Preparation method of waterborne non-isocyanate polyurethane modified polyester

A water-based non-isocyanate, polyurethane modification technology, applied in the direction of coating, etc., can solve the problem that water-based non-isocyanate polyurethane modified polyester has not yet been developed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0040] Preparation method of water-based non-isocyanate polyurethane modified polyester

[0041] In a first aspect of the present invention, a kind of preparation method of the polyester of waterborne non-isocyanate polyurethane modification is provided, and the method may further comprise the steps:

[0042] (1) preparation of unsaturated prepolymer containing urethane bond;

[0043] (2) Preparation of polyester containing unsaturated double bonds;

[0044] (3) the graft polymerization of the polyester containing unsaturated double bond and prepolymer of gained;

[0045] (4) Dispersion of the grafted polymer.

[0046] (1) Preparation of unsaturated prepolymers containing urethane bonds

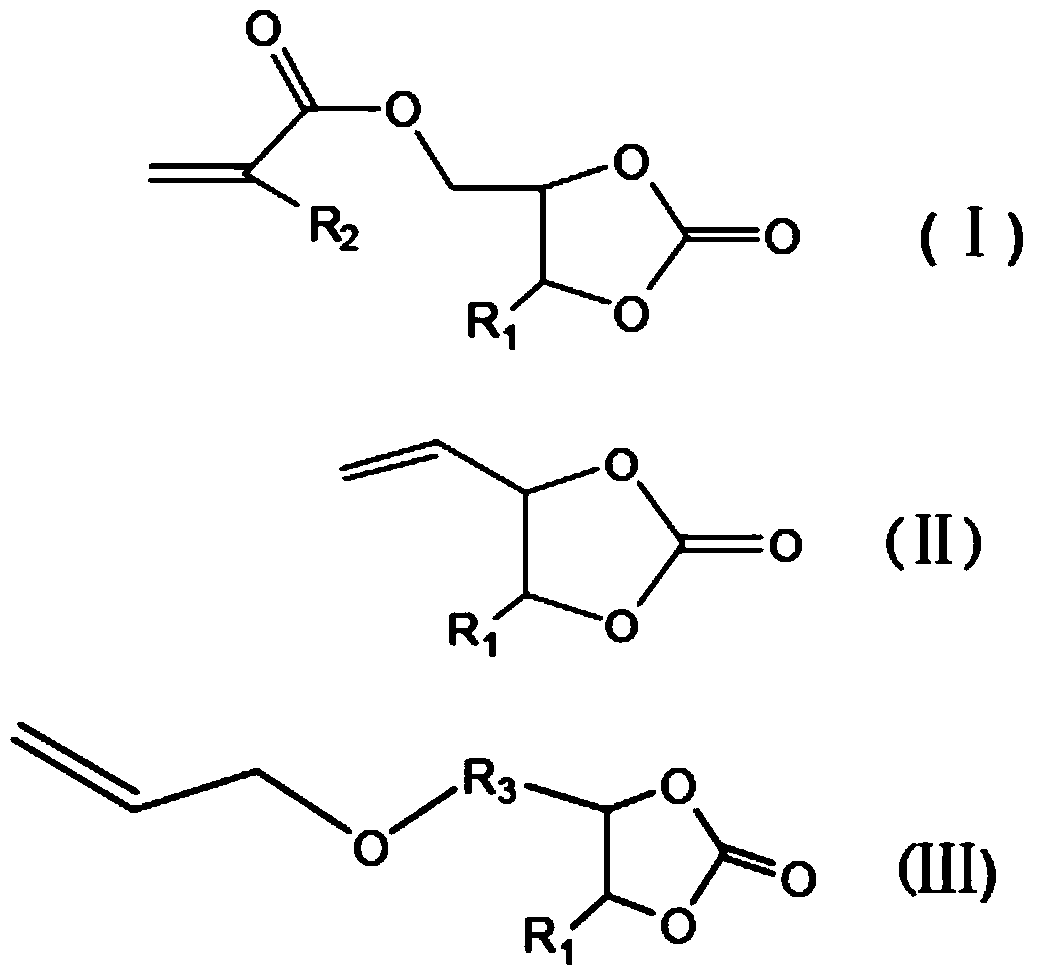

[0047]In this step, an unsaturated prepolymer containing a urethane bond is obtained by reacting a cyclic carbonate containing an unsaturated double bond with a primary amine, wherein the cyclic carbonate containing an unsaturated double bond can be (methyl) Acrylic acid cyclocarbonat...

