Bearing structure and motor

A bearing and bearing inner ring technology, applied in the direction of ball bearings, shafts and bearings, bearing components, etc., can solve the problems of bearing electrical corrosion and bearing corrosion, and achieve the effect of eliminating potential difference and ensuring the ability to prevent electrical corrosion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

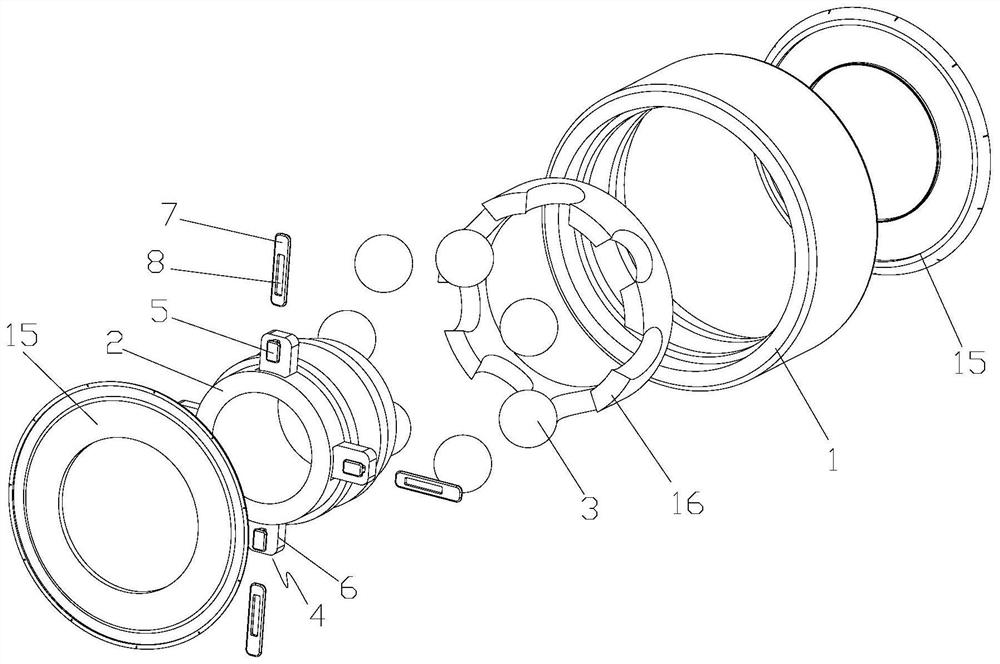

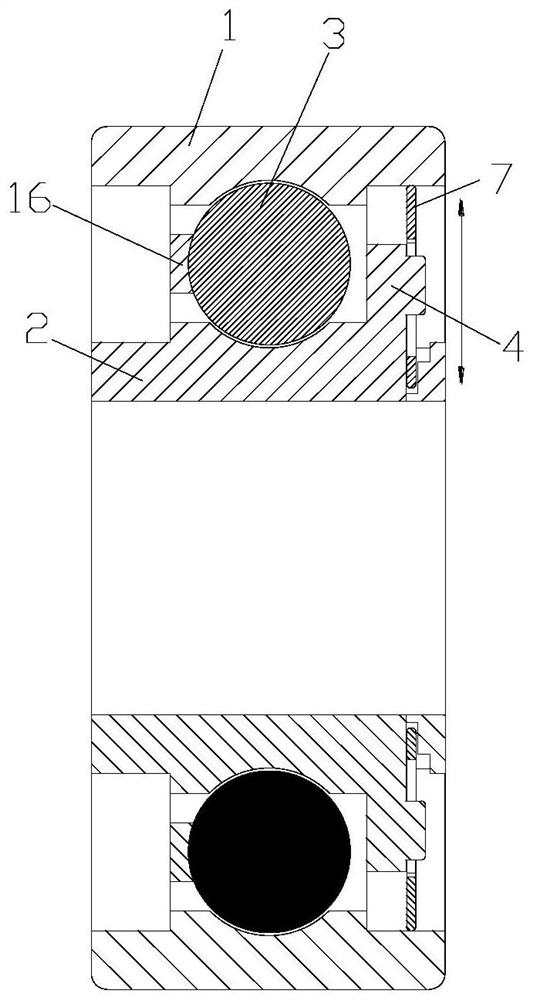

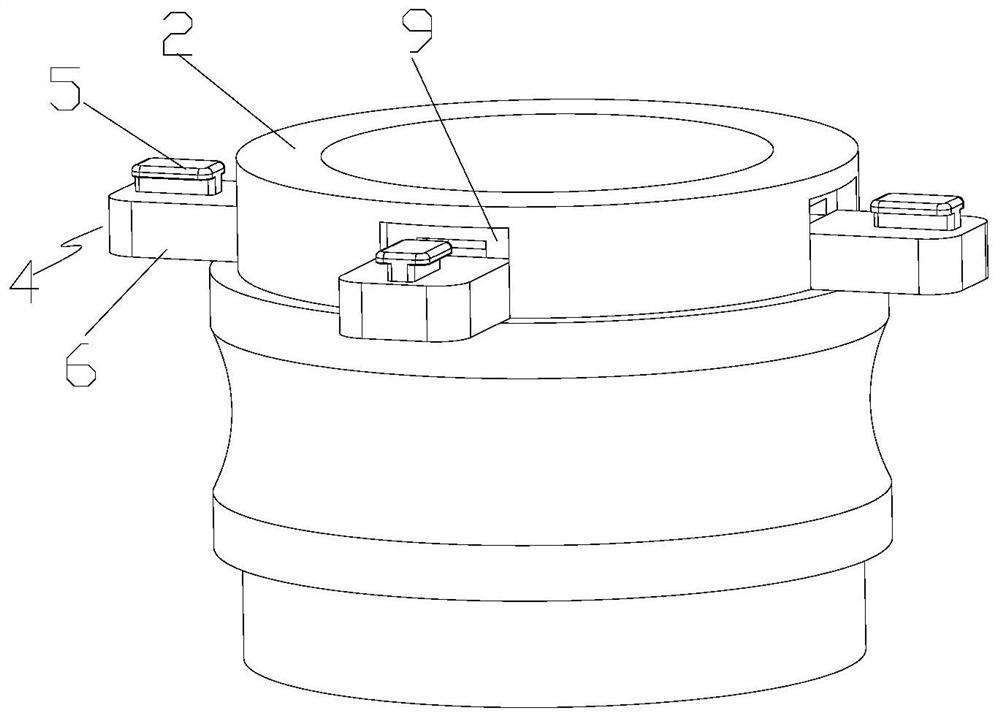

[0026] see in conjunction Figure 1 to Figure 6 As shown, according to the embodiment of the present application, the bearing structure includes a bearing outer ring 1, a bearing inner ring 2, rolling elements 3 and a conductive structure, the bearing outer ring 1 is sleeved outside the bearing inner ring 2, and the rolling elements 3 1 and the bearing inner ring 2 roll in the raceway, and the conductive structure is arranged between the bearing outer ring 1 and the bearing inner ring 2, and forms a conductive connection between the bearing inner ring 2 and the bearing outer ring 1.

[0027] The bearing structure directly connects the bearing outer ring 1 and the bearing inner ring 2 through the conductive structure, which can make the bearing inner ring 2 and the bearing outer ring 1 always in a connected state, and can always ensure that the bearing inner ring 2 and the bearing outer ring 1 The potentials are equal, and through this connection, the current will not flow thro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com