Anticorrosive coating on substrate surface and preparation method thereof

An anti-corrosion layer and substrate technology, applied in anti-corrosion coatings, coatings, etc., to reduce infiltration, reduce water absorption, and improve anti-corrosion performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

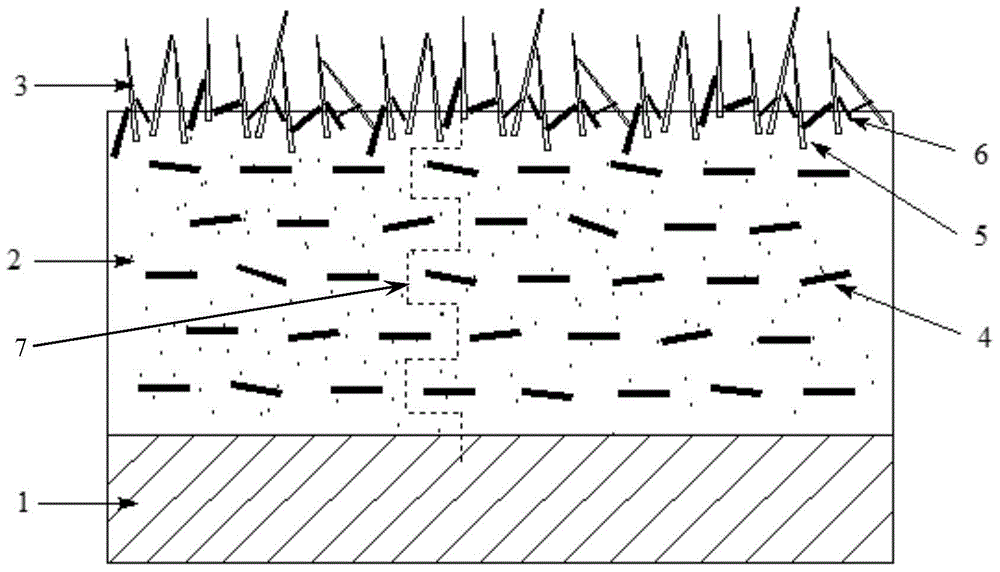

[0053] In this embodiment, the structure of the anti-corrosion coating on the surface of the substrate is as follows figure 1 As shown, it consists of an organic coating 2 on the surface of a substrate 1 and a hydrophobically modified glass flake assembly structure 3 adhered to the surface of the organic coating. The hydrophobically modified glass flake assembly structure 3 is composed of hydrophobically modified long glass flakes 5 and hydrophobically modified short glass flakes 6 . On the surface of the organic coating 1, hydrophobically modified short glass flakes 6 are intercalated between the hydrophobically modified long glass flakes 5, so that at least part of the hydrophobically modified long glass flakes 5 are embedded in the organic coating 2 at one end, The other end protrudes from the surface of the organic coating 2 to form a hydrophobic capillary structure with a sharp surface.

[0054] The preparation method of the anticorrosion coating on the surface of the ab...

Embodiment 2

[0061] In this embodiment, the structure of the anti-corrosion coating on the surface of the substrate is the same as that of the anti-corrosion coating on the surface of the substrate in Example 1.

[0062] In the present embodiment, the preparation method of the anticorrosion coating on the substrate surface comprises the following steps:

[0063] (1) Compatibility modification of glass flake E: short glass flake E is scaly C glass with a thickness of 1-4 μm and a length of 5-20 μm; Mix the ethanol solution at a mass ratio of 10:100 to prepare 1000mL of the solution, then add 500g of untreated short glass flake E, heat to reflux to 80°C, stir for 1h, then take it out, cool, wash, filter, and dry to obtain a compatible Sexually modified glass flakes.

[0064] (2) Hydrophobic modification of glass flakes F: glass flakes F are scaly C glass with a thickness of 1-4 μm, and its length is divided into two types, one is 5-20 μm in length, called “short glass flakes”, and the other...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com