Organic and inorganic biological compound fertilizer

A kind of compound fertilizer and inorganic technology, applied in the direction of organic fertilizer, organic fertilizer preparation, fertilizer mixture, etc., can solve the problems of backward technology, single component, low nutrient utilization rate of products, etc., to avoid volatilization loss, low utilization rate, Accelerates dehydration and decomposes the effect of organic matter cells and tissues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

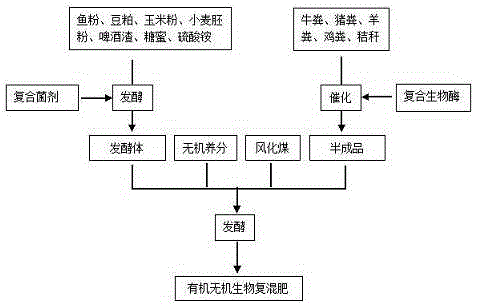

Image

Examples

Embodiment 1

[0029] An organic-inorganic biological compound fertilizer, which is prepared by the following method:

[0030] Step 1: Take 15 parts of Bacillus megaterium inoculum, 20 parts of jelly-like Bacillus inoculum, 15 parts of Saccharomyces cerevisiae inoculum, 15 parts of Lactobacillus acidophilus inoculum, and 15 parts of Trichoderma viride in parts by weight, The components are mixed to obtain a composite microbial agent;

[0031] Step 2: Take 15 parts of fish meal, 15 parts of soybean meal, 15 parts of corn flour, 25 parts of wheat germ powder, 5 parts of beer dregs, 1 part of molasses, 4 parts of ammonium sulfate and the compound microbial agent 2 prepared in step 1 respectively by weight Parts; add fish meal, soybean meal, corn flour, wheat germ powder, beer dregs, molasses and ammonium sulfate into the drum fermenter, add tap water to control the water content of the mixture in the drum fermenter to 30%, stir and mix evenly Afterwards, sterilize with pressure steam at 121°C fo...

Embodiment 2

[0039] The fertilizer is prepared as follows:

[0040] Step 1: Take 20 parts of Bacillus megaterium inoculum, 25 parts of jelly-like Bacillus inoculum, 20 parts of Saccharomyces cerevisiae inoculum, 20 parts of Lactobacillus acidophilus inoculum, and 20 parts of Trichoderma viride in parts by weight, The components are mixed to obtain a composite microbial agent;

[0041] Step 2: Take 20 parts of fish meal, 20 parts of soybean meal, 20 parts of corn flour, 30 parts of wheat germ flour, 10 parts of brewer's dregs, 2 parts of molasses, 6 parts of ammonium sulfate and the compound bacterial agent 5 prepared in step 1 respectively by weight Parts; add fish meal, soybean meal, corn flour, wheat germ powder, beer dregs, molasses and ammonium sulfate into the drum fermenter, add tap water to control the water content of the mixture in the drum fermenter at 35%, stir and mix evenly Afterwards, sterilize with pressure steam at 121°C for 20 minutes; then inoculate the obtained composit...

Embodiment 3

[0049] The fertilizer is prepared as follows:

[0050] Step 1: Take 18 parts of Bacillus megaterium inoculum, 18 parts of jelly-like Bacillus inoculum, 18 parts of Saccharomyces cerevisiae inoculum, 18 parts of Lactobacillus acidophilus inoculum, and 18 parts of Trichoderma viride in parts by weight, The components are mixed to obtain a composite microbial agent;

[0051] Step 2: Take 18 parts of fish meal, 18 parts of soybean meal, 18 parts of corn flour, 28 parts of wheat germ powder, 8 parts of beer dregs, 1.5 parts of molasses, 5 parts of ammonium sulfate and the compound microbial agent 4 prepared in step 1 respectively by weight Parts; add fish meal, soybean meal, corn flour, wheat germ powder, beer dregs, molasses and ammonium sulfate into the drum fermenter, add tap water to control the water content of the mixture in the drum fermenter at 32%, stir and mix evenly Afterwards, sterilize with pressure steam at 121°C for 20 minutes; then inoculate the obtained composite ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com