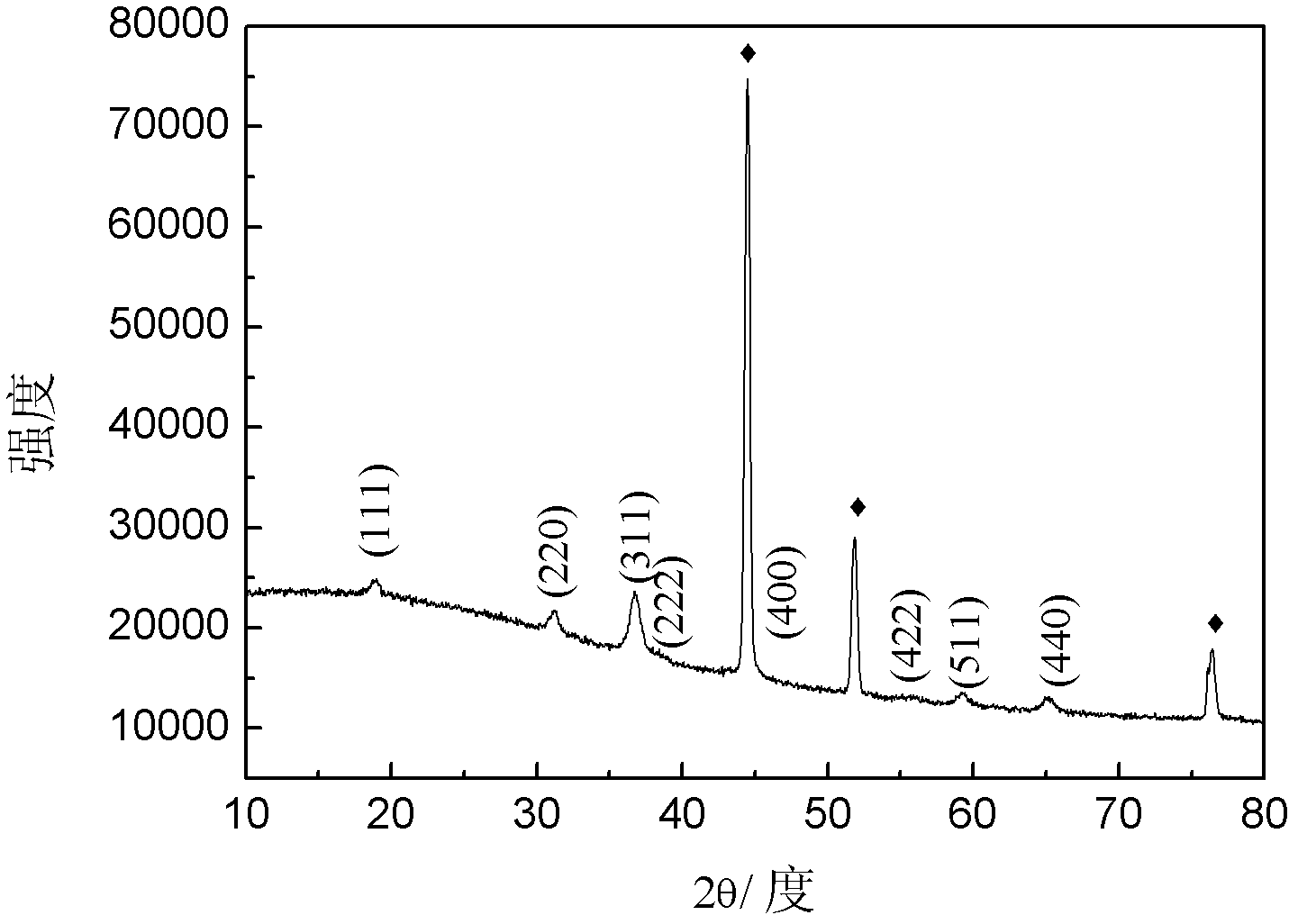

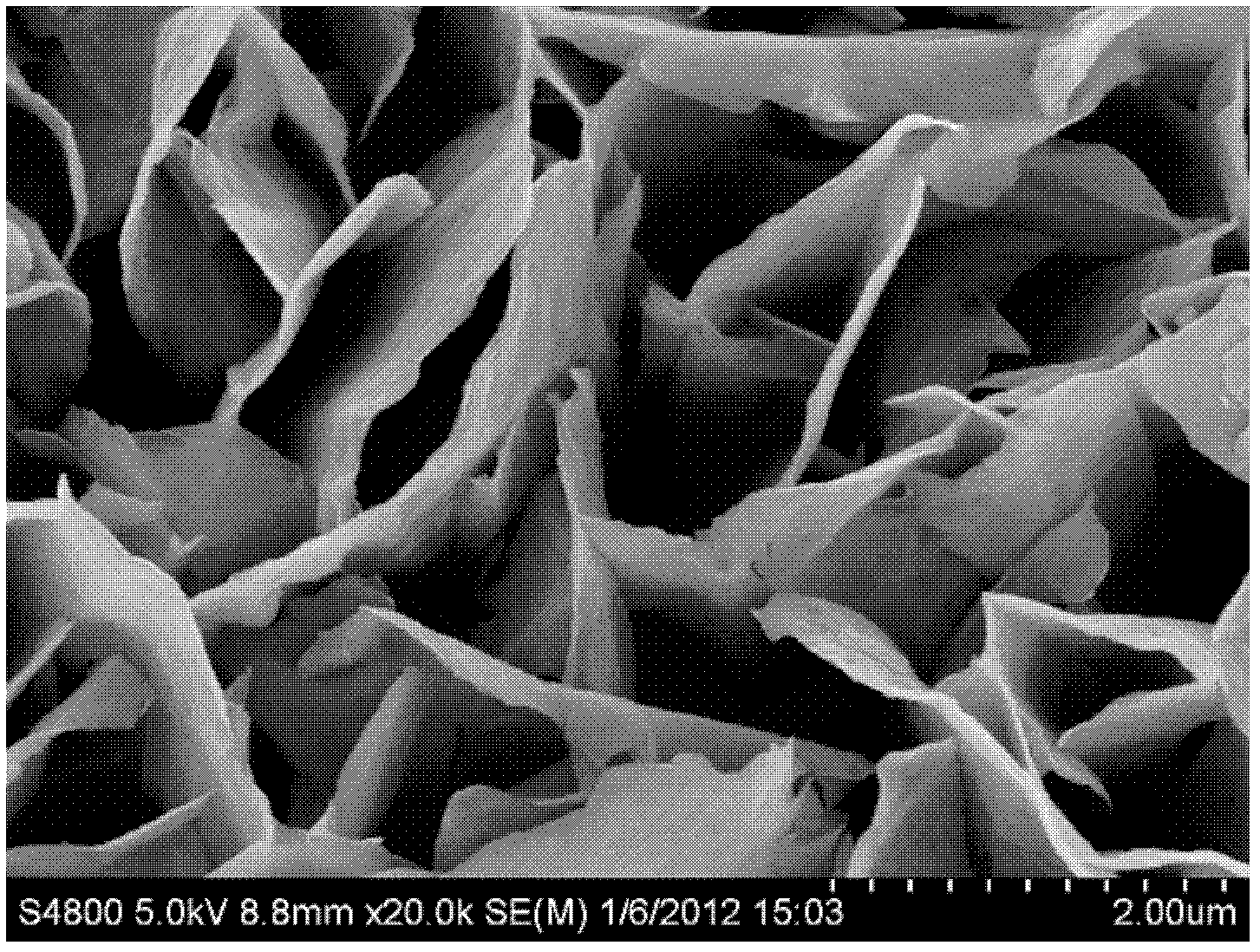

Cobalt oxide anode material, amorphous carbon coated cobalt oxide anode material and preparation method and application of cobalt oxide anode material and amorphous carbon coated cobalt oxide anode material

A technology of tricobalt tetroxide and negative electrode materials, which is applied in the direction of cobalt oxide/cobalt hydroxide, battery electrodes, electrical components, etc., which can solve the problems of unsatisfactory high-power battery rate performance, unsatisfactory capacity and cycle performance, and capacity decline. Excellent performance, low production cost, and the effect of increasing electronic conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] 1) 2.91g of cobalt nitrate hexahydrate and 4.2057g of hexamethylenetetramine were dissolved in 70g of deionized water to obtain an aqueous solution containing cobalt nitrate hexahydrate and hexamethylenetetramine, wherein, containing cobalt nitrate hexahydrate The concentration of cobalt nitrate hexahydrate in the aqueous solution with hexamethylenetetramine is 0.143mol / L, and the concentration of hexamethylenetetramine is 0.429mol / L;

[0037] 2) Pretreat the foamed nickel sheet: select a foamed nickel sheet (commercially available) with a length of 4.5cm, a width of 2.0cm, and a thickness of 2mm, apply a pressure of 10MPa and keep the foamed nickel sheet for 30s to flatten the foamed nickel sheet, and then use ethanol and Clean with acetone, and protect one side of the nickel foam sheet with insulating glue after cleaning.

[0038] In the hydrothermal reaction kettle, place the pretreated foamed nickel sheet in the aqueous solution containing cobalt nitrate hexahydrate...

Embodiment 2

