Method for producing mortar ash by using high-dopant fly ash and boron mud

A high-calcium fly ash and fly ash technology, applied in the field of industrial waste, can solve the problems of fast dehydration, high energy consumption, and high cost, and achieve the effects of simple process, low investment, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

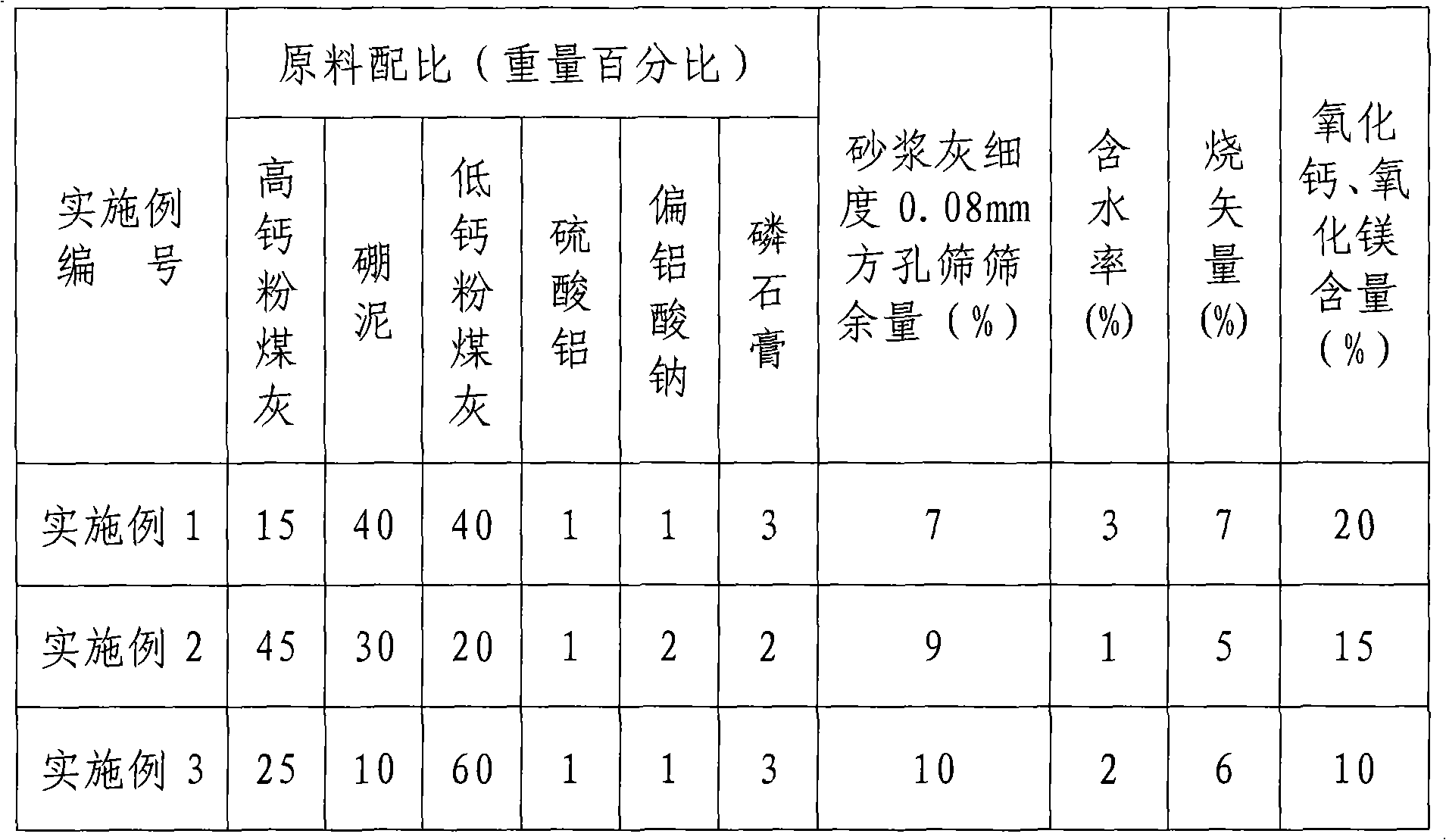

[0006] The specific embodiments of the present invention will be described in detail below in combination with the list.

[0007]

[0008] Add boron mud, phosphogypsum, aluminum sulfate and sodium metaaluminate to high-calcium fly ash and low-calcium fly ash according to the weight percentage required in the above list and grind to the required fineness. The mortar ash obtained in this specific example has been used in the office of Liaohua Energy Conservation Center, the residential buildings of Liaohua District 18 and 20, and the component factory of Chaoyang No. 2 Construction Company. Both parties A and B are very satisfied and have achieved considerable economic benefits. and social benefits.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com