be used for pressureless sintering, comprising:

[0048] (S1) The micron silver particles with an average particle size of 3 μm are cleaned with a dilute hydrochloric acid alcohol solution with a volume fraction of 5%, and then centrifuged and dried to obtain micron silver particles with a clean surface;

[0049] (S2) Mechanically mixing micron silver particles with abietic acid, butyl carbitol acetate, butanol and propylene glycol to obtain mixture A, wherein the mass percentage of micron silver is 70%, the mass percentage of abietic acid is 0.2%, and butyl carbitol The mass percent of must alcohol acetate is 3.4%, and the mass percent of butanol is 9%, and all the other are ethylene glycol;

[0050] (S3) the average particle diameter is 20nm and the nano-silver particle coated with sodium citrate is mixed with sodium dodecyl sulfonate, butyl carbitol acetate, butanol and ethylene glycol mech...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com