[0046] 1) 2.91g of cobalt nitrate hexahydrate and 4.2057g of hexamethylenetetramine were dissolved in 70g of deionized water to obtain an aqueous solution containing cobalt nitrate hexahydrate and hexamethylenetetramine, wherein, containing cobalt nitrate hexahydrate The concentration of cobalt nitrate hexahydrate in the aqueous solution with hexamethylenetetramine is 0.143mol / L, and the concentration of hexamethylenetetramine is 0.429mol / L;

[0047] 2) Pretreat the foamed nickel sheet: select a foamed nickel sheet (commercially available) with a length of 4.5cm, a width of 2.0cm, and a thickness of 2mm, apply a pressure of 10MPa and keep the foamed nickel sheet for 30s to flatten the foamed nickel sheet, and then use ethanol and Clean with acetone, and protect one side of the nickel foam sheet with insulating glue after cleaning.

[0048] In the hydrothermal reaction kettle, place the pretreated foamed nickel sheet in the aqueous solution containing cobalt nitrate hexahydrate...

Embodiment 3

[0055] 1) 2.91g of cobalt nitrate hexahydrate and 4.2057g of hexamethylenetetramine were dissolved in 70g of deionized water to obtain an aqueous solution containing cobalt nitrate hexahydrate and hexamethylenetetramine, wherein, containing cobalt nitrate hexahydrate The concentration of cobalt nitrate hexahydrate in the aqueous solution with hexamethylenetetramine is 0.143mol / L, and the concentration of hexamethylenetetramine is 0.429mol / L;

[0056] 2) Pretreat the foamed nickel sheet: select a foamed nickel sheet (commercially available) with a length of 4.5cm, a width of 2.0cm, and a thickness of 2mm, apply a pressure of 10MPa and keep the foamed nickel sheet for 30s to flatten the foamed nickel sheet, and then use ethanol and Clean with acetone, and protect one side of the nickel foam sheet with insulating glue after cleaning.

[0057] In the hydrothermal reaction kettle, place the pretreated foamed nickel sheet in the aqueous solution containing cobalt nitrate hexahydrate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com