Novel cationic rosin sizing agent and application thereof

A cationic rosin and sizing agent technology, which is applied in the field of papermaking, can solve the problems of poor mechanical stability of rosin sizing agent, instability of emulsifier and dispersed rosin, and improve rosin sizing efficiency, so as to achieve remarkable sizing effect, Emulsion particle performance is stable, improving the effect of paper machine operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

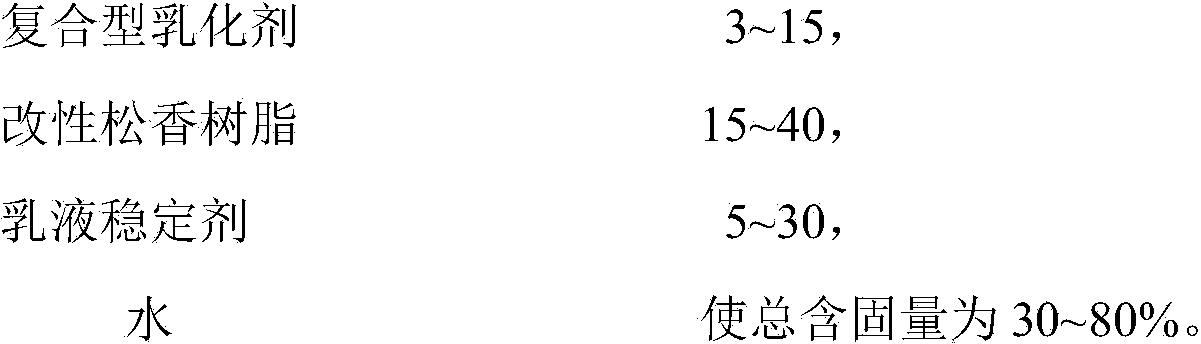

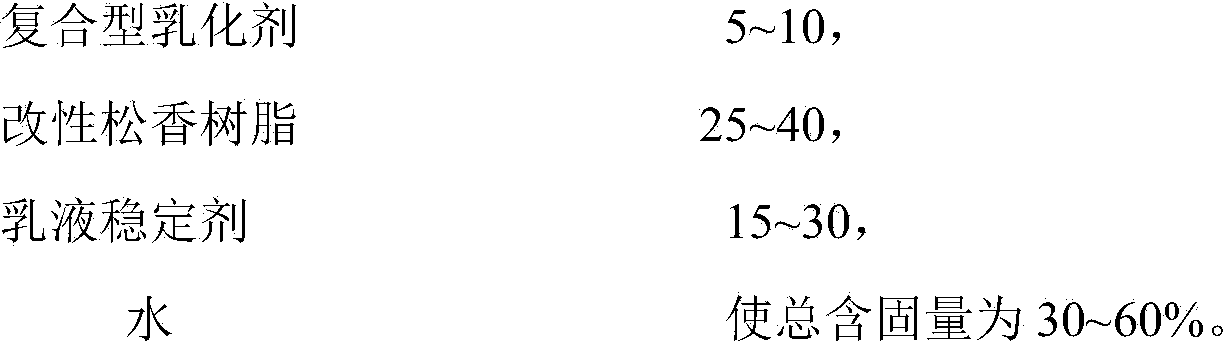

Method used

Image

Examples

preparation example Construction

[0049] 1. Preparation of compound emulsifier

[0050] (1) Preparation of cationic acrylate polymer emulsifier

Synthetic example 1-1

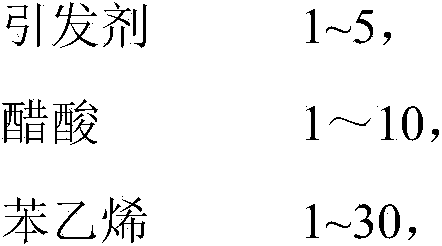

[0052] Add 20 parts of industrial acetic acid with a mass concentration of 99.8% in a reaction device equipped with a stirrer, a thermometer and a reflux condenser, mix 30 parts of styrene, 15 parts of methyl methacrylate, 10 parts of butyl acrylate, and dimethyl methacrylate Mix 15 parts of ethyl amino ethyl ester and 2 parts of dodecanethiol to make mixed monomers, then mix 1 part of azobisisobutyronitrile and mixed monomers uniformly, add them to the reaction device, and react at 85°C for 4 hours , adding deionized water to make the solid content 20%, to obtain a water-soluble copolymer, which is the cationic acrylate polymer emulsifier A1.

Synthetic example 1-2~1-5

[0054] The preparation method is the same as that in Synthesis Example 1-1, and the component ratios are shown in Table 1 to prepare cationic acrylate polymer emulsifiers A2-A5.

[0055] Table 1. Cationic acrylate polymer emulsifiers A2-A5 components (parts by weight)

[0056]

[0057] (2) Preparation of modified polyamide epichlorohydrin resin

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com