Magnesium alloy plate machining method and magnesium alloy plate

A magnesium alloy and plate technology, which is applied in the processing of magnesium alloy plates and in the field of magnesium alloy plates, can solve the problems of limited application range, poor corrosion resistance, and low strength, and achieve the problems of expanding application range, solving low strength, and improving mechanical properties Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

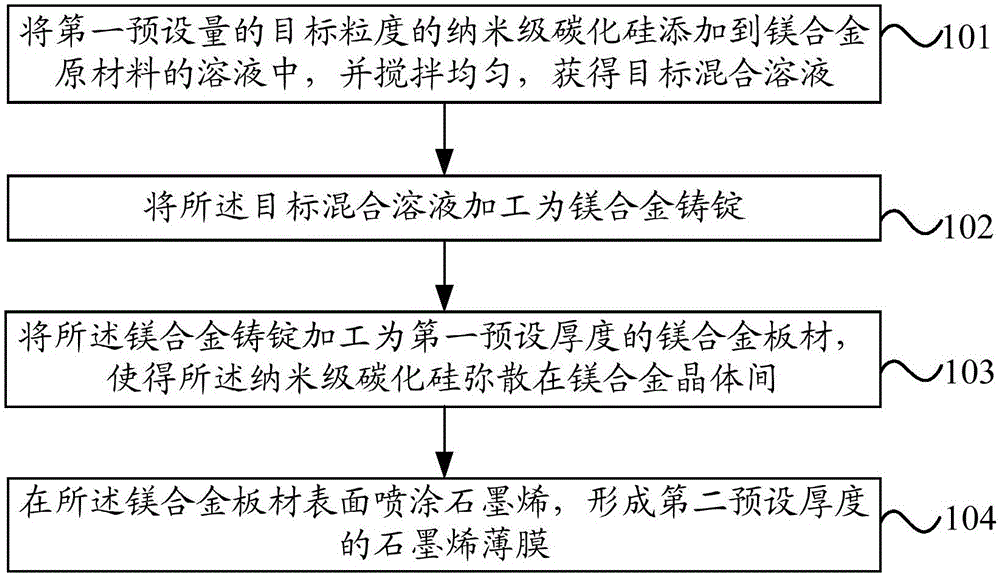

[0073] The embodiment of the present invention provides a kind of processing method of magnesium alloy plate, such as figure 1 As shown, the method includes:

[0074] Step 101: Add a first preset amount of nanoscale silicon carbide with a target particle size to the magnesium alloy raw material solution, and stir evenly to obtain a target mixed solution.

[0075] Among them, by controlling the total amount of nano-scale silicon carbide added to the magnesium alloy, the strength of the magnesium alloy plate obtained through final processing can be changed. However, the first preset amount added in the embodiment of the present invention is 0.1%-5% of the mass of the magnesium alloy raw material, which can make the magnesium alloy plate obtained by final processing achieve higher strength.

[0076] In addition, preferably, the target particle size is 50 nm to 70 nm. Among them, nano-scale silicon carbide with an average particle size of 50 nanometers to 70 nanometers can be ma...

no. 2 example

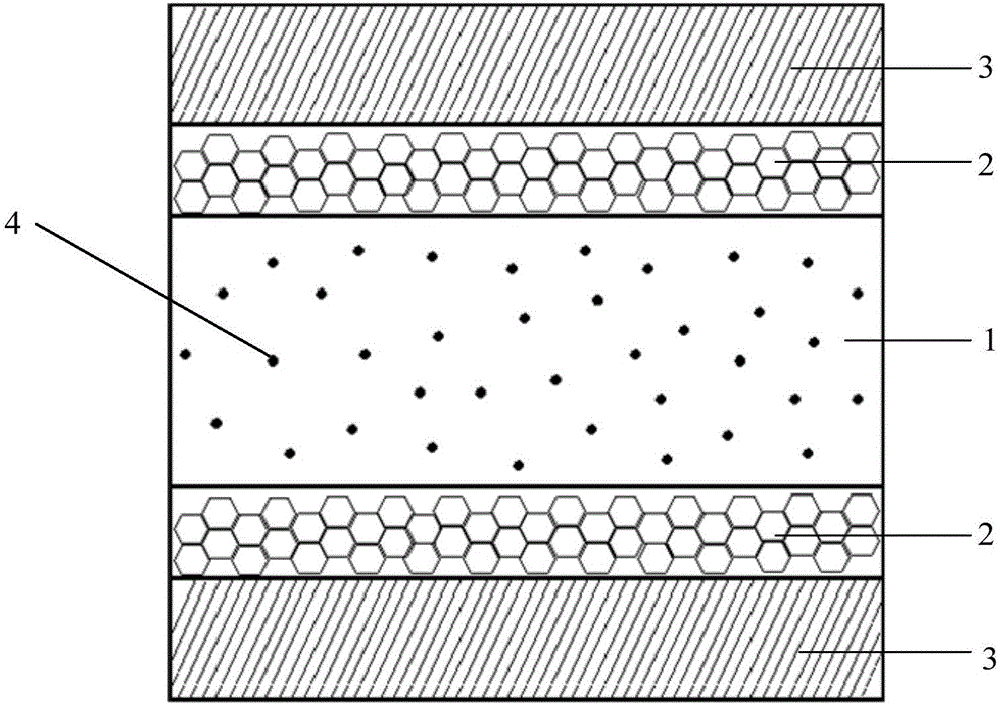

[0108] Embodiments of the present invention provide a magnesium alloy plate, such as Figure 2-4 As shown, the magnesium alloy sheet includes: a magnesium alloy substrate 1, the magnesium alloy substrate 1 includes magnesium alloy crystals and nano-scale silicon carbide 4, and the nano-scale silicon carbide 4 is dispersed among the magnesium alloy crystals;

[0109] A graphene film 2 covering the surface of the magnesium alloy substrate 1 .

[0110] Among them, the nano-scale silicon carbide 4 dispersed among the magnesium alloy crystals can play a role of dispersion strengthening and improve the strength of the magnesium alloy plate in the embodiment of the present invention. from Figure 5 From the curve shown, it can be seen that the yield strength and tensile strength of the strengthened magnesium alloy are greatly increased, the tensile strength is as high as 400 MPa, the formability is also greatly increased, and the elongation is as high as 15%. Further, the thickness...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com