Embodiment 1

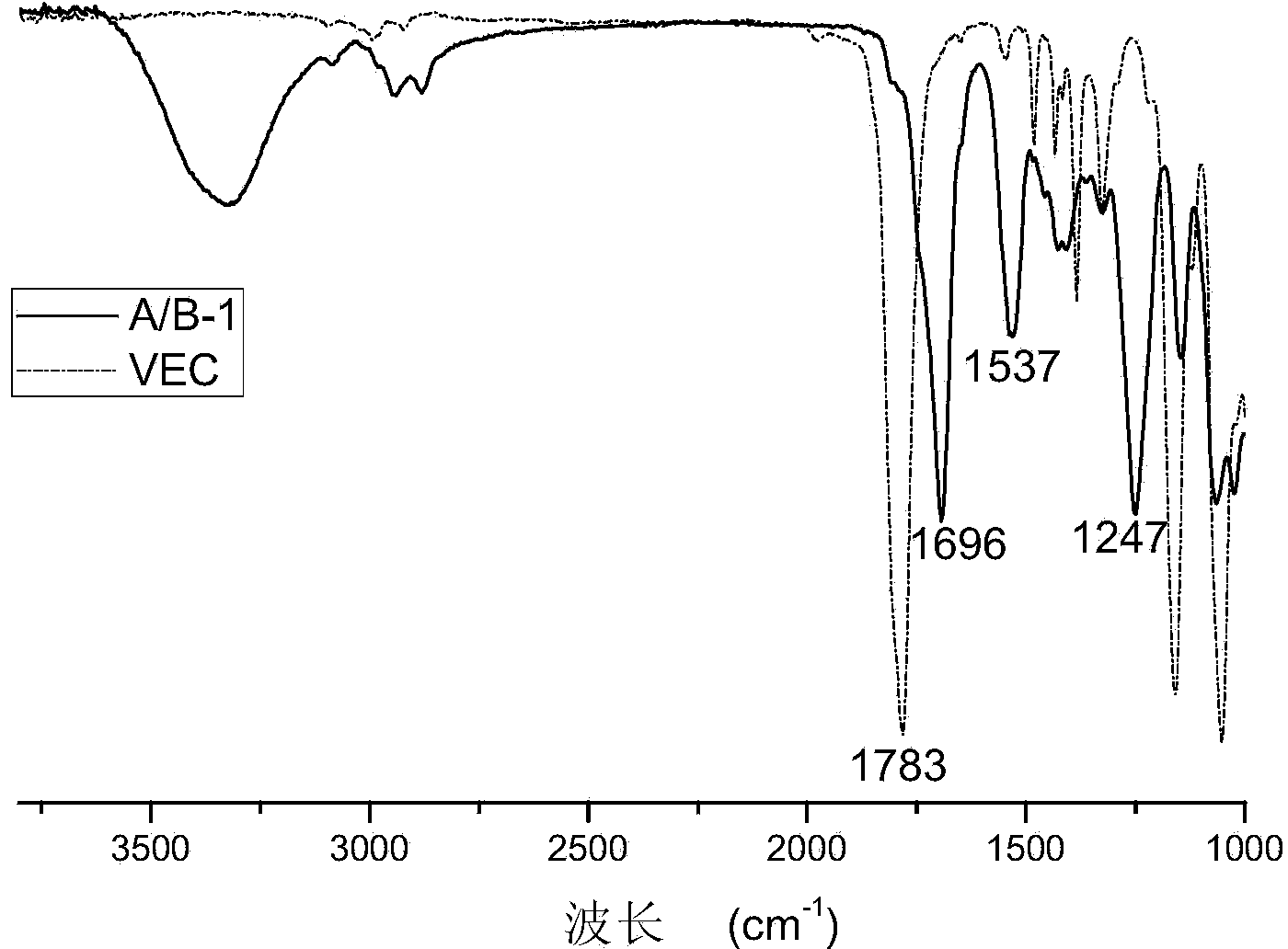

[0089] Step 1): Preparation of Prepolymer A / B-1

[0090] In a four-necked flask equipped with a thermometer, a stirrer, a condenser tube, and a nitrogen conduit, add 119.9 grams of vinyl cyclocarbonate (VEC), 61 grams of monoethanolamine, 0.5 gram of methylimidazole, methylhydroquinone (inhibitor) agent) 0.25 g, in N 2 Under gas protection, react at 120°C for 2-3h, raise the temperature to 150°C for 2-3h, then rise to 160°C for amine value ≤ 5mg KOH / g, cool down and discharge.

[0091] Step 2): Preparation of unsaturated polyester UPE-1

[0092] In a four-neck flask equipped with a thermometer, a stirrer, a water-splitting condenser, and a nitrogen conduit, all the raw materials in Table 1 below except xylene were put in order.

[0093] Table 1

[0094]

[0095] The reaction was carried out at 160-170°C for 2 hours, and the water generated by the reaction was blown with nitrogen, and then the temperature was raised by 10°C every 1 hour until 220°C, and 11.9 g of xylene w...

Embodiment 2

[0105] Step 1): Preparation of Prepolymer A / B-2

[0106] Reaction unit is the same as embodiment 1, adds methacrylic acid cyclocarbonate 195.3 grams, n-butylamine 73.1 grams, the methylimidazole of 0.38 grams, methylhydroquinone (polymerization inhibitor) 0.2 grams, in N 2 Under gas protection, react at 80°C for 2-3h, raise the temperature to 120°C for 2-3h, then raise the temperature to 150°C to react until the amine value is ≤5mg KOH / g, cool down and discharge.

[0107] Step 2): Preparation of unsaturated polyester UPE-2

[0108] The device and process are the same as in Example 1, and all the raw materials except xylene in the following Table 2 are put in successively, and the terminal acid value AV<3mg KOH / g.

[0109]

[0110] The number average molecular weight of the obtained resin is about 4300, the glass transition temperature is about -25°C, the theoretical hydroxyl value is 112 mg KOH / g, and the maleic anhydride content is 3.7%.

[0111] Step 3): Preparation of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Acid value | aaaaa | aaaaa |

| Glass transition temperature | aaaaa | aaaaa |

| Theoretical hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com